The measurable impact of AI on food safety

Posted: 15 August 2025 | Ian Westcott | No comments yet

Go beyond the hype of AI in food safety. This deep dive reveals where the real, immediate ROI lies: in automating compliance and unlocking the power of your existing data.

Instead of reacting to food recalls, modern AI in food safety allows for a proactive approach. By analyzing the immense information within a 'data lake,' predictive analytics can identify contamination risks in items long before they reach the consumer.

Twelve months ago, Artificial Intelligence (AI) in food safety was a topic of speculative hype. Today, with nearly 78 percent of organisations now using AI in at least one business function, according to a 2025 McKinsey report, the conversation has shifted dramatically from potential to performance. But as the industry moves past its initial scepticism, a crucial question emerges: where is this technology really making a tangible impact?

This article, building on insights from a pivotal IAFP symposium in Cleveland Ohio, cuts through the noise. While predictive modelling for pathogen outbreaks represents a vital long-term goal, we demonstrate here that the most significant and immediate return on investment for most food businesses lies in applying AI to a less glamorous but more urgent task: automating compliance, unlocking unstructured ‘dark data’ and fundamentally redesigning workflows.

The ‘why now?’: a perfect storm of need and opportunity

The shift from hype to practical application is no accident; its a direct response to the crushing complexity of the modern food system, with its web of global supply chains, intense regulatory scrutiny and immense operational pressure. This reality has created a fertile ground for AI-driven solutions.

A data culture isn’t about buying software; it’s about leadership fostering a sense of curiosity.

Crucially, this is not just an industry-led charge. Regulatory bodies are now active participants. As the US Food and Drug Administration (FDA)’s Mark Moorman stated at the IAFP panel, the agency is “really excited about this area” – a sentiment backed by active data-sharing partnerships with groups like Western Growers. This official endorsement provides a secure foundation for investment, transforming AI adoption from a speculative venture into a strategic imperative.

AI in action: from immediate wins to the next horizon

Understanding AI’s impact requires looking past the type of technology (machine learning, generative AI) to focus on the business problems it solves. When viewed through this lens, a hierarchy of opportunity emerges, starting with the most immediate and accessible wins.

