The role of enzymes in the emerging sustainable food system

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 9 September 2022 | Angelica Schiavone, Shekhar Kadam | No comments yet

Shekhar Kadam and Angelica Schiavone of Kerry Group explore the wonderful world of enzymes and explain how these biological catalysts can contribute to a sustainable food and drink industry.

Today, the global food system is responsible for over 30 percent of greenhouse gas emissions, with food loss and waste alone accounting for eight to 10 percent. By 2050, our global population is expected to swell to almost 10 billion people; coupled with rising incomes and urbanisation, demand for animal-based protein will grow.

The World Resources Institute has predicted that we will require 50 percent more food by 2050, as well as 70 percent more animal-based protein, to feed the planet.

This means we must revolutionise global food production as well as manufacture and consumption practices. Failure to do so would require landmass twice the size of India to be converted to agriculture, over the next three decades, leading to significant deforestation and biodiversity loss. It would also result in a failure to meet the Paris Agreement goal of keeping global warming below 1.5°C.

As the world confronts climate change, we now have a striking opportunity and obligation to create a more inclusive, resilient and sustainable food system, while still feeding an additional two billion humans. Enzymes can play a vital role in pursuing this goal.

It’s all about enzymes

On this sustainability journey, enzymes have become an increasingly important ally due to their high efficiency and specificity, and their ability to create a more efficient food manufacturing and production system. Kerry is working to develop and harness new enzymes for many different amazing applications.

The use of enzymes in food preparations is an age-old process. For millennia, humans –unknowingly at first – used enzymes to their advantage in cheese making, brewing and bakery. The term ‘enzyme’ was first coined in 1877 by Wilhelm Kühne and is derived from the Greek word for ‘in leaven’ (enzymos).

The original purpose of including enzymes in manufacturing processes was to improve the efficiency of the process and reduce costs. However, it is now well established that enzymes have far more to offer and can unlock significant sustainability benefits while enhancing product quality. In most cases, Kerry enzymes are used in food production as processing aids, where they aid in manufacture but do not have a function in the final product.

