New methodological approach developed for food analysis

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 7 August 2019 | Rachael Harper (New Food Magazine) | No comments yet

Scientists have developed a new methodology that could simplify and accelerate the quality control of food.

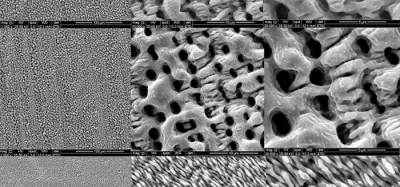

The simultaneous analysis of odorants and tastants could simplify and accelerate the quality control of food in the future (credit:: A. Dunkel/LSB/TUM)

Scientists at the Technical University of Munich (TUM) and the Leibniz-Institute for Food Systems Biology have developed a new methodological approach for the simultaneous analysis of odorants and tastants. It could simplify and accelerate the quality control of food in the future.

“We have now developed a new, innovative methodical approach that will enable us to examine food simultaneously for both odorants and tastants in a time-saving high-throughput process.

“It is based on an ultra-high performance liquid chromatography mass spectrometry (UHPLC-MS) method typically used for taste analysis,” said Thomas Hofmann, Director of the Leibniz-Institute for Food Systems Biology and Professor of Food Chemistry and Molecular Sensory Science at the TUM.

The new and time-saving feature of the developed approach is that volatile odorous substances can now also be analysed by means of an upstream enrichment or substance conversion step using this method, which is otherwise not used for aromatic substances.

“We have tested our new methodological approach using apple juice as an example. The results are very promising,” added Andreas Dunkel, Senior Scientist at the Leibniz-Institute of Food Systems Biology. Together with doctoral student Christoph Hofstetter from the TUM, he was substantially involved in the development of the new approach.

Andreas Dunkel and Christoph Hofstetter in their laboratory (credit: G. Olias/Leibniz-LSB/TUM).

The new method makes it possible for the first time to analyse a large number of samples in a very short time with regard to their taste and odor giving ingredients, the scientists said.

The researchers now hope to be able to further develop the method so that it can be used by food manufacturers in the future to quickly and easily monitor the flavor of food along the entire value chain and, if necessary, optimise it.

It could also be used to stop food fraud: “Using the identified flavor profiles, it would be possible to check the origin and quality label of the manufacturers and detect food fraud,” said Dunkel.

Related topics

Food Fraud, Processing, Quality analysis & quality control (QA/QC), Research & development, Sensory technology

Related organisations

Leibniz-Institute for Food Systems Biology, Technical University of Munich (TUM)