High energy whisky (with water) – how membranes can provide sustainable water systems and energy recovery for distilleries

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 26 April 2016 | New Food | 2 comments

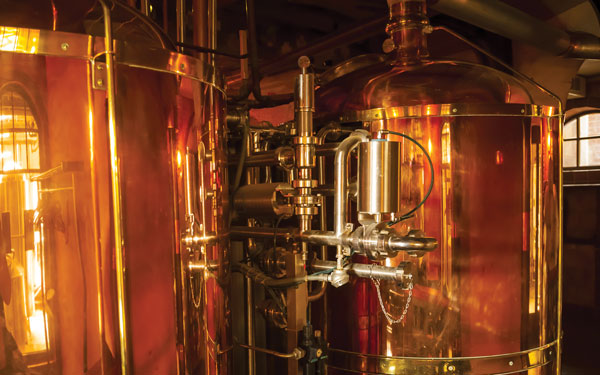

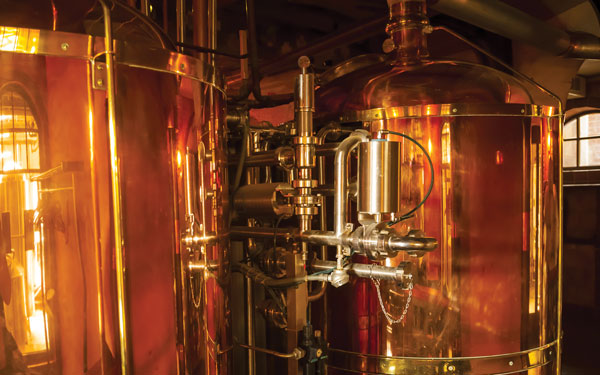

Scotch whisky production is one of the industry’s most conservative sectors but it is increasingly looking to new technologies to improve sustainability, minimise costs and maximise operational benefits. Three key areas of consideration are the reduction of waste; overall energy use; and water consumption – to meet the Federation House Commitment to reduce water consumption by 20% by 2020.