Improve product quality and operational efficiencies

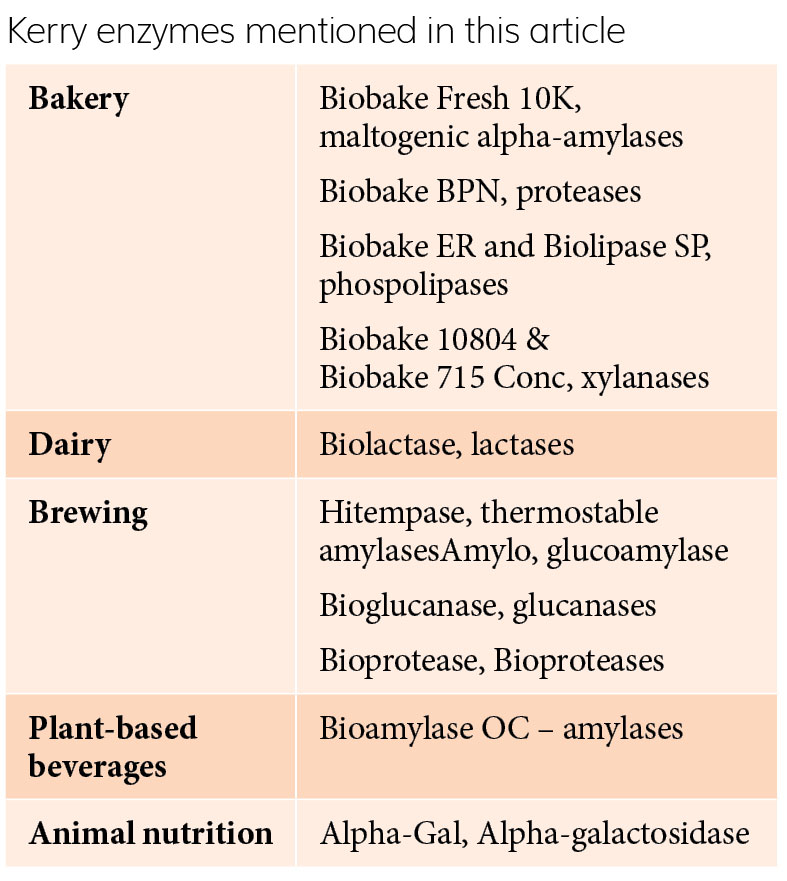

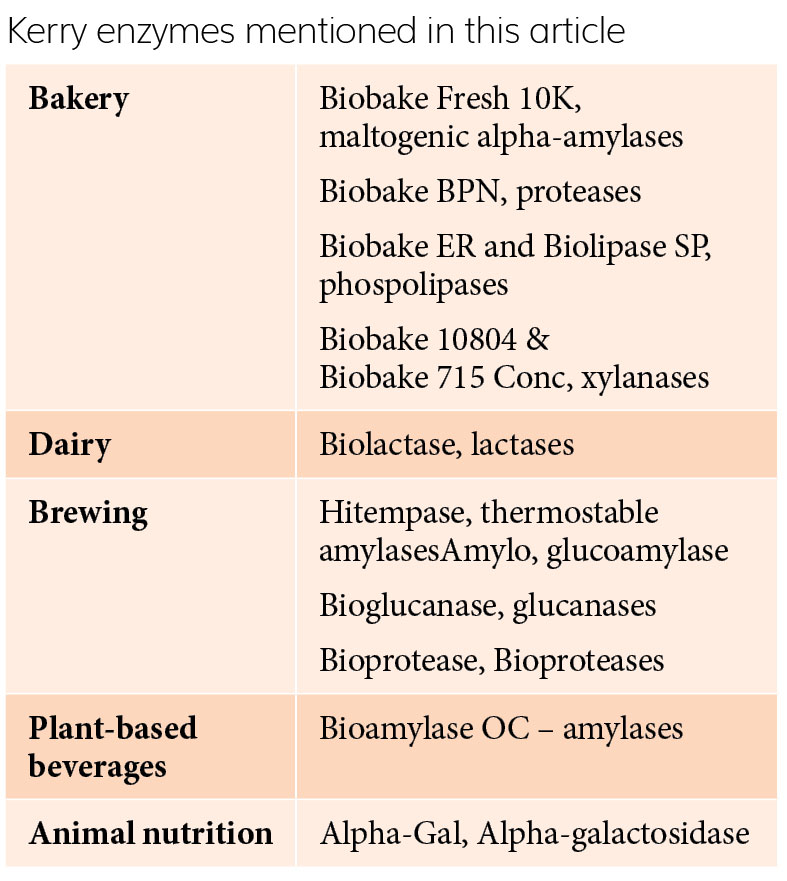

In the baking industry, different types of Kerry enzymes (amylases, proteases, lipases, xylanases and many others in development – for Kerry enzymes mentioned in this article see Table 1) add a number of valuable functionalities and properties to the final product. These include improved shelf life, freshness, softness, flavour, dough uniformity and gluten strength, to name a few. In brewing, haze-negative proteases reduce haze in the final beer and improve shelf life; in dairy production, lactase enzymes enable the manufacturing of lactose-free products for lactose-intolerant consumers; and in the animal nutrition industry, alpha-galactosidase has been shown to improve the nutrient digestibility of feed.

Amylase, glucanase and glucoamylase enzymes enable food and beverage manufacturers to speed up production processes and improve yields, significantly lowering energy use and water consumption. Through their use, manufacturers can reduce production time by 25 percent and utilise a wider range of raw materials, improving extract yields, increasing volumes and reducing carbon footprints. In fact, these Kerry enzymes are already used widely in the production of dairy-alternative plant-based beverages.

Table 1

The growing preference for plant-based food and beverages requires new enzymes that can provide plant-based protein sources with the functional attributes of animal-derived protein while improving the taste and texture of final products. With their ability to increase the stability of plant-based nutritional beverages, optimise process conditions, and allow for the production of finished products with consistent mouthfeel, reduced sugar and better taste, the future of enzymes looks bright.

Foster local, sustainable raw materials

Enzymes enable a wider variety of raw materials to be used in a range of processes. In the brewing industry, for example, the most common grain used globally is barley. However, as a cool season, temperate-climate cereal, it’s not widely grown in many parts of the world. Today, the use of exogenous enzymes enables brewers to employ alternative local grains for brewing; options such as sorghum, maize, rice and cassava can produce a consumer-acceptable beer at an economically attractive price.

Thermostable α-amylase for high-adjunct brewing, along with glucanase, proteases and glucoamylase, facilitates the use of alternative, unmalted, local and sustainable raw materials – which are also more cost-effective. The added bonus is zero impact on final product integrity.

