Researchers turn food waste into biodegradable plastic in breakthrough study

Posted: 18 July 2025 | Ben Cornwell | No comments yet

Scientists in New York have developed a low-cost, scalable method to transform discarded food into eco-friendly bioplastics using bacteria.

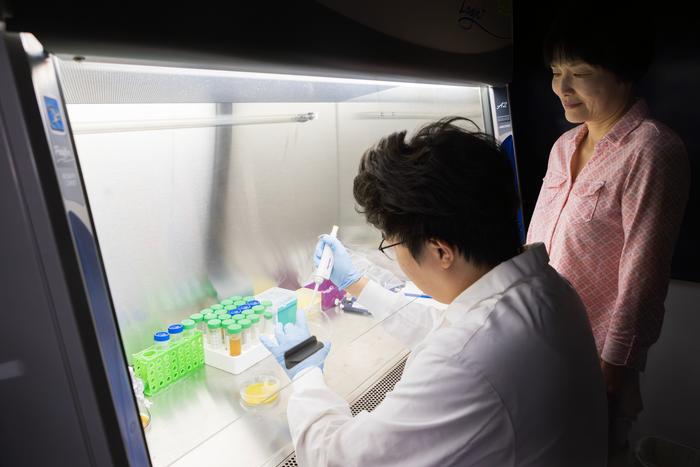

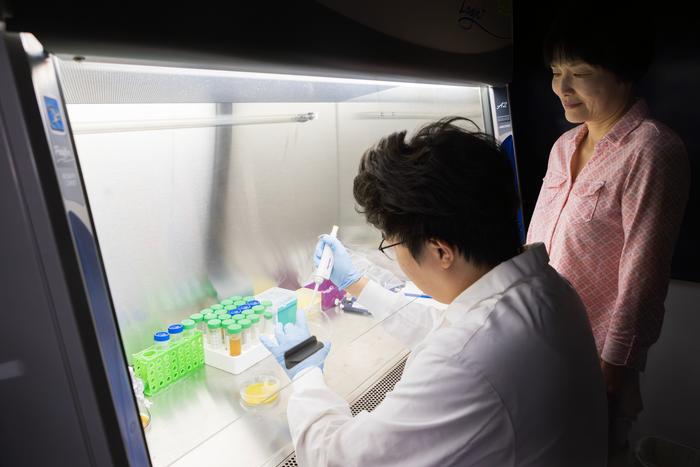

Binghamton PhD student Tianzheng Liu, left, and Department of Biomedical Engineering Professor Sha Jin have developed a method to turn food waste into biodegradable plastic. Credit: Binghamton University, State University of New York

A research team at Binghamton University, State University of New York (SUNY) has developed a pioneering process that transforms food waste into biodegradable plastic. The innovation addresses two major environmental issues: plastic pollution and the large-scale disposal of food waste.

Published in Bioresource Technology, the study outlines a cost-effective method that uses food waste fermented into lactic acid and processed by plastic-producing bacteria. The project was led by PhD candidate Tianzheng Liu, with academic support from Professors Sha Jin and Kaiming Ye.

Jin’s interest in the issue began in 2022, when she received a grant from New York State to explore new uses for discarded or leftover food.

She explained:

We can utilise food waste as a resource to convert into so many industrial products, and biodegradable polymer is just one of them.

We’re aiming not only to valorise food waste but also reduce the manufacturing cost of this eco-friendly polymer.”

The goal of the study is to develop a zero-waste recycling system that significantly cuts greenhouse gas emissions by converting food waste into biodegradable plastic. Existing biodegradable plastic production is costly because it depends on refined sugar substrates and pure microbial cultures, limiting economic viability.

Jin’s project focuses on eliminating food waste by turning it into sustainable, low-cost raw materials suitable for various sectors, including medical and packaging industries. Her laboratory plans to recycle discarded food sourced from restaurants, homes and supermarkets, using fermentation to produce the biodegradable plastic.

The Binghamton team used Cupriavidus necator bacteria, feeding them lactic acid fermented from food waste as a carbon source, and ammonium sulphate as a nitrogen source. The bacteria then produced polyhydroxyalkanoate (PHA), a biodegradable plastic, as a way to store energy and carbon.

Approximately 90 percent of the PHA generated can be harvested and moulded into packaging and other biodegradable products. However, the journey was not without its challenges. Liu commented:

The bioconversion of food waste into organic acids was a relatively easy one. Cultivation of the plastic-producing bacteria was hard. At every move, I felt like something was not what I expected.”

Inspiration for the study

The team sourced food waste from Sodexo and Binghamton University Dining Services. Jin explained how institutional policy inspired the idea:

I talked to the sustainable officer at the University and learned that SUNY doesn’t allow landfill food waste — that’s the policy. Each campus is expected to solve the problem. At Binghamton, the dining halls give wasted food to farmers to feed their livestock. I thought maybe we could try to directly convert that food waste into biodegradable plastics. There was little information from research publications about the feasibility of this idea, so we felt like maybe that was the gap we could work on.”

Researchers also examined whether the process could handle the variety and inconsistency typical of food waste. Their findings showed that the method remains stable for up to one week of waste storage, offering practical benefits for industrial collection. Jin added:

We discovered that the process is very robust, as long as we have different types of food mixed in at the same ratio. We control the temperature and the pH during fermentation, and those conditions encourage organic acid-producing bacteria to grow.”

The leftover solids from the fermentation process are now being developed into an organic fertiliser, offering an alternative to synthetic chemical options.

Looking ahead, the team hopes to scale up the process. Jin is currently seeking further funding or collaboration with industry partners to move towards commercial production of biodegradable plastics made from food waste.

Related topics

Environment, Food Waste, Packaging & Labelling, Research & development, Sustainability, Technology & Innovation