It’s time to turbocharge your cooking process

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 18 September 2018 | OAL | No comments yet

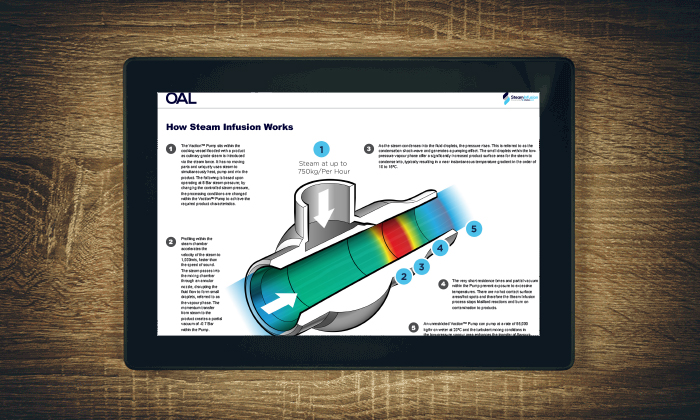

Manufacturers are under more pressure to produce food without increasing their factory footprint. Speeding up cooking processes using technology such as Steam Infusion can dramatically increase productivity without compromising the end product. See the graph below demonstrating how the speed of heating 1,000kg in a 2,500kg kettle changes depending on the cooking method…

The technology cooks from the centre of the vessel outwards and the low-pressure vapour phase coupled with the short residence times mean the ingredients do not see excess temperatures whilst processing. For food manufacturers, this increases yields as the lack of burn on reduces the amount of product wasted and improves product consistency as the risk of subsequent batches being contaminated is significantly reduced.

What is Steam Infusion Best For?

The matrix below scientifically ranks food products on Steam Infusion’s ability to create a differentiated product (flavour, nutritional, colour etc.) against the ability to improve the operational efficiency of production (production time, cleaning, energy etc.). The findings are from a £978,246 Innovate UK* funded “Nutrition for Life” project with the University of Lincoln that scientifically explored the operating envelope of the Steam Infusion Vaction™ Pump.

The rest of this content is restricted - login or subscribe free to access

Why subscribe? Join our growing community of thousands of industry professionals and gain access to:

- bi-monthly issues in print and/or digital format

- case studies, whitepapers, webinars and industry-leading content

- breaking news and features

- our extensive online archive of thousands of articles and years of past issues

- ...And it's all free!

Click here to Subscribe today Login here