In the UK we throw away almost 900,000 tonnes of bread every year, but by increasing the shelf life of baked goods with enzymes by just two days we can reduce this number drastically

Using regional grains delivers a significant advantage to the local economy: it creates employment; provides incomes for local farmers; and supports the overall economy. Cassava, for example, is a starch-rich tuber crop grown primarily in Nigeria, Brazil, Indonesia and Thailand that is currently underused in beer production. In addition, locally sourced, low-cost cassava represents a potential alternative source of sugar for syrup extract makers, brewers, distillers, confectioners and ethanol producers. With optimal application of thermostable amylases and glucoamylase, extracts of the desired quality can be unlocked from the cassava tuber for use as a high-quality, affordable, sustainable alternative to imported barley.

Significant environmental benefits

An estimated one-third of all food produced is lost or wasted. According to the World Food Programme (WFP), reducing food waste could save enough food to feed two billion people – more than twice the number of people currently undernourished, while also making a substantial contribution to addressing climate change.1

Enzymes can help reduce wastage by:

- Extending the shelf life of staple foods such as bread

- Transforming waste streams into value-added products

- Improving overall production efficiency and the quality of final products.

Bakery

The global bakery industry represents the largest volume of food waste. Increasing the shelf life of baked goods by just two days with enzymes can reduce the volume of wasted items by 40 percent. And enzymes not only reduce waste, they improve production efficiencies and enhance the quality of baked goods.

Amylases can break down starch to smaller molecules to improve softness over shelf life, while xylanases hydrolyse non-starch polysaccharides (like arabinoxylan and hemicellulose) so that insoluble hemicellulose is converted to soluble hemicellulose; this improves water-holding capacity, gluten development and elasticity. In doughnuts, for example, some specialised enzymes can double shelf life without impacting softness, moisture, volume and other desired sensory attributes.

Meat and fish

Meat, the most carbon-intensive category of food waste globally, is also the highest-value offender. Globally, some 20 percent of meat production is wasted.

Specific protease enzymes can help meat processors efficiently transform waste into valuable resources for use in a variety of applications, including biofertilisers. Proteases valorise animal by-products that would otherwise be waste‑bound, helping meat processors become more sustainable. In the similarly waste-challenged fish industry, advances in enzyme technology now facilitate the conversion of protein-rich offal into cost-efficient fish oils and proteins, creating value from what were formerly waste products. Enzymes are fast becoming a hero in the circular economy due to their ability to turn waste into potential revenue streams.

Brewing industry

Brewing presents environmental challenges, both during production and in the waste management phase. The largest waste by volume is brewers’ spent grain (BSG), followed by yeast. Every tonne of BSG in landfill releases 513kg CO2 equivalent of greenhouse gases. This by-product of the brewing process has extraordinary circular-economy potential, making it a perfect candidate for upcycling into human food supply or feed, or for pharmaceutical purposes.

The use of exogenous enzymes enables brewers to employ alternative local grains, such as maize and rice, for brewing

Exogenous enzymes, such as amylases, proteases and non-starch polysaccharides (NSP) can help improve extract yields, reducing waste and enabling the re-use of waste or conversion of by-products such as spent grain into value-added products. These enzymes hold great potential to help cereal‑based products manufacturers – and breweries in particular – looking to valorise the by-product waste stream and convert it into value‑added products by reutilising unpurposed proteins and fibre molecules.

Overall, enzymes and processing aids deliver a significant reduction in brewing energy consumption and CO2 emissions. There is potential for 19 percent energy savings and 41 percent CO2 emission reduction by using enzymes and processing aids at different stages in the brewing process.

Excellent future prospects for enzymes

In the future, food production will rely on advances in microbiology, artificial intelligence and bioprocessing. Of these various scientific and technical advances, enzymes hold extraordinary power to play a role in the sustainable future of food, making it healthier and adding value to waste streams.

With advancements in enzyme bioengineering, these natural biocatalysts are quickly finding pivotal use as tools in capturing agri-food and by‑product waste, unlocking the recovery of essential nutrients, and, in many cases, converting previously valueless waste streams into substantial revenue returns. When you combine this incredible potential with an accelerating consumer focus on health, environment and sustainability, and the ongoing research and innovation focus around optimising enzyme use, it becomes clear that the job of enzymes is to positively disrupt our food system – and then facilitate the construction of a more efficient and sustainable food chain.

About the authors

Reference

- www.wfp.org/stories/5-facts-about-food-waste-and-hunger

Issue

Related topics

Ingredients, Natural, Processing, Sustainability, Technology & Innovation

Related organisations

Kerry Group, United Nations World Food Programme (WFP), World Resources Institute