Whey protein transformation: looking to solve waste in the dairy industry

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 15 October 2021 | Evita Achmadi | 2 comments

Global consumption of dairy products – and particularly milk products – is increasing, escalating the dairy industry’s production of waste. Here, food expert Evita Achmadi reflects on how we can turn by-product into value product.

According to USDA data, world milk consumption was approximately 190 million tons in 2020. India ranks top of this list, with 81 million tons of milk consumed last year – a figure which is expected to rise to around 83 million tons in 2021. The European Union (EU) comes next with 33.4 million tons, followed by the US with 21.2 million tons.1 This rise in milk consumption has encouraged growth in the dairy industry as well as the generation of more waste – the most significant of which is whey, given that this liquid by-product of cheese processing is already integrated into food products.

Whey is a by-product which has the potential to generate profit if properly treated and utilised, transforming it from waste to a value added product. However, the scale of increased dairy production (and subsequent dairy by-product) presents a challenge to the dairy industry. Global milk production reached nearly 906 million tons in 2020, up two percent from 2019, driven by output increases in all geographical regions, except in Africa where production remained stable. Milk volume increases were highest in Asia, followed by Europe, the Americas, Oceania, and Central America and the Caribbean.2

Solution to the waste issue

Whey is liquid by-product from milk coagulation in cheese processing. In the 19th century, there was an increase in cheese production which produced whey with biochemical oxygen demand (BOD) of 35-45 kgm-3 and chemical oxygen demand (COD) 60-70 kgm-3 which contributed to categorising whey as waste. Various efforts have been made to add value with whey using processing techniques to produce whey porridge, whey soup, whey tea and whey butter. In addition, whey is also dried using roller drying, spray drying and a combination of spray and rotary drum drying. However, the drying process is expensive has and the hygroscopic characteristics of the lactose content and denatured whey protein can be reduce solubility and functional properties.3 Thus, efficient and effective technology is needed to maintain the functional characteristics of whey protein when liquid whey is converted to whey protein. Such a technological solution would alleviate the increasing waste issue in the dairy industry and provide an essential dairy product for use not only as feed but also for food, nutraceutical and pharmaceutical applications.

Whey protein processing

Generally speaking, 10 litres of milk produces one kilogram of cheese and nine litres of whey. This whey can be sweet rennet whey and sour/acid whey. Sweet rennet whey is produced by coagulation using enzymes during milk processing and sour/acid whey results from precipitation in milk with acid conditions under pH 4.6. Whey protein is a globular protein consisting of 65 percent β lactoglobulin, 25 percent α lactalbumin, eight percent bovine serum albumin and immunoglobulin. In addition, some minor functional elements consist of lactoferine, lactoperoxide enzyme and glicomacropeptide. The functional character of whey protein depends on its protein content and technological improvements this century – such as recovery, separation and purification processes – facilitate a product with high nutritional and functional value.4

Determining the appropriate process modification necessitates identifying the microstructure you want to modify to produce the optimal nutrition and functionality. Modified whey protein can be used in food products, nutraceuticals and pharmaceuticals according to the characteristics and quality parameters needed.

