No artificial preservatives

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 11 November 2020 | Maxine Roman | No comments yet

Maxine Roman, Kraft Heinz, outlines the challenges and opportunities for removal of artificial preservatives in foods.

The role of scientists in the food industry is to develop food for consumers that is delicious, nutritious, and safe to eat. Quite possibly, the most important aspect of product development is ensuring that the product formula, processing and packaging work together to guarantee food safety.

Food antimicrobial preservatives may prevent the growth of microorganisms that decrease shelf life and threaten this safety. Without these ingredients, many of the packaged food products we find in the grocery store would spoil before reaching the supermarket shelves, or worse, could support the growth of pathogens that cause foodborne illness. Common food antimicrobial preservatives that the food industry has relied on for decades, such as sorbates, benzoates, and sodium and potassium nitrite/nitrate, are derived from synthetic means and, therefore, are known as artificial preservatives.

Modern consumers are increasingly demanding food and beverages free from artificial ingredients to fit into their lifestyles. This demand has given rise to growing interest in replacing traditional food antimicrobial preservatives with those that are derived from natural sources.

Kraft Heinz has been an industry leader in relaunching iconic brands in the US with no artificial preservatives. A few years ago, the company successfully renovated the entire Oscar Mayer hot dogs’ portfolio to remove sodium/potassium nitrate or nitrite. Similar renovations have been launched in the US for other iconic brands in the Kraft Heinz portfolio, including Philadelphia Cream Cheese and Kraft Singles.

Along the way, we have learned some important lessons. A successful reformulation to remove artificial preservatives involves a cross-functional combination of food safety, product development and ingredient research from the beginning.

The role of scientists in the food industry is to develop produce that is delicious, nutritious and safe to eat. Quite possibly, the most important aspect of product development is ensuring that the product formula, processing and packaging work together to guarantee food safety.

Food antimicrobial preservatives may prevent the growth of microorganisms that decrease shelf life and threaten this safety. Without these ingredients, many of the packaged food products we find in the grocery store would spoil before reaching the supermarket shelves, or worse, could support the growth of pathogens that cause foodborne illness. Common food antimicrobial preservatives that the food industry has relied on for decades, such as sorbates, benzoates, and sodium and potassium nitrite/nitrate, are derived from synthetic means and, therefore, are known as artificial preservatives.

Modern consumers are increasingly demanding food and beverages free from artificial ingredients to fit into their lifestyles. This demand has given rise to growing interest in replacing traditional food antimicrobial preservatives with those that are derived from natural sources.

Kraft Heinz has been an industry leader in relaunching iconic brands in the US with no artificial preservatives. A few years ago, the company successfully renovated the entire Oscar Mayer hot dogs’ portfolio to remove sodium/potassium nitrate or nitrite. Similar renovations have been launched in the US for other iconic brands in the Kraft Heinz portfolio, including Philadelphia Cream Cheese and Kraft Singles.

Along the way, we have learned some important lessons. A successful reformulation to remove artificial preservatives involves a cross-functional combination of food safety, product development and ingredient research from the beginning.

Food safety’s role is to identify the microorganisms of concern for a product and design testing protocols to ensure that any new formulas meet the action standards for food safety and quality. Testing protocols to determine the stability of a formula against microorganisms of concern are called ‘challenge tests’. Most food companies will test new formulas using a challenge test to determine if it is suitable to launch.

Product development’s role is to reformulate using new ingredients to replace artificial preservatives, while delivering on targets needed to launch a new formula. As many would expect, the key targets that arise with any brand renovation are maintaining the same great taste, achieving cost targets, and passing food safety requirements. This is where ingredient research can help.

Ingredient research’s role is to identify potential natural alternatives to current ingredients and determine product usage levels in specific applications needed for food safety and quality. Smaller companies may rely on the ingredient research at suppliers, whereas larger food companies may have dedicated internal resourcing to investigate potential ingredients solutions.

What the ingredient research team at Kraft Heinz has discovered is that there is not a silver bullet to replace sorbates, benzoates or sodium/potassium nitrite/nitrate. Every natural preservative has different levels of efficacy in different food matrices. The team that works on natural preservative ingredients research focuses on designing a robust research programme. Moreover, they are constantly improving approaches to identify natural preservatives that can help advance the pace of product development for renovation and innovation projects. As a result, Kraft Heinz has developed and improved upon methods for rapid and accurate screening of different formulas to enable removal of artificial preservatives.

Rapid testing for preservatives

Rapid screening of natural preservatives is an opportunity to streamline natural preservation product development, if careful consideration is taken into the design and execution. Most rapid screening found in academic literature involves testing the efficacy of different extracts in a growth media broth assay. While this may prove useful in early stage research to identify whether an extract has any antimicrobial activity, data collected from a broth assay cannot be used to confirm the potential of an antimicrobial in a food product.

In my experience, most extracts that have been proven to possess antimicrobial activity in a broth assay fail in challenge tests in food products. This is because of the influence of formula specifications such as moisture, fat, salt and pH on the growth of a microorganism, as well as the efficacy of an antimicrobial preservative.

It is also important to be cautious of using data from other food products to confirm the potential of an antimicrobial in the product of interest. Often, formula specifications of product can vary quite a bit, so it is crucial to design testing using the specifications of the food product of interest.

What our team has found to be the best approach in developing a rapid testing method for preservation formulas is to identify a model food that can be used to design testing protocols. Ideally, this model food should be representative of the food products of interest. For example, a common model used for the ready-to-eat meats category is turkey. Turkey is chosen because, typically, it is the base for the highest moisture and lowest salt formulas in the ready-to-eat meat category, which makes it more susceptible to pathogen growth than other meats, such as beef and pork. In addition, turkey has milder flavour, so it is a good candidate for evaluating the impact of antimicrobial preservatives on organoleptic properties.