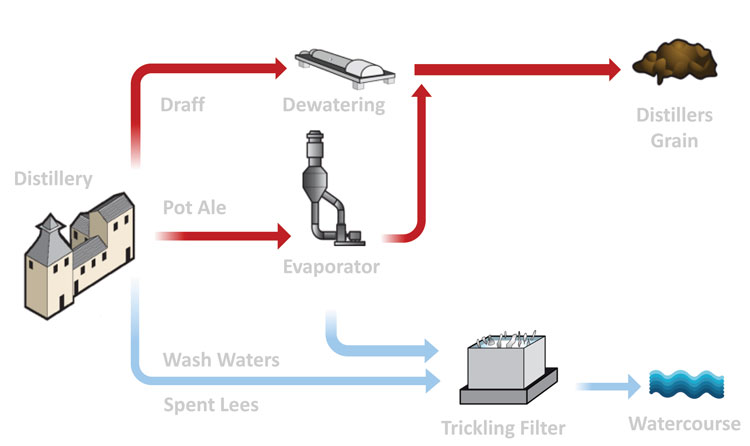

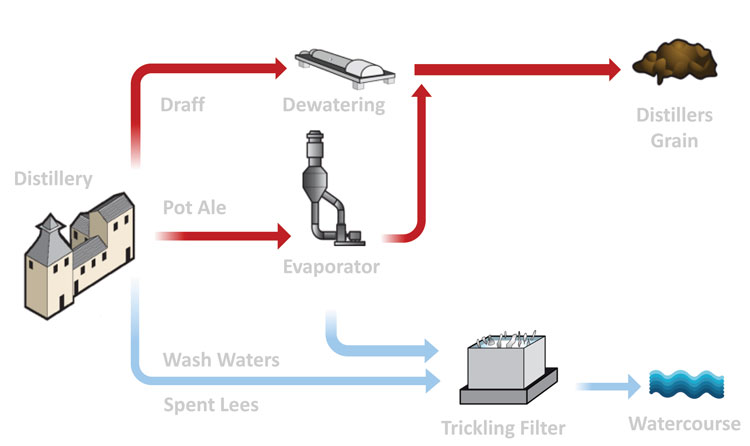

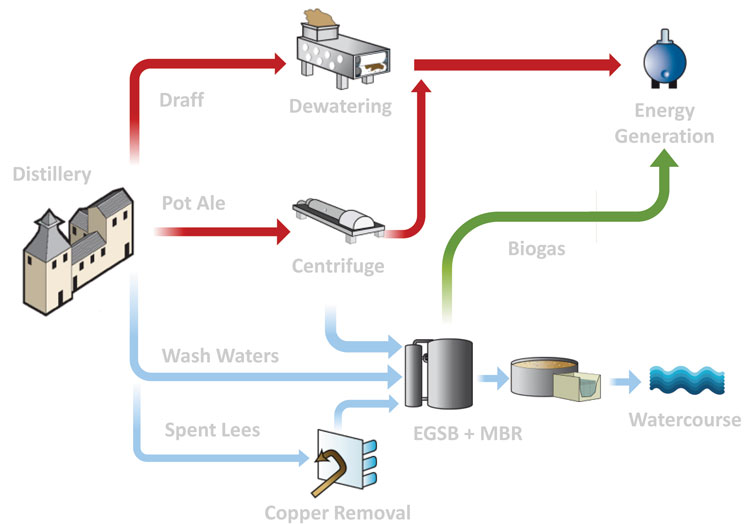

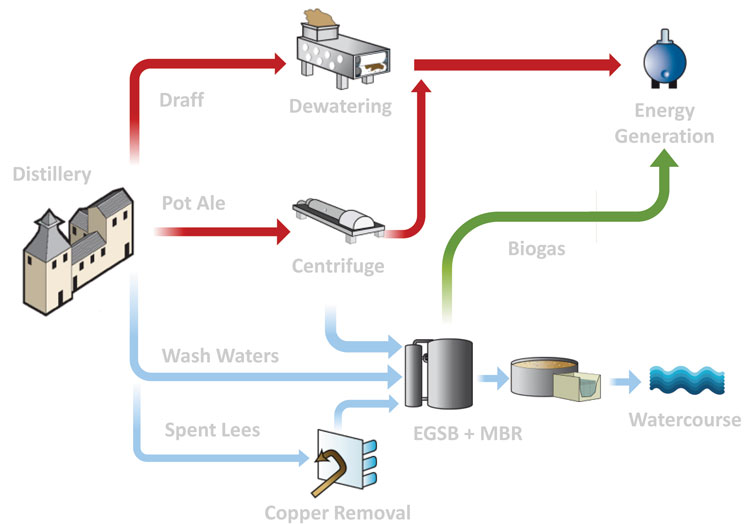

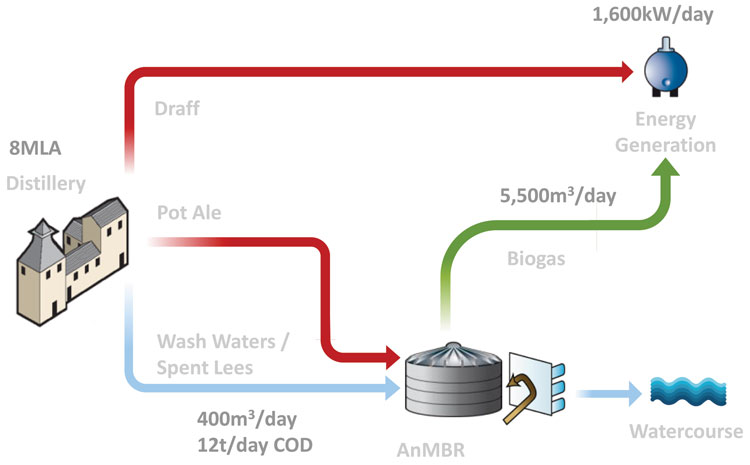

The traditional approach to dealing with distillery waste (Figure 1, page 67) is to dewater the draff (spent grains from fermentation) and blend it with evaporated pot ale (the residue from initial distillation) to make a by-product (Distiller’s Grain) for sale as cattle feed. Spent lees (the residue from the second distillation), wash waters and other aqueous wastes are treated, typically by a biological trickling filter, prior to discharge to sewer or a watercourse. However, a number of factors are combining to alter this approach.

