Optimise your allergen control with colour coding

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 18 June 2019 | Deb Smith (Vikan) | No comments yet

Allergen management is vital in any food business, but optimal functioning requires it to be seamlessly integrated into a site’s overall food safety management system. Potential consequences of ignoring this, or getting it wrong, range from causing a consumer discomfort to causing their death. Deb Smith, global hygiene specialist, explains more.

Allergen control: why is it important?

Allergies of all kinds are on the increase. It is estimated that one in 50 children in the UK has a nut allergy. Peanut allergy cases have tripled in the last decade and hospital admissions related to allergic reactions have increased by 33 percent in the last five years. Every year in the UK there are around 10 deaths as a result of food allergies, with the under 25s being at greatest risk. Consequently, it is essential that all those involved with the production of food know what the allergens are, why they need to be controlled, and how this is best achieved.

Allergen control: legal and global food safety standard requirements

There are currently 14 allergens listed by the EU, and they are as follows:

|

● Milk ● Eggs ● Cereals containing gluten (wheat, rye and barley) ● Fish ● Crustaceans ● Molluscs ● Tree nuts |

● Soy (soya) ● Peanuts ● Sesame ● Lupin ● Mustard ● Celery ● Sulphur dioxide (sulphites). |

If your site produces foods that contains any of these allergens (allergenic foods) and/ or foods that don’t (non-allergenic foods), you have a legal responsibility to ensure that those that do are labelled properly, and that those that don’t are allergen free (or are labelled appropriately). In addition to the legal requirement for control of allergens, if you are working to the BRCv8 safety standard, this contains specific requirements regarding ‘Management of Allergens’.

Requirement 5.3:

‘The site shall have a system for the management of allergenic materials, which minimises the risk of allergen contamination of products and meets legal requirements for labelling in the country of sale.’

Section 5.3.8:

‘Use of validated cleaning methods and equipment that are identifiable and specified for use with allergenic material, and that are of single use or can be effectively cleaned after use.’

Allergen control: how can it be achieved?

Ideally, on a site that produces both foods that contain allergens and foods that don’t, production of foods that are allergenic would be carried out in a physically separated area, using dedicated equipment, facilities and personnel. This approach would minimise the risk of allergen cross-contamination to the non-allergenic products.

However, this situation is very rare and, more often, allergenic food production is carried out on a separate line that is spatially segregated from non-allergenic food production; or on the same line with a deep clean of the equipment between allergenic and non-allergenic food production.

In all cases, the use of colour coding can help to further minimise the risk of allergen cross-contamination and aid compliance with global food safety standards.

Use of equipment that is ‘…identifiable and specified for use with allergenic material’

