Foreign material management and identification

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 12 November 2021 | Fabien Robert | No comments yet

Here, Fabien Robert highlights the importance of key foreign material management principles and introduces fast and effective tools to support root cause investigation.

While microbiological and chemical hazards are critical considerations, food manufacturers should not underestimate the importance of managing physical hazards, both in terms of potential food safety risks and consumer dissatisfaction.

Physical hazards may enter the food chain as contaminants, adulterants, or as foreign materials. It is thus of utmost importance to have a robust programme to fight against foreign material intrusion at different levels of the value chain. Once foreign materials are found, additional techniques are employed to enable their identification and can also be used to assist in determining their source. This proactive identification fosters a fast and effective investigation of the root cause and triggers a continuous improvement mindset.

A robust foreign material management approach

Foreign material represents about 10 percent of recalls; thus, is not the main reason for a recall issued by the US Food and Drug Administration (FDA). However, its absence in manufactured food products is one of the biggest drivers of consumer trust.

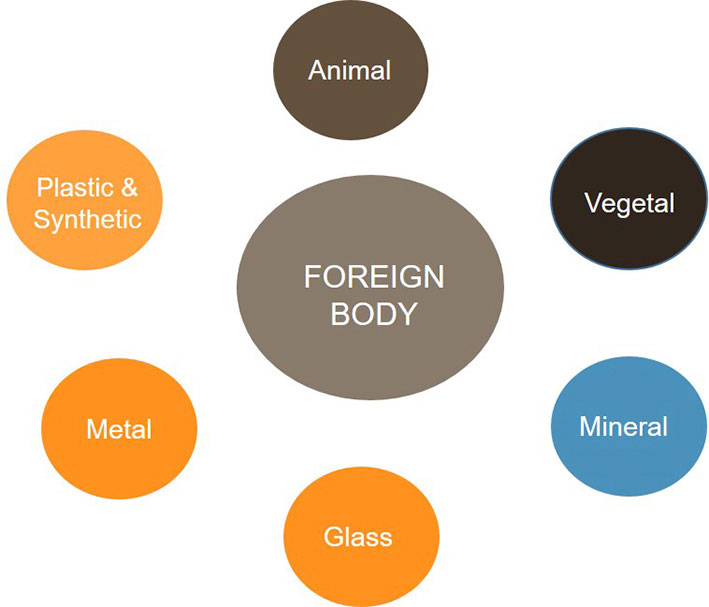

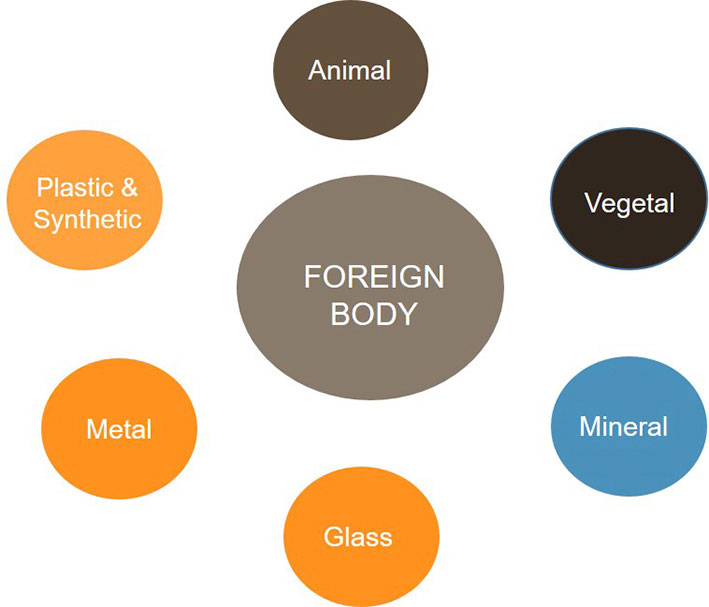

Indeed, foreign material is among the biggest causes of consumer complaints. ‘Foreign material’ is a technical term which refers to any extraneous matter – whether of a physical, chemical or biological nature – found in food. Usually, foreign materials render the food unfit for human consumption. Its origin and nature, as expressed in Figure 1, can be biological (animal, vegetal, insect, human), plastic (packaging, raw material, containers), mineral (stones, commodities, minerals), metal (processing, commodities) or glass (packaging, commodities).