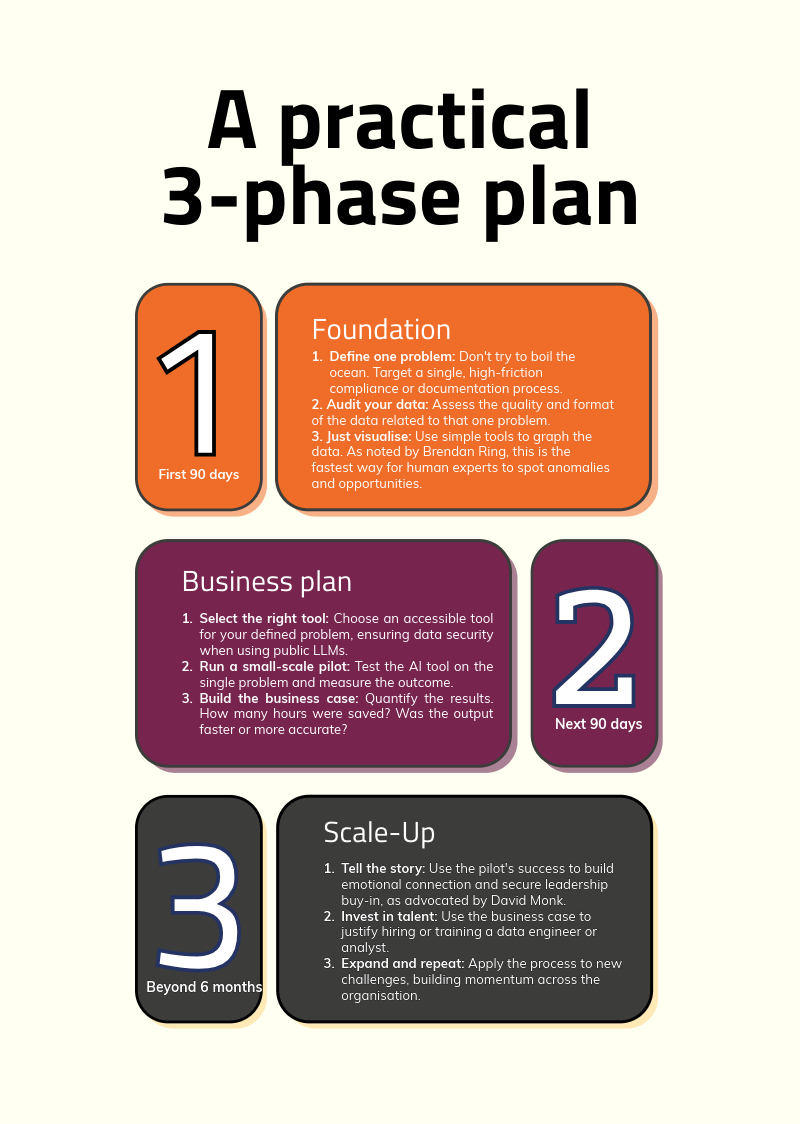

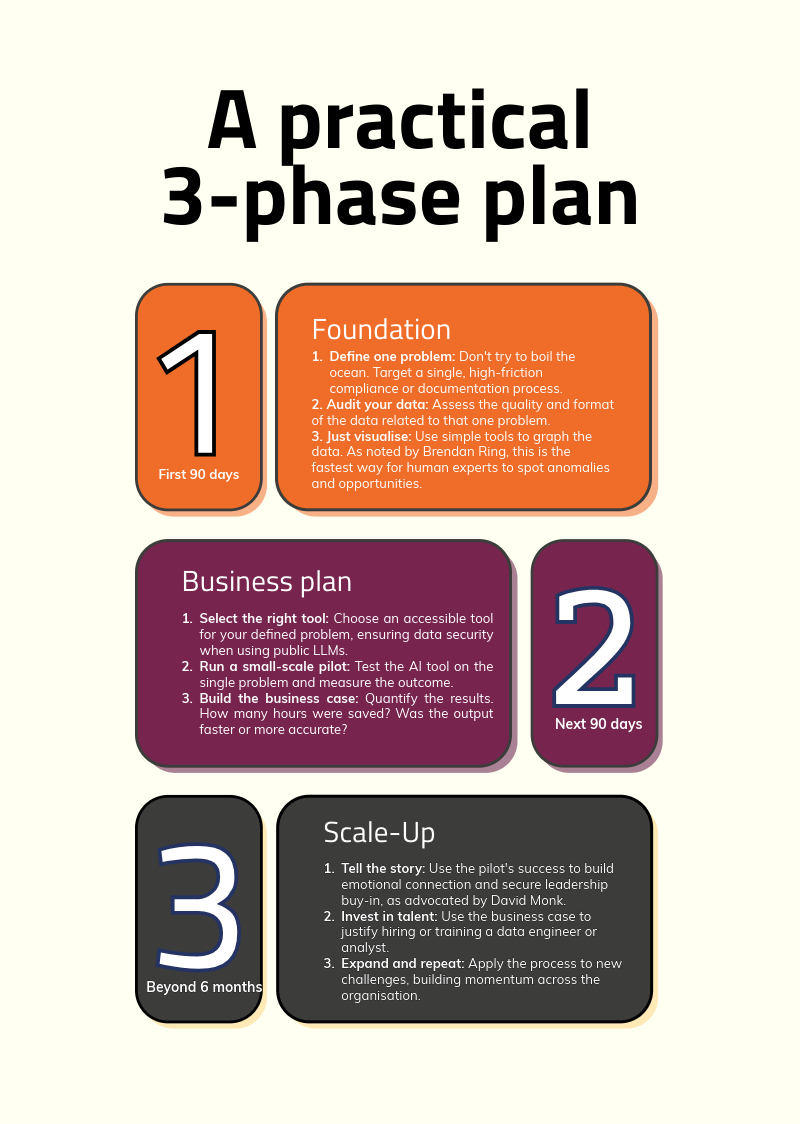

A structured, three-phase approach can guide a business from initial planning to successful AI adoption. This roadmap highlights the key actions needed at each stage, from foundational data audits to building a compelling business case.

Automating compliance & unlocking ‘dark data’: the immediate ROI

For many food businesses, the most valuable and immediate AI revolution is not in predicting the future but in mastering the present. The real opportunity lies in unlocking ‘dark data’: the valuable intelligence trapped within unstructured sources like audit reports, supplier certificates and inspection notes that every company already possesses in abundance.

A prime example of this principle is in operational hygiene management. As detailed by Ecolab’s Amani Babekir, a dynamic environmental swabbing plan generates a constant stream of microbial data. Replacing the work of a manager to manually interpret these results and devise a response, a generative AI model can now process unacceptable swab results instantly, performing a targeted root cause analysis and a list of clear corrective actions. This moves the process from a slow manual review to an immediate strategic intervention, turning raw data into actionable safety.

The AI journey in food safety doesn’t have to start with an expensive, high-risk moonshot project.