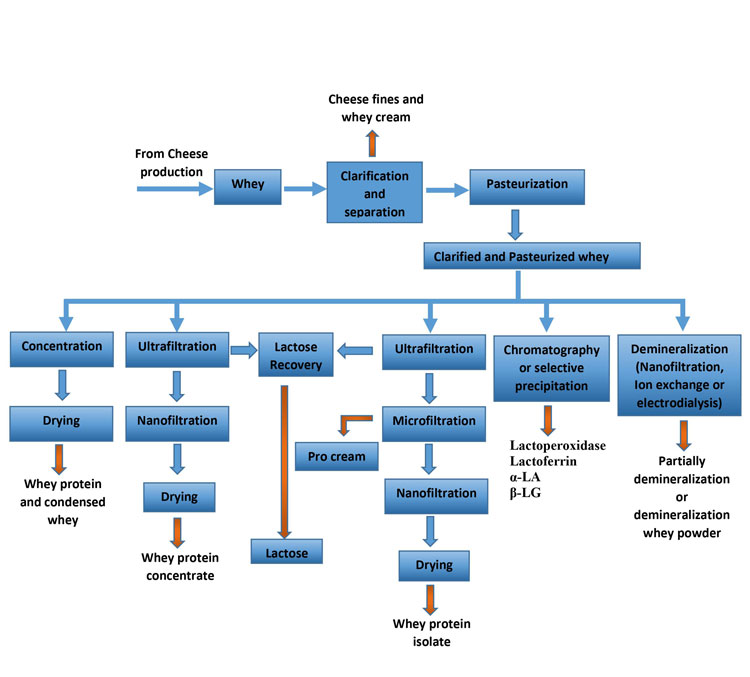

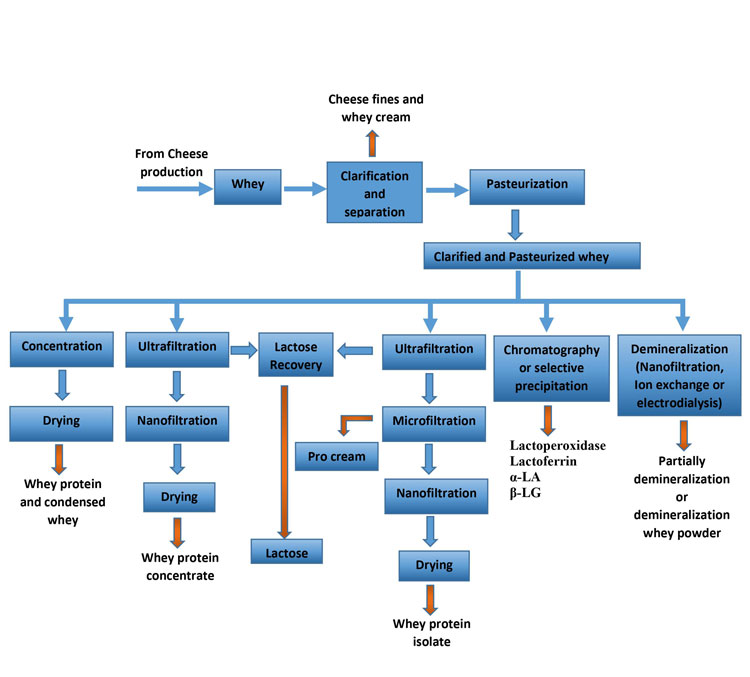

Modified whey protein is produced via clarification, separation and pasteurisation of liquid whey.

Figure 1: Whey protein production process

Each processing step is a key to optimising the functional characteristics of the whey protein by removing casein and fat from the liquid product. The next process involves separating lactose from the whey protein using membrane filtration; this technology recovers whey fraction in commercial products. This process can increase the whey protein content from 11 percent in sweet whey protein to 90 percent in whey protein isolate. Increasing whey protein content causes a decrease in the ash content by the demineralisation process. This removal of minerals is capable of producing whey protein with an ash content less than seven percent,3 making it suitable for use in baby food products as a functional ingredient. To maintain the functional properties of this protein, it is necessary to implement monitoring at every stage of the process. (see Figure 1).

