Rosy past, present and future

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 16 June 2019 | Anna Lambert | No comments yet

Anna Lambert, food industry writer, reports on Salumificio Viani’s state-of-the-art production process, which combines centuries-old techniques with artisanal know-how to ensure the sweet taste and warm pink hue of the Tuscan prosciutto it produces.

Away from the rolling hills of Tuscany on a less-than-prepossessing industrial estate a short drive from Siena, an ongoing culinary alchemy is taking place. Here at Salumificio Viani, a family business that began in 1922 as a simple butcher’s shop and now employs over 100 staff , Prosciutto Toscano DOP is produced to grace tables around the world. It’s a painstaking process, as third-generation family director Marta Viani explains: “It’s about time, it’s about patience and it’s about being absolutely sure of the quality of your product.”

It begins with the pig

The elemental genesis of prosciutto production is, of course, the pig. Twenty-one farmers in the region supply Viani with approximately 100,000 hams per year, from crossbreeds of Duroc Italiana, Large White Italiana and Italian Landrace pigs. They are bred to the specifications of the Consorzio del Prosciutto Toscano (The Tuscan Ham Consortium). This is a body comprised of local producers who came together in 1990 to promote, enhance and protect their products by ensuring close links with the territory they come from, which resulted in it receiving coveted DOP status in 1996. According to Consorzio rules, pigs whose hams make it into the Viani factory for DOP-status products must have been born, bred and slaughtered in Tuscany or its nearest neighbours; will be a minimum of nine months old; and will have been fed on a diet of specially chosen grains to ensure optimal health. Only pigs weighing between 146 and 177kg while living are suitable.

Even if they meet those criteria, though, it’s not a given that they’ll wind up on the production line: the fresh hind legs are inspected to ensure they adhere to the selection requirements set out by the Consorzio, that they are imperfection-free and of the requisite size and shape.

The prosciutto factory process

Upon satisfying these strict criteria, selected legs then pass through to the factory floor, where they are hand trimmed to give each ham its typical round shape, with fat and rind being removed in a particular way: “It’s the V-shape we create that’s typical to Tuscany and key to the process,” explains Marta. “Taking away more of the fat improves salt absorption, giving our prosciutto its special flavour.”

Wastage at this stage is minimal: fat offcuts are used in Viani’s salami-production line, while meat offcuts are sold on to pet-food manufacturers.

Once the trimmed hams have been tattooed with their batch numbers and shot through with the Tuscan

Black pepper adds flavour and has antibacterial properties

POD metal disc, excess blood is pressed out of them and they are salted by both machine and – most importantly – hand. “This stage is vital because the salt must be massaged carefully into every crease of the ham – otherwise that area won’t cure properly,” stresses Marta. “And the only chemical we use in the preservative process is salt, simple salt. We do add a special mix of bay leaves, juniper berries and garlic for flavour, however – though the quantities and combinations are a closely-guarded secret.”

What strikes the visitor in this section of the production floor is the contrasting marriage of state-of-the-art technology – some of the newest in the country, says Marta, and with vertical storage added in 2011 to maximise space – and traditional techniques, such as hand-salting. “This is never going to be a totally mechanised process,” Marta adds, “human expertise and judgement will always be essential in determining quality and flavour.”

As the process continues, we see how technology is used to mimic nature, with various cooling rooms set at temperatures matching those of the seasons. Thus, once salted, the hams are stored for approximately one month at low temperatures that mimic the months of December and January: cold and dry. Next, in the pre-ageing process, they are stored for roughly three months at a temperature and in conditions that echo those you’d find outside in Tuscany during February and March: humid, cold and windy.

