GEA introduces unique continuous control system to its S-Tec spiral freezer range

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 6 August 2018 | GEA | No comments yet

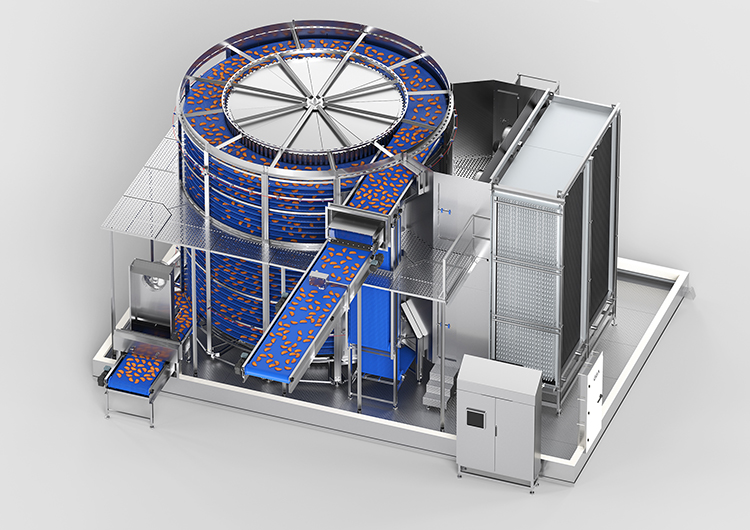

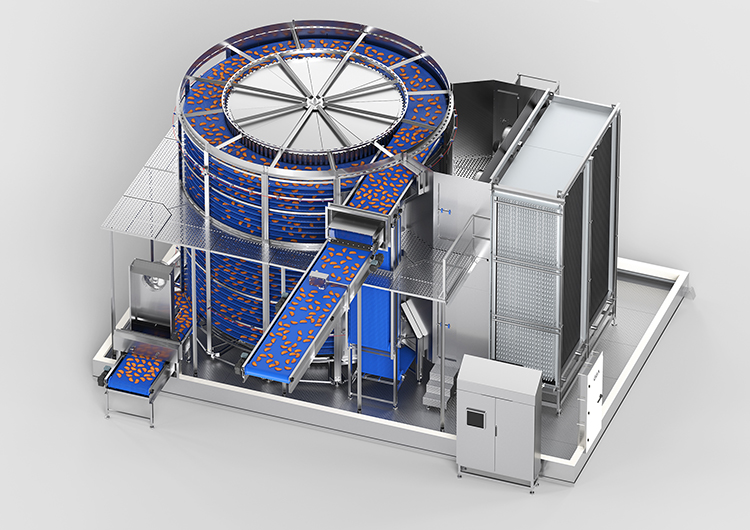

GEA has announced the addition of its unique control technology CALLIFREEZE® to its S-Tec range of spiral freezers for the food industry…

The new system ensures that all products are frozen precisely to the users’ requirements. CALLIFREEZE® takes its name from its ability to calibrate the freezer having controlled the level of frozenness of the products. This reduces power consumption, improves efficiency and helps manufacturers produce the finest quality frozen food.

The S-Tec was first introduced to the market in 2016 for poultry, meat, fish, ready meals, bakery and dairy applications that require capacities of up to 6,000 kg/hr. It was originally designed primarily for the European market and conforms to CE and PED regulations. It has now been selected by GEA for sale in Asia. The S-Tec has always been unique for its highly efficient airflow characteristics and hygienic design; the addition of CALLIFREEZE®, however, once again sets the S-Tec apart from its competition.

CALLIFREEZE®: a unique system of freezer control

CALLIFREEZE® is a new freezer control system that’s exclusive to GEA spiral freezers. It is able to calibrate the freezer parameters through the continuous measurement of the level of frozenness of the product at the freezer exit. GEA has enhanced its control system to continuously monitor the level of crystalised water in the products and adjust the retention time, air temperature and fan speed to achieve the precise level of freezing required, with the minimum of energy consumption.

Mathieu Nouhin, GEA’s Product Manager Freezing, said that there is no point in continuing to cool a product beyond 100 percent frozen but, until now, there has been no way of checking the level of frozenness of products as a continuous part of the process. “CALLIFREEZE® uses GEA’s unique sensing and control technology to measure the level of frozenness of every product in the spiral,” he said. “It then adjusts the machine to achieve perfect freezing in line with the customer’s requirements.” Mathieu also explained that for several applications, 80 percent level of frozenness at freezer discharge is acceptable with the product being ‘finish off’ in the cold store for energy savings purpose. “The S-Tec, with CALLIFREEZE®, can do this too,” he said. Results from one plant operating seven GEA freezers has showed a 10-15 percent production capacity increase with a reduction in energy consumption.

Even before the introduction of CALLIFREEZE® the S-Tec was already a market leader in the areas of hygienic design and operating efficiency:

Pure horizontal airflow for highly efficient freezing

Pure horizontal airflow is a unique feature of GEA spiral freezers. This provides a consistent airflow and temperature distribution across all products wherever they are in the spiral. This consistency, throughout the full height of the spiral, ensures that there is a very small temperature differential within the machine, reducing product dehydration, significantly improving the yield and keeping power usage to a minimum.

Hygienic design

The S-Tec uses a fully-welded construction for the whole of the product-contact belt area. This eliminates any dirt traps that would be created by a bolted structure and creates a perfect surface for cleaning. The S-Tec is also available with a fully-welded modular floor that does not require floor heating. Again, this removes dirt traps with structure elevated on pins welded to the floor for easy cleaning.

Flexible configuration

The S-Tec can be configured to meet each user’s needs with a choice of enclosure and floor types, single- or twin-drum configurations, and a selection of infeed/outfeed options – straight through, 90° turn, 180° turn, 270° turn and top-down or bottom-up operation. There is also a range of CIP (Cleaning in Place) options including the ultimate 6-Zone Recirculating CIP with full zone coverage and a recirculating system that captures and recycles water and cleaning agents after filtration, heating and new chemical dosing.

GEA servicing for the lowest Total Cost of Ownership (TCO)

GEA local service personnel are closely involved at the commissioning stage of all spiral freezers. This allows them to build a relationship with each customer and provide maintenance, spare parts and operational advice throughout the lifetime of the equipment. GEA service contracts are available allowing the GEA service team to offer optimised, year-round service to keep equipment in perfect condition for the lowest possible TCO.

For more information, click here.

Related topics

Equipment, Food Safety, Hygiene, Quality analysis & quality control (QA/QC), Refrigeration and freezing, Technology & Innovation, The consumer