Another way to define foreign material could be anything that the consumer does not expect to find in the purchased product. A foreign material management approach can be established based on the following three principles:

1. It is the responsibility of management at all levels of the company

2. It is defined by the customer and the consumer

3. Zero is the only acceptable target.

Figure 1: Illustration of various natures of foreign materials

This management includes, among other elements, understanding the risk factors by building awareness internally and externally, promoting best practices, and developing preventative action with vulnerability assessments, mitigation plans and continuous reviews. Management should be secured all along the value chain from the first tier of suppliers to the consumer, with an exhaustive audit and review plan with suppliers and raw material producers. Alongside this, within the factory there should be risk mapping, zoning, thorough maintenance planning and detection systems on the line – all are key elements of success.

Obviously, the final feature of an effective programme addresses the company’s culture around quality and food safety. Without the right mindset, a strong behaviour footprint, and the right practice and training in place, all other components of the programme will not be effective.

The food safety culture of the company establishes the base of the pyramid of your foreign material management programme and remains essential throughout. Adequate measures and performance framework around your programme will foster progress and improvement in your foreign material incidents challenge.

Reactive and proactive analytical method capability

One element of foreign material management that is often insufficiently considered is the use of analytical tools, both in a reactive and proactive mode. In a reactive mode, once a foreign material is found, investigation of the root cause is key to eradicate the issue and avoid repetition. Determination of the nature of the foreign material helps the investigation, especially if there is comparable reference material. It allows validation of consumer findings and enables one to identify the source of the foreign material.

Adopting a proactive stance, building a library of possible foreign materials enables faster problem solving. From an analytical viewpoint, various analytical techniques can be used; the most common ones are microscopy, fourier transform infra-red (FTIR) spectroscopy and X-Ray fluorescence (XRF) spectroscopy. Sometimes more specific techniques, such as Raman spectroscopy, electronic microscopy, elemental analysis, or other specialised methods are employed.

Microscopy combined with or without a filth test is frequently used for animal or human origin foreign material confirmation. Coupled with proper entomology skills and an adequate database, it is a simple and powerful approach – easily differentiating human from rodent hair or helping to identify an insect’s origin in case of global international trade.

FTIR is commonly used to detect organic material, such as plastics and any polymer‑based materials, is a non-destructive technique and can be a bench-top or portable device. The principle relies on the specific atom’s bond vibration (stretching, bending, twisting) allowing function identification on one part of the spectrum and fingerprinting on the other. A vast array of spectral libraries are available for searching unknowns and strengthens for the application of this technology.

XRF is generally a portable, non-destructive technique and the acquisition only takes a couple of minutes. The principle is based on a primary X-ray hitting an inner shell electron of the atom and ejecting the electron from the atom. The open position is filled by an electron from a further outer shell and fluorescence radiation is emitted. This radiation is specific to each metal and leads to the composition identification of the metallic piece.

XRF can be used on samples from a few millimetres to full-sized equipment. It is the best tool for any metallic foreign material, as it provides the elemental composition and allows for alloy identification and recognition of specific pieces of equipment on your production line. Having a robust database with a full library of your line equipment makes the tool more effective and stronger when used in investigation.

These analytical techniques are powerful tools in the identification of metals, plastics and insects, helping to strengthen the robustness of foreign material management, identification and elimination. This investigative approach is comparable with the use of whole genome sequencing techniques for pathogen identification when a fine root cause identification is needed. They will never replace the proper measures required to avoid the presence of foreign material in your finished products, but should be a complementary approach of continuous improvement in your overall foreign material management programme.

Beyond supporting the root cause analysis of the incident, it is also an important element to bring scientific evidence in case of dispute with a supplier, customer or consumer.

About the author

Fabien Robert has worked for Nestlé for over 20 years in R&D, quality and regulatory, and is currently Head of zone AMS for Nestlé Quality Assurance centres. Prior to this, he earned a PhD in organic chemistry.