How are on-pack cooking instructions validated?

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 4 August 2021 | Audrey L’Yvonnet | No comments yet

Audrey L’Yvonnet explains the validation process of on-pack cooking instructions and identifies why cold spots are so important for manufacturers.

How do manufacturers decide which cooking instructions to include on food packaging?

The validation of on-pack cooking instructions is the safety control step for raw products which do not have another earlier step to sufficiently control the microbial pathogen risk.

Cooking validations are carried out to provide consumers with the correct cooking instructions, information and re-heating guidelines to ensure ready meals and food products are safe to consume. The cooking instructions must be sufficient to achieve the pasteurisation process of 70°C for two minutes (or an equivalent combination) as recommended by the Food Standards Agency (FSA). Equivalent time-temperatures to the pasteurisation process of 70°C for 2 minutes are, for example:

- 60°C for 45 minutes

- 65°C for 10 minutes

- 75°C for 30 seconds

- 80°C for six seconds

The organoleptic quality of the cooked product must also be taken into consideration, for it is a key criterion for consumer satisfaction and re-purchase. Appropriate and documented validated cooking instructions are therefore paramount for food safety, organoleptic quality, and brand reputation.

Cooking validations can be performed either by time-temperature profiling during cooking or via challenge testing. Cooking validations via time-temperature profiling during cooking allow the identification of the minimum cooking time required to achieve a product that is safe to eat. Any additional cooking time is then aimed at achieving a product of acceptable organoleptic quality for the consumer.

Combining cooking validations data and sensory analysis therefore provide useful information when reducing a product cooking time is required to achieve a better organoleptic quality.

Cooking Validation – Testing

Cooking validations via time-temperature profiling involve the measurement of the product cold spot temperatures during cooking. The product cold spots are the areas in the product that take the longest to heat and are consequently critical from a food safety point of view. The location of the cold spots in each product will vary depending on the cooking method. Variation in the cold spot locations has also been observed in the same product cooked in different microwave makes and models.

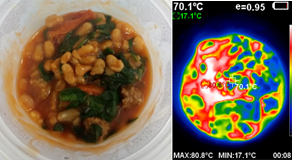

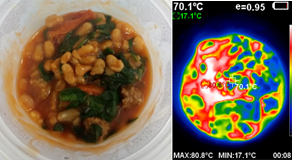

Cold spot identification is performed using thermal imagery, in triplicate, for each cooking device to test. For each replicate, comparison between thermal picture and real picture enables the cold spots to be identified.

The blue areas on the thermal image are the cold spots of the product

A new set of at least three samples is then used for the cooking validation trials. Temperature probes are inserted at the cold spots in the product, which is then cooked as per instructions.

Cold spot temperatures are recorded during the full duration of the cooking. The resulting data allows the identification of the minimum cooking time for the product to be safe to eat

Sensory analysis

Then comes sensory analysis: is the product cooked with the minimum cooking time more acceptable to the consumers? If not, how much additional cooking is required to reach the best organoleptic quality? Consumer testing will answer these questions.

Consumer tests – also called subjective tests – provide information on consumers’ acceptance of a product (degree of liking) or preference between two products. Such tests are run with a high number of consumers representative of the population. Typical questions asked are “how much do you like this product?” or “which product do you prefer?”.

Conclusions drawn from the consumer tests will allow the determination of the optimum cooking time from an organoleptic point of view. Optimised cooking instructions will then be determined by combining the data provided by cooking validations and consumer testing.

About the author

Audrey L’Yvonnet works as a Sensory Study Manager at ALS Laboratories UK Limited, supervising the sensory activities and cooking validation services within the Consultancy Team. He has worked for ALS for five years. He holds an engineering degree in Food Sciences and Human Nutrition, with specialisations in Sensory Science and Biotechnologies.