Is this food safe and does it pose a risk to public health? Going beyond ISO

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 6 September 2019 | Dr Trevor Lorman | No comments yet

Dr Trevor Lorman, Senior Director of Quality Assurance at Mérieux NutriSciences, explains the best way to build a global laboratory quality management programme.

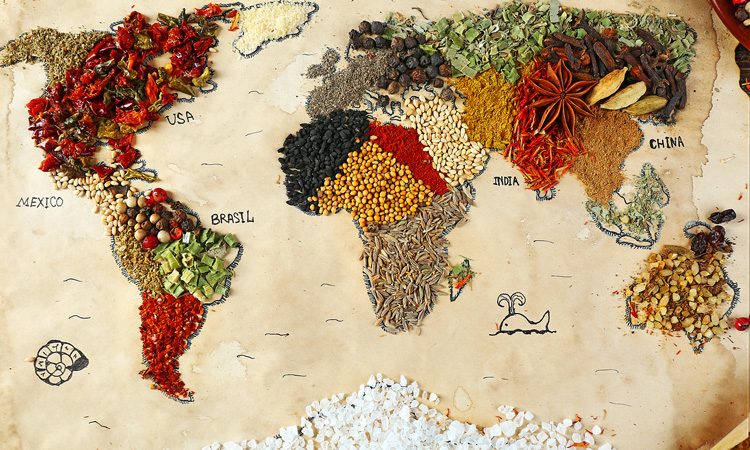

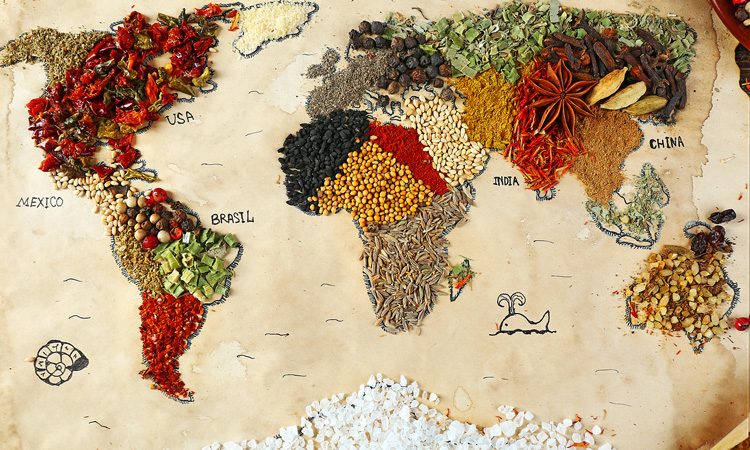

In an age of globalisation and increased exports to Europe, North America and other parts of the world from countries including India and China, one of the greatest questions faced by importers or exporters is: ‘Is this food safe and does it pose a risk to public health?’

Exporters and importers often have limited internal testing facilities. Another factor these companies are faced with is regulatory bodies requiring independent test data rather than data from an internal laboratory. Hence, exporters and importers are relying more on independent third-party testing laboratories to provide reliable, accurate data.

With the challenge of ensuring accurate data across different countries and regions, food producers are turning to laboratories with a global presence and a standardised global quality system, staffed by experts in food testing that have not just knowledge of local mandates, but global expertise too.

For food testing laboratories, the first step in achieving the target of a global quality system is accreditation to ISO 17025 by the local accreditation body. It is important to remember that ISO 17025 is the minimum standard laboratories must reach in terms of a quality system. The challenges facing a truly global network of laboratories is ensuring the same quality across all laboratories through different countries. This can be achieved by setting a standard higher than ISO 17025 as well as implementing global methods and a global quality manual.

The next stepping-stone to developing a truly global quality system is a fully integrated system of procedures including technical and quality requirements. A global network of laboratories must also have technical standards that apply to all facilities. With the goal of achieving reliable, accurate data as well as maintaining the quality standard across the network, a centralised (or corporate) quality team is required, which not only sets and defines the quality and technical standard but holds the laboratories accountable to these standards.