The curing process can take up to 20 months

Further stages mirror the climate between June and July, when the air is dry and warm. This is when the all-important smearing process takes place: pig fat is blended into a paste with salt, pepper (which acts as a natural anti-bacterial agent) and flour to create a natural seal around the meat. “Around 10 years ago, we switched from using wheat flour to rice flour within the paste, so that we could offer the customer a gluten-free product,” explains Marta, demonstrating that Viani was clearly ahead of the game regarding awareness of dietary requirements and potential allergens. Prosciutto also stands up to scrutiny when it comes to health scares surrounding cured meats – no nitrites are used in its production and Marta is keen to point out that the fat it contains is largely unsaturated.

During the final curing phase, the hams are left in a room where the temperature hovers between

Fabio Vieni smelling the horse bone spike to check the quality of the prosciutto

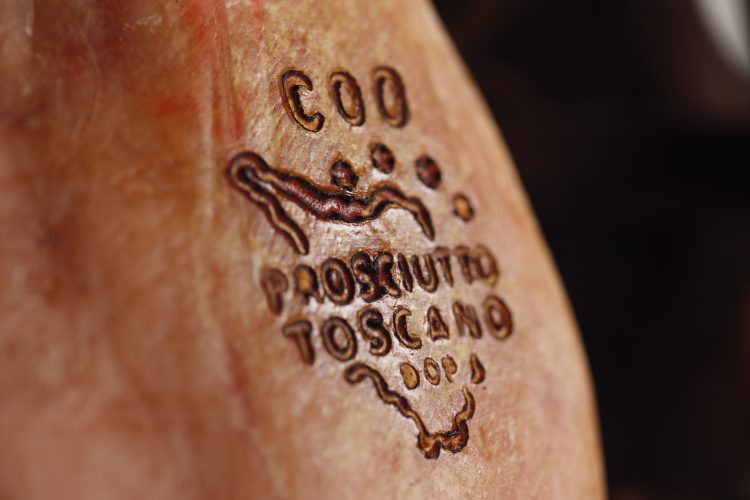

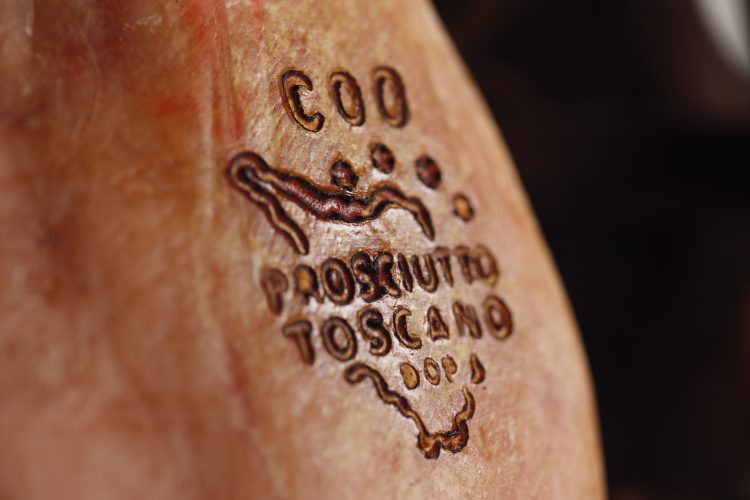

12‑14°C, before they are given a ‘spiking’. As the name suggests, a ‘spike’ or needle made from horse bone is inserted at different points within the meat. An experienced ‘nose’ within the team checks that the meat smells as it should, allowing for any potential possible defects to be spotted. Outside inspectors, too, carefully check the hams at intervals, to ensure safety and quality. Finally, once accepted as being up to the required standard, the meat is branded with the distinctive Prosciutto Toscano DOP mark.

By the time they are given a final taste and check, almost a year will have passed since the batch of porcine hind legs first entered the factory. “There is no room for speed here,” says Marta. “The curing process for some of our products – dissossare prosciutto, for instance, which is left on the bone – extends to as long as 16, sometimes even 20, months. The longer the cure, the better the taste.”

