Brewers stand to save as spent grain gets new lease on life

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 30 August 2017 | New Food | No comments yet

Researchers at Nanyang Technological University have developed a process that could see 85 per cent of a brewery’s waste repurposed.

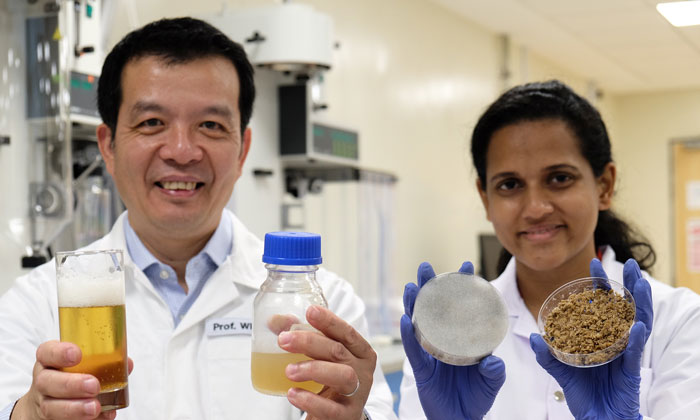

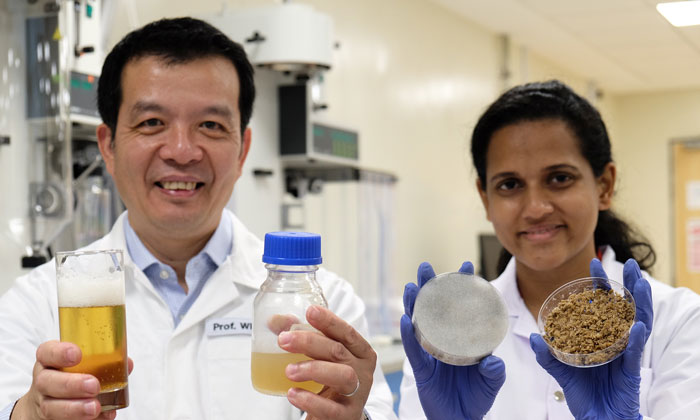

SAVE THE GRAIN: Prof William Chen (left) and PhD student Ms Sachindra Cooray

The Singaporean lab has been working on technology that turns spent grain into beer yeast.

Through its findings, published in AMB Express, brewers stand to save a considerable amount of money.

Similar commercial liquid nutrients are sold for US$30 per litre, but the team’s method of converting spent grain costs only a fraction of this.

Mr Mitchell Leow, Head of Corporate Affairs at APB Singapore, the brewer to whom the research grains were donated, said: “This research is a testament to how science and innovation enables communities to find novel ways to be more sustainable in their operations.

“Sustainability is a business priority, especially for a large-scale commercial brewery like APB Singapore. We take great efforts to reduce our waste footprint, through such circular processes that ensure materials like spent grain, glass bottles and even waste water are repurposed and not simply discarded.”

The weight of spent grain

Over 193 billion litres of beer are produced annually worldwide, which is enough to fill 77,000 Olympic-sized swimming pools.

Every five litres generates one kilogram of spent grain – or 38 million tonnes every year.

Often this is used for compost or animal feed, but Professor William Chen, Director of NTU’s Food Science and Technology Programme, together with his researcher Sachindra Cooray, has spent two years developing a process that could change that.

“We have developed a way to use food-grade microorganisms to convert the spent grains into basic nutrients that can be easily consumed by yeast,” Prof Chen explained.

“About 85 per cent of the waste in brewing beer can now be turned into a valuable resource, helping breweries to reduce waste and production cost while becoming more self-sustainable.”

Associate Professor Xu Rong, Interim Chair of the School of Chemical and Biomedical Engineering, said the burgeoning global population increasingly strains conventional food sources, so there is a need to innovate new foods and processes to alleviate the increasing demand:

“Discovering new uses for different types of natural food grade microbes in waste-to-nutrient technology is the latest breakthrough by NTU chemical and bioengineers, which can help to address the food security issues faced by the world presently.

“By upcycling waste to usable nutrients, conventional resources used to grow yeast can now be diverted into the production of wholesome foods.”

So how does it work…

When grains such as barley or hops are fermented by yeast, the grain’s sugars, protein and nutrients will be stripped, leaving behind plant fibres known as lignin.

While lignin is tough and generally unusable in food production, certain types of microorganisms are able to break lignin down into smaller, nutritious pieces.

These nutritious pieces can then be mashed and turned into a liquid, which are easily digestible by yeast.