The next step in designing a rapid testing method is to adjust formula specifications so that no preservative formula will fail within a reasonable timeframe to accelerate product development.

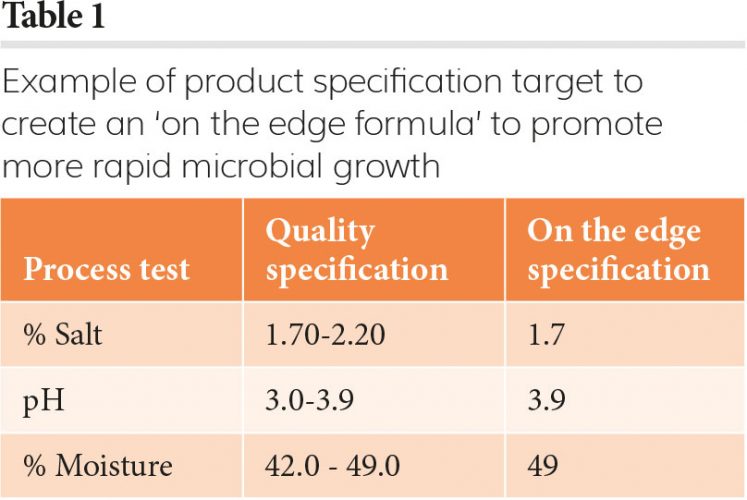

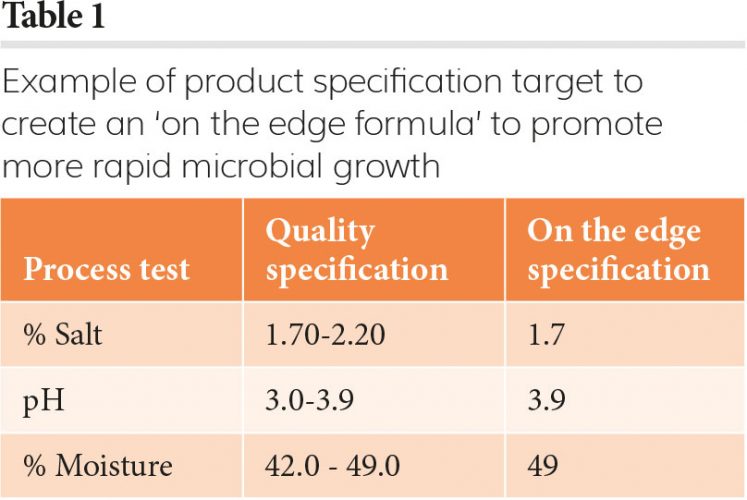

In most standard challenge tests for processed food, it can take weeks or even months for a no preservative product to fail. What are some approaches to promote product failure? First, it is best to create a formula that is ‘on the edge’ (see Table 1) of the range of quality acceptable for production. An on the edge formula to promote microbial growth typically has the highest moisture, lowest salt and highest pH.

Table 1: Example of product specification target to create an ‘on the edge formula’ to promote more rapid microbial growth

This formula can then be tested by screening against the microorganisms of interest. After testing the microbial stability of an on the edge formula, it may still be necessary to decrease the time for a no preservative formula to fail. In this case, a couple specifications that may be further adjusted are increasing formula moisture content and/or increasing the storage temperature to the optimum temperature for the microorganisms that are being tested. At this point, it may be worthwhile to test an artificial preservative formula to make sure that there is a control that is stable to adjusted formula and testing conditions.

Once the rapid screening method is designed and validated, it is time to identify lead ingredients to test. It is important to do your homework on ingredient offerings from a variety of suppliers. Usually, it is best to start by narrowing the scope to ingredients that are advertised to be efficacious against the microorganisms of interest. It may also prove useful to look at the ingredient composition and assess how the ingredient would partition in the food matrix. It is also important to understand what conditions (eg, pH, salt) make the ingredient more effective, so these can be adjusted when formulating into a food matrix.

A simple way to determine usage level for lead ingredients is to test for flavour impact of the ingredient and establish the threshold level before there is a significant change in flavour. Once lead ingredients and highest usage levels are identified, they can be tested in the rapid screening model. If an ingredient does not pass testing at the highest level that would be acceptable for flavour, then the ingredient can be easily deprioritised.

After screening ingredients in the rapid testing model and identifying the lead, there are additional tests that may be worth considering. Many natural preservatives are heat sensitive, so it may be useful to test ingredient stability at the highest process temperature. It may also be useful to rebalance and optimise the product specifications (eg, moisture, salt, pH) to improve the robustness of the overall formula. At several times during the development process, it is important to screen for flavour and rebalance.

Once the lead formulas have been identified through this rapid screening process, it is time to submit the formulas for full challenge testing. If the rapid screening is thoroughly designed and executed, the likelihood of passing challenge test is dramatically increased.

Natural preservation in foods is challenging to validate and execute; there is no magic remedy. Most new ingredients being promoted as natural preservatives are not fully vetted. The ingredient research approaches to rapid screening outlined here may offer an opportunity to create a streamlined process for developing natural preservative formulas, and deliver food to the consumer that is delicious, nutritious and safe to eat.

About the author

Maxine Roman currently leads natural preservation and biotechnology platforms for Kraft Heinz North America. She has experience managing research projects and developing pipeline strategies for ingredient, process and packaging technologies. Maxine received her PhD in Food Science from University of Massachusetts, Amherst.

Issue

Related topics

Clean Label, Food Safety, Free From, Ingredients, Lab techniques, Natural, New product development (NPD), Processing, Product Development, Rapid Detection, Research & development