CO2 laser processing: a technology to improve food safety

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 29 December 2022 | Eduardo Puértolas, Izaskun Pérez, Xabier Murgui | No comments yet

How could CO2 laser processing transform food production of the future? Find out how this contact-less technology might help here…

Technological innovation in processing is one of the fundamental pillars on which the improvement of the efficiency and profitability of the food industry hinges. Among the technologies studied in recent years, the CO2 laser has remarkable capacity to transform the food production of the future.

Temporal and spatial precision of lasers make it possible to concentrate the laser energy in a tiny spot and follow complex patterns, without overly impacting nearby food material.

This is particularly of interest in several mechanical and thermal processes. For instance, it has been proposed to inactivate microorganisms on food contact surfaces. It can also be used for non-contact cutting, avoiding the physical, chemical and microbiological cross-contamination problems of other systems such as blades or water jet; or for food marking, replacing paper/plastic labels and inks.

CO2 laser: main properties and effects on foods

A laser (an acronym for light amplification by stimulated emission of radiation) consists of an energy supply system that energises the molecules of a gain medium to an excited state, producing light.

This light is amplified in an optical cavity restricted by two mirrors, one of each partially transparent letting pass a coherent and directional laser beam, which can be focused on the target material with temporal and spatial precision by a lens system controlled by a software.

Carbon dioxide (CO2) lasers were given their name because they use CO2 as the main component of the gain medium, emitting a laser beam in mid-infrared wavelengths (typically 10,600 nm).

Infrared wavelengths are transmitted almost without loss in the atmosphere. Furthermore, they can be effectively absorbed by water, which is the main component of foods. Thus, both are likely to be the main reasons of the interest that CO2 lasers have received in food processing.

By modulating the radiant energy of the CO2 laser beam, photochemical, thermal, and mechanical effects are progressively produced in the food.1 If CO2 laser energy is low, the laser only disturbs the bonds between atoms and between molecules. At higher radiant energy, the laser beam energy is converted into thermal energy, heating the surface of the food (a depth of a few millimetres) in a precise and controlled manner.

By further increasing the radiant energy, direct mechanical effects can be produced on the food surface, eventually forming a crater based on vaporisation and ablation phenomena.1

The ablation process can be repeated in the lower layers of the food, enabling it to go deeper into it, or/and continue in the adjacent zones following a specific pattern. Based on these effects, the CO2 laser can be used for a wide range of food applications including microbial decontamination, cooking, marking, and cutting.

Microbial decontamination

The CO2 laser is a non-contact and relatively fast technology to inactivate microorganisms on the surface of different substrates and is an alternative to traditional surface cleaning and disinfection systems, such as the use of chemicals, a solution that is increasingly being questioned due to possible toxic residues.

For food contact surfaces (e.g. cutters, conveyor belts) heating is not a major problem and laser accuracy and processing speed can play a major role. For example, total inactivation of Escherichia coli and Staphylococcus aureus has been reported in stainless steel surfaces after CO2 laser treatments (660 W; 0.8-1.3 cm/s).2 Apart from the microbial inactivation, the mechanical effects of the CO2 laser can also help to remove hard-to-clean organic matter and biofilms from these types of surfaces.

CO2 lasers are also capable of inactivating microorganisms present on food surfaces.3 However, in this case, the treatments must be very well optimised to minimise the impact on their surface characteristics, avoiding mechanical effects and minimising the thermal effects.

Despite optimisation, surface changes, such as colour alterations, are usually detected. The use of flavonoids, riboflavin or other antioxidants could reduce or even avoid these adverse effects.4

Thermal processing

The CO2 laser can be used as an alternative to conventional thermal technologies for cooking, grilling and browning, taking advantage of the high energy of the light beam.4-5

However, in this case, the carbonisation and ablation processes (thermal and mechanical effects, respectively) associated with high-energy intensity treatments should be avoided.

In food products cooked with CO2 laser, microbial reductions in Salmonella Typhimurium, Salmonella Senftenberg and Escherichia coli O157:H7 are observed, similar to those obtained with common cooking methods, such as infrared oven, electric barbecue or electric flat grill.3 If CO2 treatment is adjusted to reduce carbonisation, laser-cooked foods also present a similar amount of polycyclic aromatic hydrocarbons than conventionally cooked foods.3

The precision of the CO2 laser means that only one of the food parts can be cooked (e.g. only the fatty portion of a piece of bacon), or even each part of the food at its optimal conditions (temperature, time), changing on the fly the treatment energy and the exposure time.5 In this context, CO2 laser has received special attention in the 3D printing of foods, where precise heat delivery is needed for cooking pre-printed food.5

The authors’ note that the precision of the CO2 laser means that only one of the food parts can be cooked such as the fatty portion of a piece of bacon.