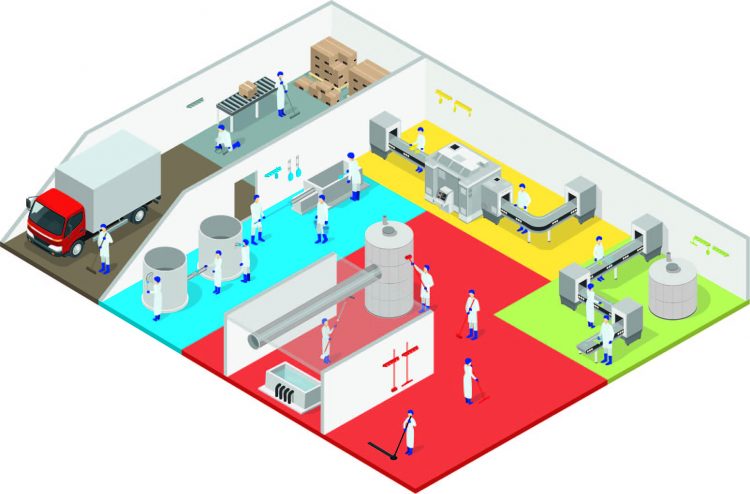

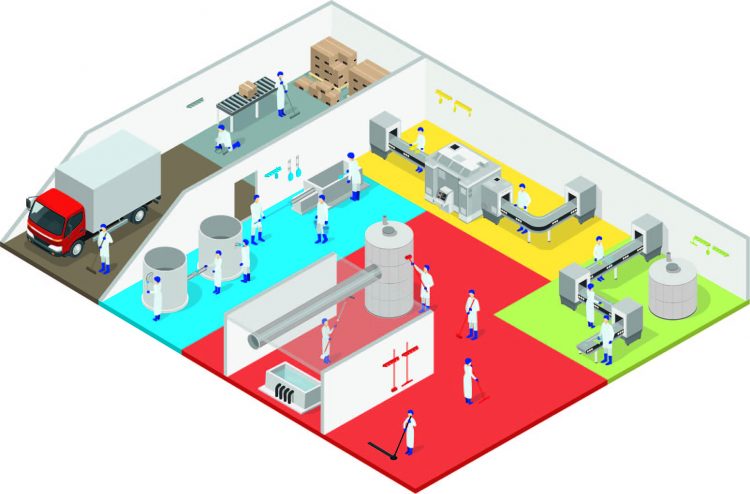

Use of colour-coded cleaning equipment and utensils provides a visual check that only equipment colour coded for use with that allergen is used. The more unusual and distinctive colours – such as orange, pink, purple and now lime – are often chosen for use with allergens. Additionally, equipment can be colour coded at a secondary level using coloured silicone rubber bands. These rubber bands can also be used to identify vacuum attachments used for different purposes. Segregation of allergen production areas by colour provides an easy visual check that only tools and utensils colour coded for use in that area are to be used; for example, the use of lime equipment only in the lime ‘allergen’ production area shown in Figure 1.

Figure 1: Segregation of allergen production areas by colour provides an easy visual check that only tools and utensils colour-coded for use in that area are to be used

To minimise the risk of cross-contamination further, cleaning tools and utensils used for allergens should be stored on colour-coded wall racks or shadow boards; for example, if lime-coloured equipment is used with the allergen sesame, they should be stored on a lime-coloured tool rack.

Equipment used for each different allergen should be stored on its own separate colour-coordinated rack or board, and no tool used for allergenic food production/cleaning should be stored on the same board as those used for non-allergenic food production/cleaning.

Use of equipment that ‘can be effectively cleaned after use’

Equipment that can be effectively cleaned after use incorporates hygienic design. Both the BRC and FSSC 22000 specify the requirement to use cleaning equipment and tools of hygienic design.

BRCv8

4.11.6. ‘cleaning equipment should be hygienically designed…’

FSSC 22000: ISO/TS 22002-1:2009

11.2 Cleaning and sanitising agents and tools: ‘Tools and equipment shall be of hygienic design…’

Good hygienic design principles have been specified by the European Hygienic Engineering Design Group (EHEDG).1 This document is available as a free download.2

They specify that equipment should:

- Have no sharp internal angles

- Have all areas accessible for easy cleaning and disinfection; ie, avoid deep recesses, nooks and crannies

- Be of one-piece construction, or quickly and easily dismantled/re-assembled

- Have a smooth surface finish

- Be made of appropriate materials; ie, nonabsorbent, food-contact compliant.

It is also important to clean equipment prior to first use. Un-wrapped, boxed or even bagged equipment may be contaminated with allergen residues from being handled during production, packing, transport and storage. Furthermore, all cleaning activities spread contamination, so the cleaning equipment and methods chosen to control allergens can play a key role in minimising cross-contamination:

- Choose cleaning equipment and methods that maximise contamination removal and minimise its spread

- Don’t clean, or at least minimise cleaning, during production

- Clean things as far away as possible from open product (spacial segregation)

- Clean in physically-segregated areas to protect product from splashes etc, (separate cleaning rooms/screens)

- Allow time for aerosols and particles generated by cleaning activities to settle before cleaning food contact surfaces

- Have dedicated allergen spill kits in the same colour as the allergen cleaning tools and utensils.

Further guidence on the use of colour coding for food safety, the selection of hygienically-designed brushware and the maintenance of cleaning equipment and utensils can be found on the Vikan website.3

TOP 10 TIPS FOR ALLERGEN CONTROL

1. Understand why it is important

2. Choose equipment of good hygienic design

3. Clean equipment before first use

4. Use colour-coded equipment for allergen use

5. Use colour-coded segregation of areas used for allergenic food production

6. Use methods and equipment that maximise cleaning and minimise spread of contamination

7. Store tools used for allergen cleaning separately and appropriately

8. Regularly inspect, clean and replace your cleaning tools

9. Have dedicated allergen spill kits

10. Train your staff in allergen control.

About the author

DEB SMITH has over 30 years of food safety/research training and experience. Prior to joining Vikan she worked for 16 years in DEFRAs Food Safety Division, and nine years as Food Hygiene Research Manager at Campden BRI. Deb holds qualifications in Applied Microbiology (HNC), Nutrition & Food Science (BSc(Hons)), Advanced Food Hygiene and HACCP, and is also a qualified FSSC 22000 Lead Auditor. She has authored/ co-authored numerous food safety/hygiene publications and regularly presents her research at National and International food safety events. Deb is an active Committee Member of EHEDG and IFST. She is also current Chair of the Micro MIG at Campden BRI, and sits on the Service Provision Technical Working Group of GFSI. At Vikan, Deb provides food safety and hygiene advice, training and support, both internally and to the food industry.

References

- EHEDG, 2018

- www.ehedg.org/guidelines/free-documents/

- www.vikan.com/uk/knowledge-centre/download-centre

Issue

Related topics

Allergens, Contaminants, Equipment, Food Safety, Free From, Ingredients, Processing, Regulation & Legislation

Related organisations

British Retail Consortium (BRC), European Hygienic Engineering & Design Group (EHEDG)