What’s driving the need to register food grade lubricants and cleaning products?

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 20 August 2016 | Ashlee Breitner - NSF International | No comments yet

GFSI…FSMA…HACCP…FSCS…all of these used to be buzz words in the food industry but are no longer mere buzz words. They are now all key drivers behind ensuring chemical products, specifically lubricants and cleaners, are safe to use in the food processing environment. Over the past five to 10 years, product registrations for H1 (incidental contact lubricants) and A1 (general use cleaning products) used in food processing facilities have grown consistently, as food safety and risk mitigation have become increasingly important.

Food safety regulations are evolving all over the world and the US Food Safety Modernization Act (FSMA) is now ingrained into the minds of food processors everywhere. While FSMA is a regulation enacted by the US Food and Drug Administration (FDA), it will have global implications for food suppliers. According to the USDA’s Foreign Agricultural Service’s report on processed food imports, the European Union collectively exported more than $18bn (USD) in processed food to the United States in 2014. Now that FSMA’s Preventive Controls for Human Food rule is final with compliance dates for some businesses starting in September of 2016, covered facilities must establish and implement a food safety system that includes an analysis of hazards and risk-based preventive controls. Preventive controls are measures required to ensure that hazards will be minimised or prevented, and can include process, food allergen, and sanitation controls, as well as supply-chain controls and recall plans. In practicality, this translates into increased scrutiny on hygiene and processing plant controls for food producers making products intended to ship to the US market; and lubricant and cleaning product registration forms part of that.

HACCP

As today’s food manufacturers realise the importance of identifying contamination risks, the correct use of third party registered products for the different applications in facilities provides a reliable prerequisite approach to complement a HACCP (Hazard analysis and critical control point) plan. The US Department of Agriculture (USDA) formerly reviewed and authorised non-food compounds or chemical products acceptable for use in food processing and handling facilities. In 1999 NSF International, a not-for-profit public health organisation, took over the responsibility of evaluating food grade lubricants and other food processing substances such as cleaners. Working with the USDA, NSF captured all previous review requirements and launched a third-party registration and listing programme for these products, represented by category codes developed and based on the particular intended end use of the product. Today this registration has a global reach with products produced in over 50 countries and continues to grow as food safety becomes more and more of a concern to consumers, producers and regulators.

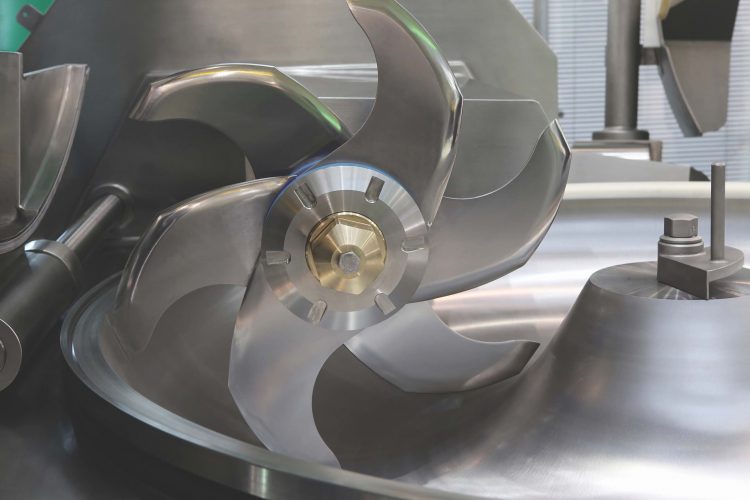

Contact of the food and lubricant is possible due to the proximity of the machinery to the food production line.

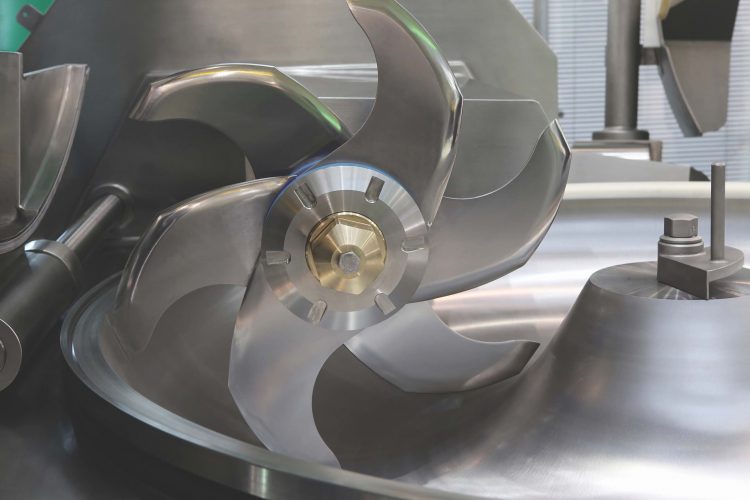

While HACCP plans tend to focus on the handling of the actual ingredients and products, manufacturers now also need to consider seemingly peripheral aspects, such as the lubricant on a chain or a cleaner on a cutting surface. What may seem to be a minor issue could have a massive impact on a product, a company’s reputation and public health. The well-recognised benefit of using food grade or incidental contact lubricants is the effect of limiting the introduction of potentially hazardous chemical agents to food products that could adulterate them and cause harm to human health, if ingested. Most processors understand that food grade lubricants are a logical and practical solution to addressing critical control points, or points in their operations where contact of the food and lubricant is possible due to exposed lubrication points, or proximity of the machinery to the food production line.