Figure 1

Firstly, the increasing cost of energy makes Pot Ale evaporation expensive whilst the fluctuating price of cattle feed brings the value of Distiller’s Grain into question. Secondly, many of the trickling filters currently in service are 50 years old and efficiency is poor. The tightening of consent limits for the discharge of wastewater to watercourses requires additional treatment, whilst the adoption of Mogden formula charging based on COD for sewer disposal is making this route more expensive. Thirdly, the rising cost of mains water, where this is used, impacts on operating costs. The latest process developments can provide sustainable solutions combining bio-energy production and water recycling.

Membrane bioreactors have a good track record in distillery wastewater treatment in combination with anaerobic treatment to recover energy, as Figure 2 shows.

Figure 2

Here the pot ale and draff are separated from the spent lees and wash waters, mixed with dust and culms and dewatered, dried and burned in a specially designed duel fuel (biomass and biogas) fired boiler to produce steam and electrical energy, which is used on site. The spent lees, as common in distilleries, is contaminated with a low level of copper picked up from the still. In order to ensure that the copper consent is met, this spent lees is treated by an ion exchange plant to remove the copper prior to mixing with the liquors from the dewatering process. The combined liquors are treated in a Biothane expanded granular suspended bed (EGSB) high rate anaerobic reactor. This uses a granular anaerobic biomass to convert a high proportion of carbonaceous COD into methane-rich biogas, which is used as an additional fuel for the boiler. Following the anaerobic treatment stage, the aqueous stream is passed to a membrane bioreactor (MBR). This is an aerobic process in which aerobic bacteria remove most of the residual COD and also convert ammonia into nitrate (nitrification). It also incorporates an anoxic denitrification stage to reduce total nitrogen. Meeting the SEPA discharge consent necessitates membrane filtration as a final process stage, and this produces a high quality effluent that can be fed directly to a reverse osmosis unit to be reused as boiler make-up water. Excess biomass generated in the biological treatment processes is mixed with the draff prior to dewatering to provide additional biofuel for the boiler. The system provides 98% of the steam and 80% of electrical power used at the distillery, reducing annual carbon dioxide emissions at the site by approximately 56,000 tonnes.