This corporate team monitors the performance of the laboratories throughout the entire network with no exception; this team must be independent of the actual laboratory. The tools the corporate quality team employs in this oversight role includes setting Key Quality Indicators, performing corporate quality system audits and technical method audits. Then, using fully transparent and open tools – usually website-based – the corporate team monitors the performance of the laboratories against the defined standard.

Some of the major elements of a global quality system are global standard operating procedures (SOPs) that are applicable to every laboratory in the network. This includes design and layout, equipment validation and verification, method verification and introduction, plus control charts and handling of non-conformances and customer complaints.

Our global network of laboratories employs many approaches to go beyond the ISO standard and ensure a consistent quality system. A few notable practices include:

1. Evaluation of the suitability of particular microbiology methods for specific product matrices to ensure meaningful results

The Food Safety Modernisation Act (FSMA) has increased the focus on demonstrating that the methods work for the matrix. Additional validation or verification work may be necessary to address this increased scrutiny for proof of method suitability. The validation for rapid methods covers broad food categories, but food products and formulations within a category are often very diverse. The Food and Drug Administration (FDA) requires matrices not included in the validation to be evaluated via a matrix extension (verification study), with the establishment (food manufacturer) being ultimately responsible for ensuring that the sampling and testing method meet.

Standard reference methods or commercial methods with validation recognised by regulatory bodies are also used. Validation data supports the method is fit-for-purpose. However, the number of matrices and the analytical sample size included in a validation is often limited. A review of the specific matrices and analytical sample is needed to determine if the test matrix is included in the validation or if additional studies are required. In the case where the test matrix or desired analytical weight is not included in the validation study, matrix extension (verification) or validation is required to show the method is appropriate for the sample type and/or analytical weight.

This data will support that the method enrichment protocol is appropriate for recovery of the target organism from the matrix, giving confidence that a negative result is a truly meaningful result.

2. Use of control samples and fast detection of cross-contamination

A technical requirement for a truly global quality system include global control samples tested in every laboratory and a proficiency testing programme from an accredited provider, applicable to every laboratory.

As we are committed to going beyond the standard, our laboratories dedicate roughly 20 percent of chemistry testing and 10 percent of microbiology testing to our quality assurance programme.

Additionally, our microbiology laboratories use a proprietary genetically marked positive control. This allows us to – within hours – identify if there has been any occurrence of cross-contamination between the positive control and customer samples; thereby resolving any doubt of false positives caused by control samples faster than alternative approaches,

3. Visualisation of the laboratory environmental monitoring programme with automated scheduling and corrective actions using the EnviroMap platform

Manufacturers are continuously evaluating and monitoring their facility’s environment for bacteria and indicators as a proactive measure to ensure no cross-contamination occurs from the environment to their product; this should be no different for laboratories. Understanding the eco-system and environment is an important part of any laboratory quality programme.

Our laboratories use EnviroMap, a secure, cloud-based system that allows automation of environmental monitoring programmes. With a clear visual of the laboratory floor plan and map, it helps to identify cross-contamination and prevent reoccurrences. The software automates scheduling, provides interactive dashboards, maps results, sends instant notifications, and supports corrective actions and traceability.

One of the few examples of a truly global integrated quality system is the one that is followed by all 100+ laboratories located in 24 countries of the Mérieux NutriSciences network – with local staff expert in the testing and regulatory requirements for that region. Plus, oversight is provided by the corporate team with its expertise in global testing and regulatory requirements.

About the Author

Dr Trevor Lorman is an experienced analytical chemist with 25 years of experience in food testing and a PhD in analytical chemistry. He joined Silliker-later Mérieux NutriSciences in 1998 as a Senior Consultant Chemist. In May 2009 he moved to Shanghai PRC joining the Silliker China team as Asia Director of Chemistry & Quality. In addition to this role, he has taken over as Operations Manager for the Silliker China laboratories covering chemistry and microbiology testing.