Identifying, managing and reducing risk

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 16 December 2020 | Jaclyn Bowen | No comments yet

Jaclyn Bowen outlines three preventative control measures to consider in the age of consumer-driven food safety.

Consumer needs are a key driver in the development of new food products, so shouldn’t they also help drive the risk assessments food companies perform (by law) in order to stay in business?

Hazard Analysis and Critical Control Point (HACCP) is the internationally recognised system for identifying, managing and reducing the risk of safety hazards in food. For any quality assurance (QA) or food safety professional, one of the first steps of a HACCP programme is to identify the potential physical, chemical and biological hazards of a foodstuff, and then to determine how best to control them. When it comes to setting critical limits for these control points, most QA professionals would reach for the applicable regulatory limits (ie, those defined by regulatory bodies and/or by law). However, evolving consumer expectations are calling these long-standing practices into question, which have long been held as the best way to assess and define risk. It is time to incorporate consumer expectations of safety into the technical and regulatory evaluations of food safety risk.

The list of ingredients and chemicals to avoid is constantly changing.

Recent food exposes highlight the levels of glyphosate (the active ingredient in the pesticide ‘Round Up’ found in best-selling breakfast cereals, the levels of arsenic in best-selling bottled waters and the presence of bisphenol A (BPA) leaching from aluminum cans into finished products. The insidious challenge is that many of these products are compliant with respect to regulatory tolerances; but what about when it comes to the court of public opinion? Well, that’s a different story.

Court of law vs public opinion

From a macro perspective, the trend I am observing is a growing divide between the court of law and the court of public opinion on the definition of ‘safety’ when it comes to food products. The reason might be attributed to perceived corporate apathy coupled with Government inaction, which is contributing to a decline in consumer trust. Moreover, consumers worldwide are far more informed about foods than even a decade ago. So, what should you – as a concerned food manufacturer and brand – do?

In short, you should regard ‘regulatory tolerances’ as the overall compass and view ‘the evolving consumer need for safety’ as your True North. The following are three preventative controls, which can guide you:

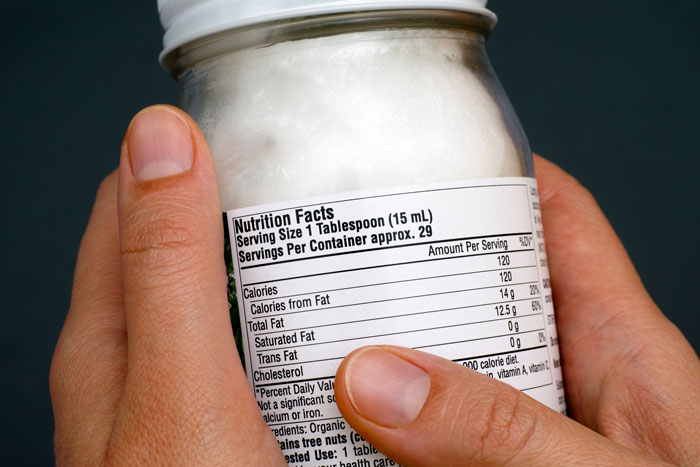

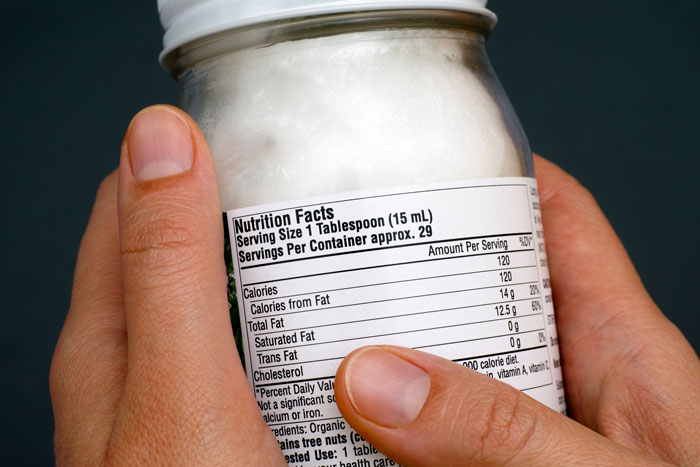

1. When was the last time you really looked at your product labels?

Free-from claims are on the rise. When it comes to ingredient avoidance, you see dairy-free and allergen-free claims. Related to packaging, you see bisphenol A (BPA)-free and phthalate-free. In consumer products, you frequently see paraben-free and sodium lauryl sulfate (SLS)-free. You even see these free-from commitments in some of the world’s largest private-label retail standards. Regarding consumer expectations, the list of ingredients and chemicals to avoid is constantly changing. Marketers are quick to adapt to these consumer trends, so it’s important that your quality assurance practices and their preventative controls also keep pace. When making a free-from claim, it’s important to ask what your definition of ‘free-from’ is. To an average consumer not familiar with the inner workings of

When did you last closely examine your product labels?

analytical chemistry instrumentation sensitivity and high-powered statistics, they may assume that free-from means ‘zero’. In the absence of a defined regulatory definition of the term, that may not be an unreasonable consumer expectation. Does free-from mean that the specified ingredient hasn’t been intentionally added as an ingredient into the finished product? Does it mean that maybe you didn’t add it to the finished product, but you cannot speak for your suppliers? Perhaps you define free-from as having test results that show ‘non-detect’ below some level, such as 40 parts per billion (ppb). But that does not mean ‘none’, does it? In all cases, the onus is on brands to be truthful and not misleading. Once you make a product claim, the responsibility falls on brands to stay true to that consumer promise. For a brand looking to foster consumer trust and transparency, its website can be a perfect place to provide thought leadership and educational context on product claims if all the information simply cannot fit on a product label. The next time you examine your HACCP programme, evaluate the role that your marketing claims play in product risk.