Composition and functionality

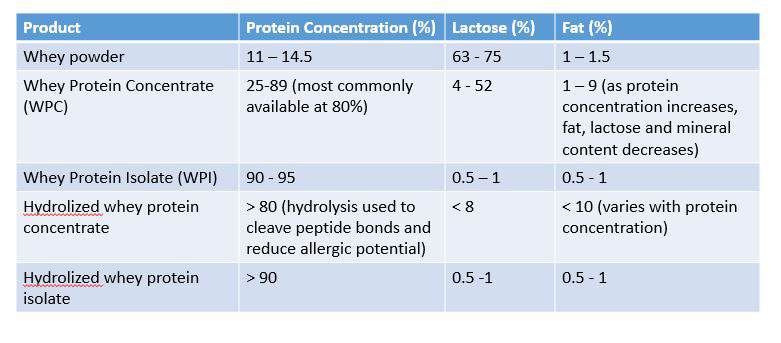

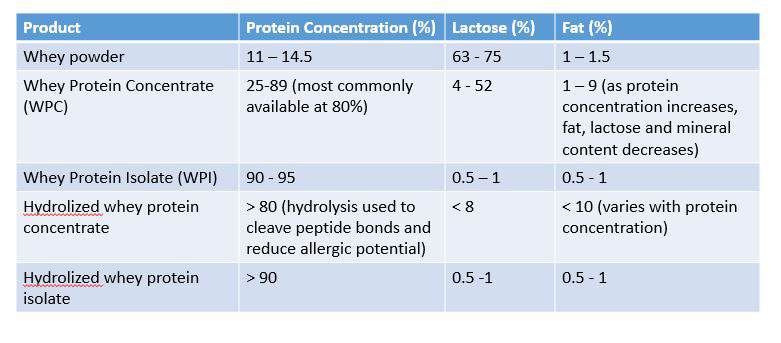

The selection of steps and processes applied will produce different properties and characteristics of protein fraction. Processing liquid whey will produce different types of whey protein, such as whey powder, whey protein concentrate (WPC), whey protein isolate (WPI), hydrolysed WPC and hydrolysed WPI. The composition of each whey protein product can be seen in Table 1.4

Table 1: Composition of whey protein product

WPC and WPI can be used as food additives for meat and dairy products due to their functional properties of holding water, gelling, emulsifying and foaming. β lactoglobulin (BLG) is a crucial component of these functional properties.

Whey protein concentrates and whey protein isolates have GRAS (generally recognised as safe) status from the US Food and Drug Administration (FDA) under regulation 21 CFR 184.1979c, subject to being manufactured from pasteurised milk under GMP.5

Health benefits of bioactive peptides

Whey protein is rich in bioactive peptides, which benefit the health of our cardiovascular and digestive systems, and enhance immunoregulation and the nervous system. Whey protein is also thought to possess health benefits such as helping to decrease blood pressure and cholesterol. Moreover, β lactoglobulin and α lactalbumin in whey protein have antimicrobial and immunomodulating properties. Another component – bovine serum albumin – is also a source of essential amino acids and inhibits oestrogen, which is related to breast cancer.6

Bioactive component peptides in whey protein are a natural bioactive substance which can have a positive influence on our health and prevent disease (nutraceutical). Based on these benefits of applying whey protein to food and nutraceuticals, it has potential for further development of functional properties and bioactive components. Optimising these functional properties and bioactive components will be challenging for industry and depend on enhancing key features, such as rheology and bioactivity, at each stage during processing, formulation and application.

References

- Global Dairy Industry and Trend Accessed Online 5 September 2021 at https://www.feedandadditive.com/global-dairy-industry-and-trend

- Dairy market review April 2021 Accessed Online 5 September 2021 at http:/www.fao.org.

- Mingruo G. 2019. Whey Protein Production, Chemistry, Functionality, and Applications. John Wiley & Sons Ltd. UK

- Dhillon GS. 2016. Protein Byproducts: Transformation from Environmental Burden Into Value Added Products. Academic Press. UK

- Phillips GO, dan Williams PA. 2011. Handbook of Food Proteins. Woodhead Publishing. Philadelphia.

- Onwulata C,I, Huth PJ. 2008. Whey Processing, Functionality and Health Benefits. Blackwell Publishing and the Institute of Food Technologists. USAAbout the author

About the author

Evita Achmadi holds a Master’s in Food Science and Technology from Indonesia. She has wide experience of handling project on research and development, quality and food safety. She is also a food consultant who is enthusiastic about bakery science and technology.

Related topics

Food Waste, Health & Nutrition, Ingredients, Processing, Proteins & alternative proteins, Research & development, Technology & Innovation

Your welcome Michael, feeling happy if its usefull for you

Evita, thank you for such an informative and well referenced article.