The laser energy only penetrates a few millimetres into the food, meaning it has been proposed for cooking thin foods or for surface treatments such as grilling or browning. For many products, combined use with other technologies such as microwaves has been proposed, using lasers for surface finishing (e.g. grill marks).3

Marking foods

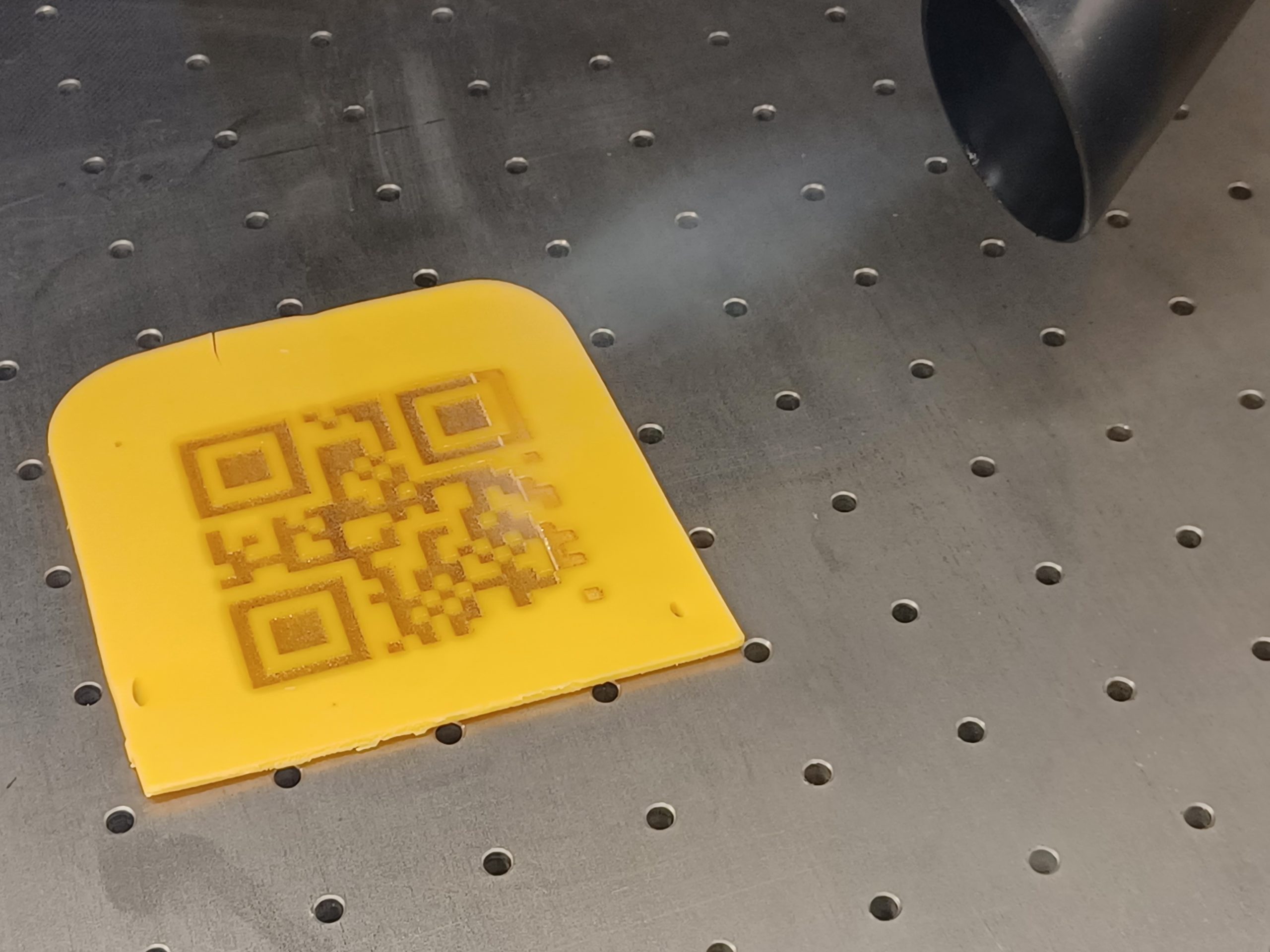

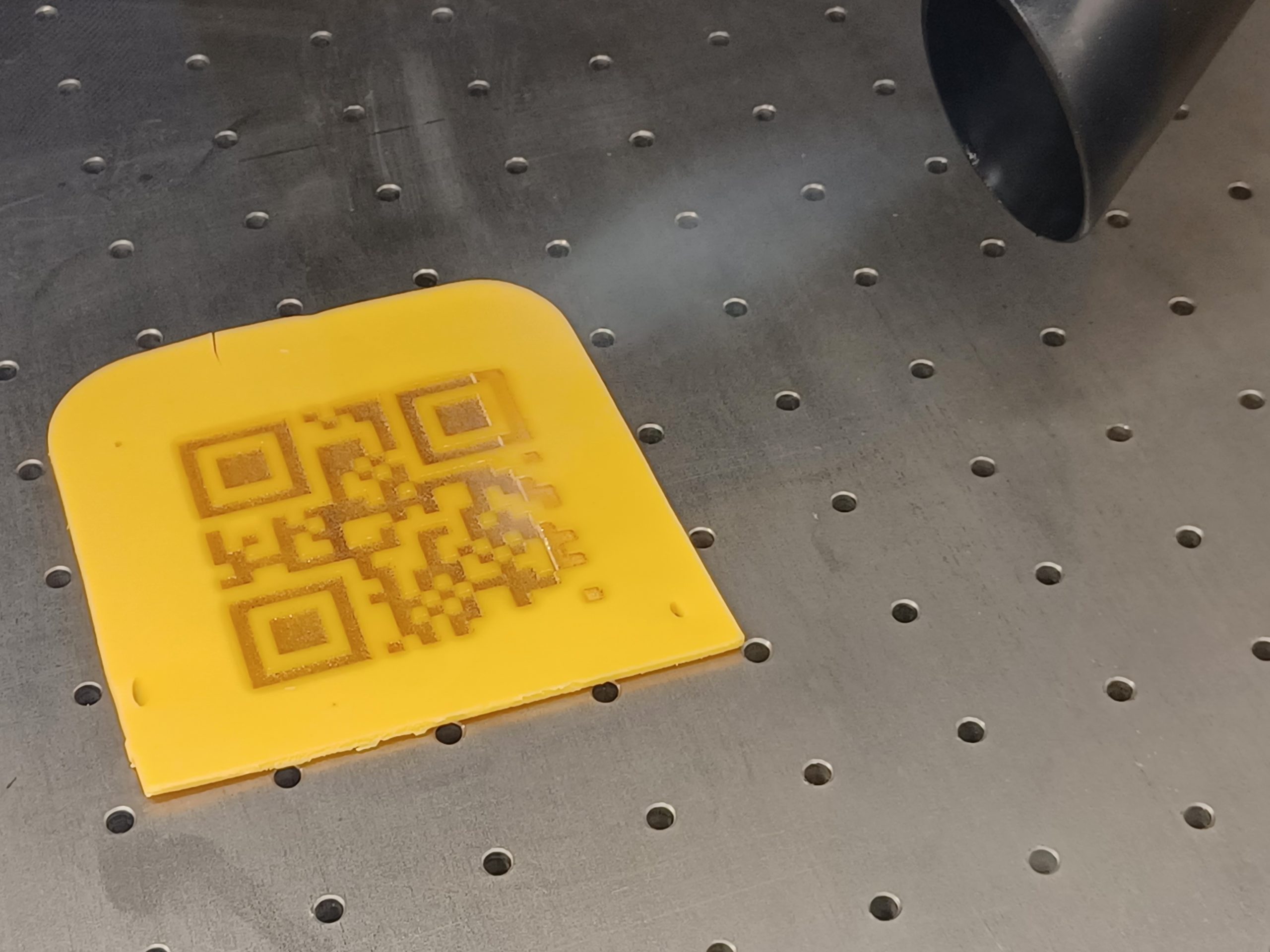

The use of laser for fruit and vegetable marking is authorised and implemented in the industry in several European countries. They have been tested in a wide number of foods, including fruits, vegetables, eggs, meat, cheese, chocolate and cereal products (Figure 1).