Promoting the culture and distinctive characteristics of the product

Away from the factory floor, we meet Marta’s brother, Fabio, who was elected President of the

prestigious Consorzio del Prosciutto Toscano in February 2019. He considers a primary part of his role as being to, “spread the culture and distinctive characteristics of our exceptional product; not just throughout Italy but around the world. That’s why Prosciutto Toscano DOP is participating in this year’s most important fairs: Summer Fancy Food in New York, the Anuga Food Fair in Cologne and Tutto Food in Milan – to get our message out and to allow buyers to find out more about us. Making it clear that we’re part of the EAT project, which emphasises all that DOP stands for and what makes us special, is very important, too.”

What are the key challenges facing Prosciutto Toscano?

Food fraud is an issue facing producers of all sizes throughout the world and being part of the DOP

The finished product

scheme, Fabio believes, is essential not only to ensuring the integrity of the product but in making food fraud harder to commit. “Ensuring our customers know what to look for – our branding and the DOP labelling – acts as a defence against counterfeiting and protection for the consumer and for those within the Consortium.” Fabio continued: “We’ve achieved so much since we launched the Tuscan Ham Consortium back in the 1990s, but there’s still great potential for growth. Our commitment will be to make consumers more aware of the significance of the link with the territory, the genuineness and traditions that PDOs guarantee, while never losing sight of our commitment to quality and food safety.” In European markets beyond Italy, the reality is that the Italian cured market is dominated by Parma ham. “Their brand awareness is so strong,” says Fabio, “they have an internationally-recognised name and they’re huge: they put out nine million products a year, while the Consorzio del Prosciutto Toscano puts out 400,000. With figures like that, we can’t compete on price.”

Nevertheless, some markets are receptive to the delights of Prosciutto Toscano, particularly Germany. Viani has also just started supplying to the US. Fabio said: “It’s very exciting for us as that market has huge potential. It’s demanding, too, though because of the specific US rules governing food production that we must adhere to. We need to use a totally different production line.”

Sampling the Viani DOP prosciutto, with its sweet mellow taste, may well be enough to persuade the consumer to broaden its horizons when it comes to the cured meats of Italy. As Marta explains: “While we cannot compete on price, we can compete on flavour, simply because we are so different. We offer a unique experience, with a taste that’s different from every other sort of ham. That’s why we say to buyers: visit us, try our product – we think it’s worth the extra.”

THE EUROPEAN ART OF TASTE PROJECT (EAT)

The EAT project is a three-year initiative, co‑funded by the European Union, to promote four areas of Italian food produced in the Tuscan Protected Denominations of Origin (PDO). These are Olio Chianti Classico DOP olive oil, Prosciutto Toscano DOP, Pecorino DOP cheese and Vino Chianti Classico DOCG (Designation of Origin Controlled and Guaranteed). The project aims to build awareness of these products and their characteristics at local, national and international level. Among the international target countries, the project leaders say that Germany and the UK are countries where there is little knowledge of PDOs and what they mean, “This is why the main goal of the programme is to expand and deepen the knowledge, to counter the advance of the products from the ‘new world’ while maintaining and conquering new market shares. In Italy, where there is more knowledge about PDO, the main objective is to increase the specialisation of the level of cognition and a small increase in market share.”

About the author

ANNA LAMBERT writes on food from both the consumer and producers’ perspectives, and her work has taken her around the world, from Germany and the Netherlands to Italy and the USA.

The rest of this content is restricted - login or subscribe free to access

Why subscribe? Join our growing community of thousands of industry professionals and gain access to:

- bi-monthly issues in print and/or digital format

- case studies, whitepapers, webinars and industry-leading content

- breaking news and features

- our extensive online archive of thousands of articles and years of past issues

- ...And it's all free!

Click here to Subscribe today Login here

Issue

Related topics

Equipment, Processing, Refrigeration and freezing, Robotics & automation, Technology & Innovation, Temperature control

Related organisations

Consorzio del Prosciutto Toscano (The Tuscan Ham Consortium), European Union, Salumificio Viani S.r.l.