2. When it comes to product risk, sometimes the risk doesn’t come from the ingredients at all, it comes from the packaging

Stability and shelf-life testing are reliable markers that enable a brand to understand how its product ages over time and can help determine expiration When making a free-from claim, it is important to consider what your definition of ‘free-from’ is and best-by dates. Important components of shelf-life testing can include microbiological tests (eg, mould and bacteria), water and pH, rancidity, degradation of key vitamins and nutrients, and organoleptic qualities (such as colour, smell and taste). However, have you ever considered the way that your packaging ages during a shelf-life test? Chemical migration from packaging is a very real food safety hazard. Over the past decade, human exposure to BPA has received special attention, with some studies suggesting that BPA has links to endocrine disruption and infertility. It has been shown that exposure to BPA may occur through the consumption of beverages or foods that have been in contact with polycarbonate (PC) plastic containers or epoxy resins in food

Remember, when dealing with hazard analysis, it is no longer sufficient to just meet regulatory tolerances

packaging. For example, a BPA migration study1 was conducted using a variety of plastic containers, including PC baby bottles, non-PC baby bottles, baby bottle liners and reusable PC drinking bottles. Researchers used water and alcohol mixtures to simulate migration into different types of foods. The findings showed that residual BPA leaching from PC bottles increased with temperature and incubation time. By comparison, non-PC baby bottles and baby bottle liners showed only trace levels of BPA. Tests for leachable lead and cadmium were also conducted on glass baby bottles, since these represent a potential alternative to plastic bottles. No detectable lead or cadmium was found to leach from the glass. This study concluded that non-PC plastic baby bottles, baby bottle liners and glass baby bottles might be good alternatives for polycarbonate bottles given that plastic has been falling out of favour with consumers.

But perhaps you are thinking to yourself, “This doesn’t apply to me; I use BPA-Free packaging.” The Total Quality Management axiom of ‘trust but verify’ holds true here. Use testing to substantiate the packaging supplier’s promise. Also be mindful that bisphenols aren’t just used in product packaging. Bisphenols are industrial chemicals used in a variety of resins and plastics, including those used for industrial storage containers and other food contact surfaces. If you are making a BPA-free claim on product packaging, it is especially prudent to do more research. While the packaging being used may be entirely BPA-free, can you say the same for your entire manufacturing line and supply chain?

3. Identify the potential of high-risk ingredients

When designing a HACCP programme and potential high-risk ingredients, the mind of a quality assurance professional likely gravitates to low-acid, canned food, juice, seafood processing, and maybe sources of allergens. Given the increase in consumer concern over certain industrial and environmental contaminants, it makes sense to broaden that perspective. While there are plenty of high-risk ingredients, I am going to limit myself to discussing two of them.

High-risk ingredient one – cannabis-derived ingredients: Given the meteoric rise of the CBD industry, it’s no surprise that many corporate research and development departments are toying with new CBD-infused formulations. However, when it comes to CBD, it’s important to recognise one of the other main uses of hemp – as an effective tool in bioremediation. Phytoremediator plants like hemp help remove contaminants in soils. It has been used by military installations to remove radioactive elements from water, clean up toxic metals, pesticides, solvents, explosives, gasoline and even toxins from landfills. However, this means that the resulting hemp plant is a bio-accumulator of these heavy metals and chemical waste. Unless a brand voluntarily and proactively screens its cannabis-derived ingredients for heavy metals and pesticides, they could be unknowingly introducing these contaminants into their finished products.

High-risk ingredient two – grain-based ingredients: When considering potential risks from grain-based ingredients, it’s natural to consider the potential for gluten contamination within your gluten-free production facility or perhaps mycotoxin contamination. However, given the consumer concern over glyphosate, your grain-based ingredients might benefit from some form of glyphosate testing. When people talk of glyphosate, it is usually in the context of being used as a pesticide. However, did you know that it is also frequently used as a desiccant to hasten the crop’s dry down prior to harvest? While the ultimate regulatory fate of glyphosate is still unknown, consumers have spoken and expressed their sincere concern to such an extent that it has resulted in a successful glyphosate-residue free certification programme from an organisation known as The Detox Project. If you formulate with grain-containing ingredients, use routine monitoring and testing to minimise exposure and loss of consumer trust by steering clear of the contentious chemical.

The moral compass

When dealing with hazard analysis, it is no longer sufficient to just meet regulatory tolerances. Companies must factor the expectations of consumers into their analysis, too – even if this means tighter restrictions. In that regard, it is important that product labels are accurate and transparent to build consumer trust, that packaging is studied for potential adverse effects on the product, and that ingredients have enough due diligence conducted on them to understand the risks they might bring to the finished product.

Jaclyn Bowen MPH, MS

Jaclyn is the Executive Director of Clean Label Project and a food safety and quality systems engineer. Prior to coming to Clean Label Project, she spent 15 years at the World Health Organization Collaborating Centre, NSF International, working on the creation and enforcement of food safety and water quality standards and compliance systems.

Reference

- Kubwabo C, Kosarac I, Stewart B, Gauthier BR, Lalonde K, Lalonde PJ. Migration of bisphenol A from plastic baby bottles, baby bottle liners and reusable polycarbonate drinking bottles. Food Addit Contam Part A Chem Anal Control Expo Risk Assess. 2009 Jun;26(6):928-37. doi: 10.1080/02652030802706725. PMID: 19680968

Issue

Related topics

Allergens, Contaminants, Food Safety, Food Security, Free From, Labelling, Quality analysis & quality control (QA/QC)