What they don’t understand, though, is that not all third party registered lubricants are created equal. Product registration category codes have been developed to ensure that all products intended for specific applications are reviewed equally against the necessary criteria for that product’s intended end-use. The criteria are often based on regulations in place for a particular product, ingredient or material type and also take into consideration key aspects of the process used to manufacture the product. While being applied in a production process, something as simple as a letter grading may not seem particularly important, yet the impact of using the incorrect product could create a significant potential risk of food contamination. Products with the H1 category designation are acceptable as an incidental contact lubricant in and around food processing areas. One number different can mean something very different though! A product with the H2 designation is a product that is acceptable as a lubricant where there is NO possibility of food contact – NOT even incidental contact.

Registration aids GFSI compliance

The use of third party registered H1 lubricants, specifically as part of a strong HACCP plan that looks at both the chemical and physical risks associated with food processing, is an important and critical step toward completing certification to the Global Food Safety Initiative (GFSI) benchmarked standards. In addition, the use of registered products is important, not just at the food manufacturer level, but prior to that at the manufacturer’s ingredient suppliers. Using registered products and ingredients is a critical link in the supply chain and one that can influence the success of achieving certification to a GFSI benchmarked standard.

Allergen control

What is less obvious, but equally important, is to recognise that food grade lubricants and third party registered cleaning products are helping the food industry address some of its most current and pressing food safety concerns. Today’s food processors are focused on many issues affecting consumers worldwide including: allergen control, microbial contamination, traceability, smart packaging compatibility, and work force management.

An increasingly important factor in protecting consumers’ health and safety is allergen control. The trickle-down effect of the focus on this allergen protection falls down the supply chain to that of the chemical producers. One of the recognised standards under the Global Food Safety Initiative is the BRC Issue 7 Standard. In 2015 this standard was revised specifically citing “Materials used for equipment and plant maintenance that pose a risk by direct or indirect contact with raw materials, intermediate and finished products, such as lubricating oil, shall be food grade and of a known allergen status”.

Manufacturers need to consider the lubricant used on a chain or a cleaner on a cutting surface.

According to the United States Department of Agriculture (USDA), a 2014 summary of food recalls for agricultural products cited more than 40 individual product recalls due to undeclared allergens. The USDA also reports a consistent trend of increasing recalls year-on-year due to allergen mislabelling or contamination, with the highest number yet predicted for 2015. The good news is that food grade lubricants (whether H1 Registered or ISO 21469 Certified- Hygiene requirements for safety of machinery; Lubricants with incidental product contact) and ‘A’ category registered cleaners place an emphasis on careful ingredient traceability and control. This means a food grade lubricant supplier should be able to confirm the presence or absence of the most common allergenic substances, eliminating the lubricant or cleaner as a potential source of allergen contamination.

Resources

There are a few critical recommendations for any food processor looking to switch to registered chemicals or expand use within their current facility operations. Here are a few key points to bear in mind:

- Most reputable suppliers have products backed by independent registrations, such as A1 or H1 Registration or ISO 21469 Certification by NSF International (nsfwhitebook.org)

- Be certain your supplier understands the unique nature of your operations

- Work with a chemical manufacturer who understands food safety principles and is knowledgeable about the risks and controls inherent to food production. Invest in a partnership, not just a product

- Ensure that those using the chemicals in the plant understand that registered products are not one-size-fits-all in terms of product safety (verify the category the product is registered to).

Specifically for lubricants, in March 2016 a position paper for Food Grade Lubricants was published by the European Lubricating Grease Institute and the National Lubricating Grease Institute. Formed by the food grade working groups of these institutes, the position paper’s purpose is to give food processors using lubricants a quick reference guide for terminology and typically asked questions in relation to the use of food grade lubricants. This position paper is published at www.elgi.org

Summary

Whether it’s compliance for FSMA, HACCP, or GFSI for processors looking to improve their maintenance plan, using third party registered food grade lubricants or registered cleaning products is an excellent and straightforward option. The market for registered chemicals is growing fast, both due to the proliferation of new product development and, more importantly, because of the trickle-down effect of these regulations and enforcement policies that are now in place in the food processing industry. Understanding what product categories are, and the value of sourcing and appropriately applying registered products is a critical element of a production facility’s quality plan and should be considered very closely by those responsible.

About the author

Issue

Related topics

Equipment, Food Grade Lubricants, Food Safety, Processing, Regulation & Legislation

Related organisations

NSF International, US Department of Agriculture (USDA), US Food and Drug Administration (FDA)