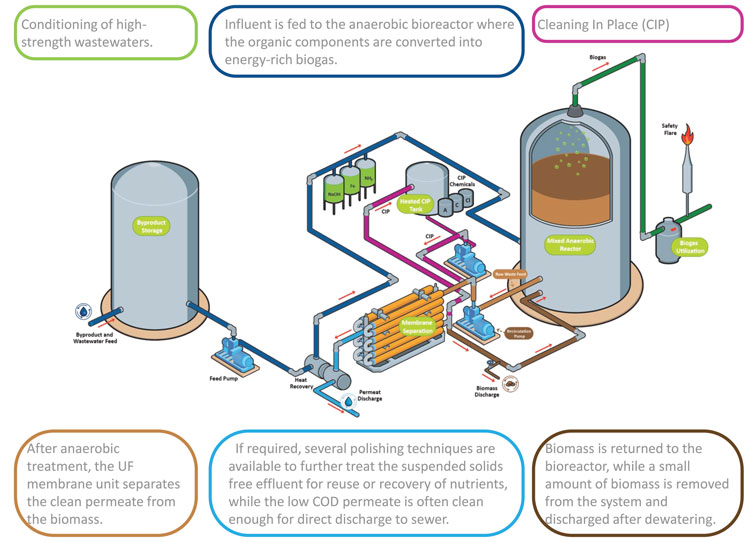

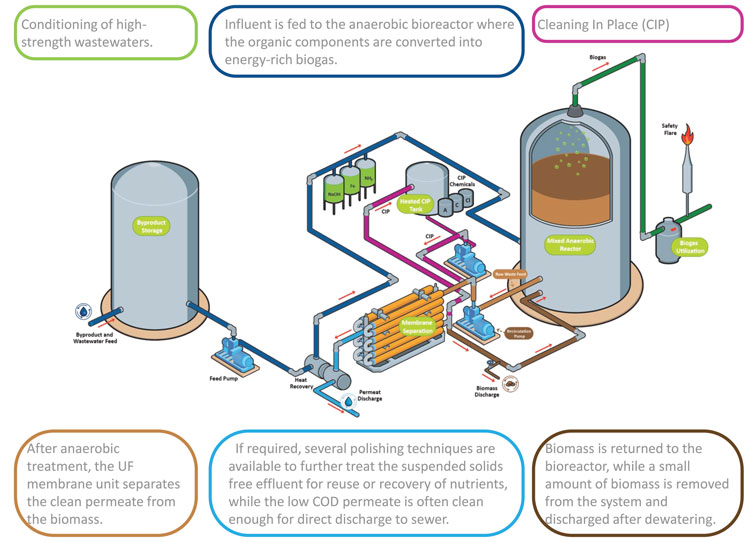

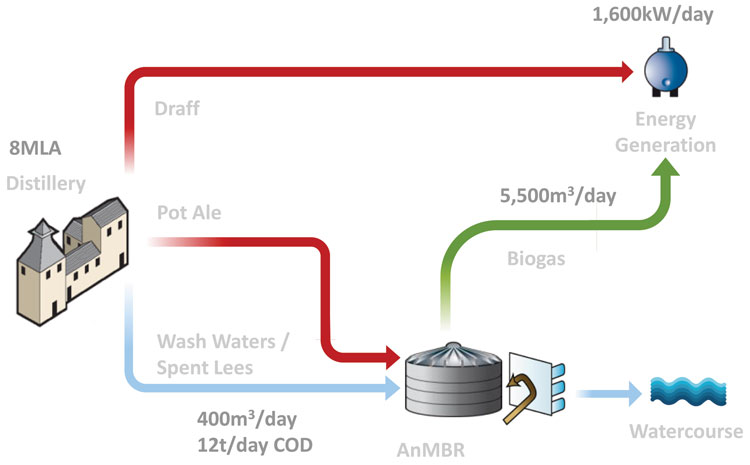

So successful has this total bio-energy approach been that a novel solution that combines the advantages of anaerobic digestion and membrane bioreactor (MBR) technologies has been developed in a compact anaerobic membrane bioreactor (AnMBR). The system (Figure 3) consists of a high efficiency anaerobic bioreactor followed by a membrane ultrafiltration system.

Figure 3

Wastewater is fed to the anaerobic bioreactor where the organic components are converted into biogas, which usually more than satisfies the process energy requirements with surplus being available as a renewable energy fuel for boilers or CHP plants. The effluent from the anaerobic reactor is pumped to the ultrafiltration modules, where permeate is separated and biomass is returned to the bioreactor. The permeate has negligible suspended solids concentration and can potentially be fed directly to a reverse osmosis plant allowing approximately 70% or more of the wastewater to be recovered at a quality at least as good as that of softened mains water. This water can be used for applications where potable water is not mandatory, such as boiler or cooling tower make-up and CIP. The ultrafiltration membrane retains sludge in the system, minimising surplus sludge production and disposal costs. It also retains high molecular weight COD, which is often difficult to biodegrade in conventional anaerobic reactors, for a sufficiently long period that most of it is broken down. This not only reduces the COD but enhances biogas production. By combining two steps into one, the process typically reduces the influent COD by more than 99% and this usually means that no additional expensive aerobic post-treatment is necessary.

Treating high strength wastewater by anaerobic membrane bioreactors produces a treated effluent that is usually low enough in COD to be discharged directly to surface water and with low enough turbidity to be fed directly to reverse osmosis (as proven on several full-scale industrial plants). Biogas production provides a sustainable source of renewable energy and the possibility of nutrient recovery offers a potentially saleable additional by-product. There are now about a dozen AnMBR plants in operation around the world and these have demonstrated that the combination of reduced effluent discharge costs, low operating costs, energy recovery and water recycling makes the process not only highly attractive technically and economically, but also sustainable, reducing both carbon and water footprints. Following proving trials carried out at three distilleries it is calculated that, by using AnMBR, a typical 8Mla distillery would benefit by approximately £800,000pa in energy and recycling water via reverse osmosis and the benefits in reduced discharge cost and mains water savings could easily add a further £100,000pa, as Figure 4 shows.

Figure 4

This type of project, converting by-products into valuable energy and recoverable clean water, can make a major contribution to the sustainability of distilleries and will set the new standard in the industry.

Hello!

I find this article very useful for my thesis.

I wanted to know if you could send it to me in the original version with the authors information and year of publication.

Thank you very much,

Regin

Hi Regin, this article was published in 2016. I’m afraid I do not have the author’s details but you can reference it as a New Food article. Good to hear it has been useful for your thesis.