The principle extends beyond internal data to the complex web of external regulation. Updating legislation across multiple languages is a notoriously cumbersome process. Brendan Ring of Creme Global highlighted a transformative case study from Dubai where AI is used to convert dense legal documents into simple, accessible AI-generated podcasts. By feeding the current legislation and proposed changes into a tool like NotebookLM, a clear audio summary is created and translated, making it simple for all stakeholders to understand. Thus, what was once a multi-year process of alignment becomes achievable in weeks.

Driving operational efficiency & proactive control

Once data is unlocked, AI can be applied to streamline physical operations. Chick-fil-A, a fast-food restaurant chain managing immense complexity, uses machine learning with ambient temperature sensors to accurately predict internal product temperatures when direct measurement is impossible. This provides crucial data during events like power outages, shifting their control from reactive to proactive. This practical application moves AI from the back office to the kitchen floor, ensuring safety and reducing waste.

The next horizon: advanced predictive modelling

With a strong data foundation in place, the much-hyped goal of predictive analytics becomes achievable. This is the next horizon of AI maturity. Ecolab, for example, uses historical audit and swabbing data to predict a retail store’s future compliance level, enabling focused, preventative intervention before a problem arises. Similarly, Chick-fil-A uses advanced models to forecast Salmonella growth, accounting for complex variables like chicken morphology to refine its safety protocols.

The ultimate goal: collaborative intelligence

The pinnacle of AI application is the creation of collaborative data ecosystems. Initiatives like the Food Industry Intelligence Network (FIIN), where over 70 companies anonymously share sensitive product testing data, allow AI to spot aggregated trends and potential hazards that no sole company could ever see in isolation. This shared intelligence, built on a foundation of data trusts, represents the ultimate strategic advantage.

The foundation: mastering your data and people

Embarking on an AI journey without the right foundation is a recipe for failure, as Chick-fil-A’s account of its first failed ‘data lake’ attests. The model produced nonsensical predictions because the underlying data had not been properly structured. Success depends on two pillars: data and people.

The ‘garbage in, garbage out’ problem is the first hurdle. As the IAFP panellists agreed, success begins with clean, contextualised data and the specialised talent of data engineers who can build systems for efficient data retrieval. The latest McKinsey data confirms this to be a critical challenge, with roles like data scientists and data engineers remaining in high demand and difficult to fill as companies scale their AI efforts.

Beyond technology, however, is the need for a data culture. This requires leadership to foster a sense of curiosity and grant what the FDA’s Mark Moorman calls “permission to try new things.” This human element is critical. AI supports, not replaces, human expertise. The indispensable partnership between a data scientist and a subject matter expert is what gives AI-generated insights real-world meaning and guards against model ‘hallucinations.’

AI readiness roadmap: a practical 3-phase plan

For a technical leader wondering where to begin, the path forwards can be broken down into a practical plan. This aligns with McKinsey’s 2025 findings that while a majority of business units now report cost reductions from using generative AI, most companies are not yet seeing enterprise-wide bottom-line impact. This highlights the importance of starting with targeted, high-value pilot projects.

Phase 1: Foundation (first 90 days)

- Define one problem: don’t try to boil the ocean. Target a single, high-friction compliance or documentation process.

- Audit your data: assess the quality and format of the data related to that one process.

- Just visualise: use simple tools to graph the data. As noted by Brendan Ring, this is the fastest way for human experts to spot anomalies and opportunities.

Phase 2: Pilot (next 90 days)

- Select the right tool: choose an accessible tool for your defined process, ensuring data security when using public LLMs.

- Run a small-scale pilot: test the AI tool on the single process and measure the outcome.

- Build the business case: quantify the results. How many hours were saved? Was the output faster or more accurate?

Phase 3: Scale-Up (beyond six months)

- Tell the story: use the pilot’s success to build emotional connection and secure leadership buy-in, as advocated by David Monk.

- Invest in talent: use the business case to justify hiring or training a data engineer or analyst.

- Expand and repeat: apply the process to new challenges, building momentum across the organisation.

Food manufacturing’s new reality

The most pragmatic and powerful first step is to turn AI’s capabilities inward: automate the burdensome tasks of compliance and unlock the intelligence in the data you already own. By delivering clear, immediate ROI on these foundational challenges, food businesses can build the momentum, capability and trust required to tackle the next horizon of predictive food safety.

Related topics

Related organisations

Chick-fil-A, Crème Global, Ecolab, Food Industry Intelligence Network (FIIN), IAFP, McKinsey, NotebookLM, US Food and Drug Administration (FDA), Western Growers