Figure 1: Marking of a QR code by CO2 laser in cheese (example of laser processing).

Its interest lies in the fact that it does not require plastic/paper labels or adhesives and that it is made to avoid any contact. From a general point of view, CO2 lasers can be used for marking based on their mechanical (engraving) or thermal effects (Maillard reaction).

In both cases, it is possible to operate the laser following almost any pattern, so it is possible to mark numbers (e.g. expiration date, batch number), letters (e.g. place of origin, company name), codes (e.g. barcode, QR) or intricate drawings or designs (e.g. quality label, company logo).6

Mechanical food processing: cutting, peeling and perforation

Relying on the ablation phenomenon, the CO2 laser can be used as a non-contact technology for cutting and peeling or for other mechanical procedures such as perforation that can be used in some operations such as marinating or extraction of compounds.1,4

Advantages

CO2 laser presents several advantages over conventional techniques involving blades, knives, needles or similar devices.

Firstly, the processed area is partially decontaminated due to the action of the laser beam (microbial inactivation), a key advantage for food safety compared to blade or waterjet cutting.

It is also possible to process foods according to complex patterns that are difficult or even impossible to achieve with conventional techniques.

Finally, a change of pattern can be made on the fly and there is no need to stop the line to clean the mechanical cutting element. In conventional technologies, the cleaning process or any change in the cutting configuration involves stopping the line to clean, change, replace or move the cutting elements.

Limitations

The most important limitations of the use of CO2 laser for this kind of mechanical processes are the heat generated and the relatively shallow depth of cut.

Effective selection of the laser processing parameters is key to avoid burning the cut edges of the food and for proper performance. For a depth of more than a few millimetres, several laser processing cycles are needed to allow sufficient time for the zone to cool. Other strategies are based on direct cooling of the laser-treated zone by using water or steam.

How will it benefit the food industry?

CO2 laser is a contact-less processing technology with a lot of potential for reducing cross contamination problems in the food industry.

It could be used in foods for a wide number of applications, such as cooking/grilling, marking, cutting, and peeling or for inactivating microorganisms presented on food contact surfaces.

To the authors’ knowledge, the only laser application that is fully industrialised and widespread in the food market, for direct action on food, is the laser marking of fruits and vegetables.

However, the results obtained in the other applications are promising, further effort is needed to bring them to market. Today there are CO2 laser systems with the necessary power and characteristics to industrialise most of the applications described in this article.

Thus, no major scaling problems are to be expected and it is foreseeable that their industrial use will begin to spread in the coming years. Since CO2 lasers are used in other industrial sectors, their cost has significantly decreased in the last two decades.

With this in mind, the cheaper cost will undoubtedly facilitate their implementation in the food industry, where margins are lower than in other production sectors.

References

- Puértolas, E., et al. (2020). Emerging Extraction. In Food Waste Recovery, 219–240. 2nd ed. San Diego: Academic Press.

- Watson, I., et al. (2007). Scanning CO2 laser bacterial inactivation systems. Journal of Applied Microbiology 102:766–773.

- Gràcia, A. (2019). Laser cooking system applied to a 3D food printing device. PhD thesis, Universtat Autònoma de Barcelona.

- Teng, X., et al. (2021). Potential applications of laser technology in food processing. Trends in Food Science & Technology 118:711–722.

- Fukuchi, K., et al. (2012). Laser cooking: a novel culinary technique for dry heating using a laser cutter and vision technology. In CEA ’12: Proceedings of the ACM multimedia 2012 workshop on Multimedia for cooking and eating activities, 55–58.

- Henze, N., T., et al. (2015). Augmenting food with information. In MUM ’15: Proceedings of the 14th International Conference on Mobile and Ubiquitous Multimedia, 258–266.

About the authors

Eduardo Puértolas (ORCID: 0000-0001-7489-4674) is a PhD researcher at the Food

Izaskun Pérez is an agricultural engineer and researcher at AZTI-

Xabier Murgui, agronomist engineer and Master in Technology and

Related topics

Equipment, Food Safety, Health & Nutrition, Hygiene, Lab techniques, Processing, Product Development, Research & development, Supply chain