Givaudan and Bühler unveil Protein Innovation Centre

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 28 April 2021 | New Food Magazine | No comments yet

The new Protein Innovation Centre in Singapore will welcome start-ups and university researchers from across the region to develop plant-based food solutions.

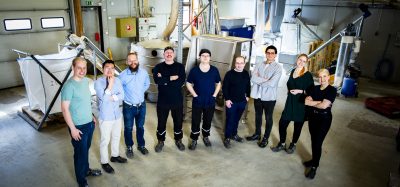

The Protein Innovation Centre will feature a "state of the art" product development kitchen Credit: Bühler and Givaudan

Food manufacturer Givaudan Taste & Wellbeing and food processing solutions provider Bühler have jointly announced the official opening of the APAC Protein Innovation Centre. Located at the Givaudan Woodlands site in Singapore, the Protein Innovation Centre will be jointly run and supported by experts from both companies and will be connected to a vast network of R&D Innovation Centres in Switzerland and key hubs across the region that enables agile plant-based product development on a global scale.

According to the two companies, the Protein Innovation Centre in Singapore will welcome food processing companies, start-ups and university researchers from across the Asia Pacific region keen to co-create plant-based food experiences that “do good and feel good.”

Outfitted with a pilot scale wet and dry extruder, a product development kitchen which has been described by the two as “state of the art”, storage facilities, meeting amenities and a viewing area where visitors may tour the 400sqm facility and view live demonstrations, the Innovation Centre is constructed with the end-to-end process of plant-based protein production in mind.

According to Givaudan and Bühler, businesses will also benefit from support throughout the co-creation process, from raw material selection to product development and research, to application, flavour science, extrusion and consumer testing. At the centre, customers will be able to develop products suitable for Asian culinary applications at scale. The facility can produce up to 40 kilogrammes of plant proteins an hour and features dry extrusion, as well as a newer wet extrusion technology that delivers a fibrous structure more akin to muscle, and higher protein content as compared with dry extruded products.

“We are proud to be part of a partnership that will contribute towards a sustainable food future for Singapore and the APAC region,” said Monila Kothari, APAC President, Givaudan Taste & Wellbeing.

“Through the Protein Innovation Centre, we aim to create an eco-system that supports start-ups and food businesses in an environment of co-creation. The centre will provide them access to the expertise, networks and technology required to create authentic plant-based protein alternatives that meet consumer needs and expectations.

“By bringing flavour solutions that are vegetarian, vegan, plant-based and natural, as well as technologies such as wet extrusion to Singapore and the region, we are helping to make plant-based foods more delicious, authentic and accessible to business and consumers. We are excited to open our Centre in Singapore, a country that is a hot bed for FoodTech innovation”

“Great tasting and sustainable protein alternatives are an important contributor to feeding 10 billion people sustainably by 2050,” said Ian Roberts, Chief Technology Officer at Bühler.

“The changes that need to happen to our protein value chains prior to that are so deep, they can only be achieved if the various partners of the food ecosystem start working together today. The Protein Innovation Centre that we open today with Givaudan at the core of Southeast Asia’s vibrant food ecosystem, is a step towards achieving our vision of a collaborative and sustainable future of food.

“The Protein Innovation Centre will not only enable the development of more plant-based protein products across Asia, it will also ensure delicious products can be scaled to the production volumes required to create a positive environmental impact on our food chains.”

Related topics

Flavours & colours, Processing, Product Development, Proteins & alternative proteins, Research & development, Technology & Innovation