The present and future of ultra-high pressure homogenisation

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 20 August 2020 | Eduardo Puértolas, Elena Santacruz, Saioa Alvarez-Sabatel, Sonia Garcia | 1 comment

AZTI researchers tell New Food about the opportunities of an emerging technology and the work in progress to develop it for commercial use.

Ultra-high pressure homogenisation (UHPH) is an emerging technology with potential application as an alternative to conventional thermal pasteurisation and/or sterilisation in pumpable foods, eg, milks, juices, sauces, etc. Beyond its application to improve the safety of these goods, the high magnitude of the applied forces can lead to other useful applications such as enzyme inactivation, physical stabilisation, texturisation, functionalisation of some ingredients, or the preservation and extraction of compounds of interest. The combination of all these applications, together with the advances on the scaling-up of this technology for industrial necessities, puts this tech in a promising competitive position.

UHPH, an overview of the technology

UHPH is an emerging technology for the treatment of fluid food products. Although its operation is based on the same principles as conventional homogenisation (working pressures of up to 50 MPa), the development of new designs and more resistant materials has led to the creation of equipment that can reach even higher pressures (up to 400 MPa1).

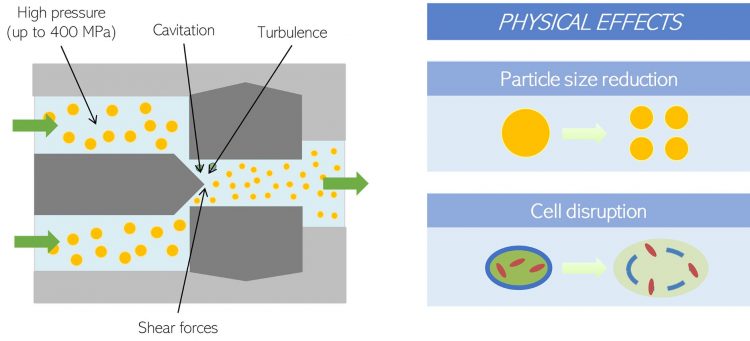

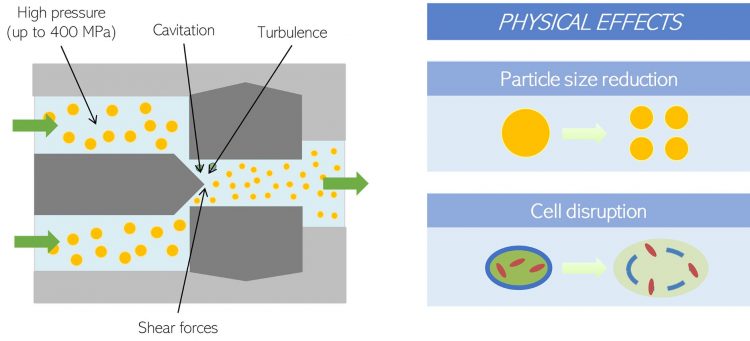

The UHPH process is mostly used in the positive displacement of a fluid at high pressure through valves or nozzles of small diameters (Figure 1). As a consequence of the after-valve depressurisation, different homogenising forces of great magnitude appear: shear, impact, cavitation, turbulence, etc. These forces, whose magnitude and effect will depend on the characteristics of the fluid (eg, viscosity), processing parameters (eg, pressure, inlet temperature) or equipment (eg, valve design) are responsible for particle size reduction and microbial inactivation, among other effects. It should be noted that although the occurrence of these forces results in the dissipation of energy in the form of thermal energy, due to the low retention times (<0.1 s), it is considered a non-thermal technology.2

An alternative for conventional pasteurisation and sterilisation

Foods are typically thermally processed in order to reach the microbial reduction needed for assuring appropriate safety and shelf life levels. However, it is well-known that thermal processing negatively affects the food quality and freshness, since some relevant health and sensory related compounds are thermolabile. Based on its effects on microorganisms, UHPH technology has been proposed as a non-thermal alternative for preserving and homogenising pumpable foods, such as vegetable juices, smoothies, egg-based products, broths, sauces and dairy products.2,3 The applied pressure and the inlet temperature, which both determine the temperature reached in the UHPH valve/nozzle, have been considered the main factors affecting the microbial inactivation.2 However, the composition and characteristics of food, for example pH, NaCl concentration, viscosity, influence the obtained microbial reductions.3

The UHPH process is mostly used in the positive displacement of a fluid at high pressure through valves or nozzles of small diameters

From a general point of view, pressures above 200 MPa allow the inactivation of vegetative microbial cells.2,3 Applying inlet temperatures below 25°C and pressures around 300 MPa, five log reductions are typically reached for the most relevant pathogenic and spoilage bacteria.3 These pressure-inlet temperature combinations did not result in the appearance of heat indicators in foods like milk, so it could be a good alternative to thermal pasteurisation.3

UHPH is also a promising technology for sterilising pumpable.3,4 Due to the homogenising forces, the food temperature approximately increases between 15 and 25°C per 100 MPa at the outlet of the homogenisation valve/nozzle. This increase varies in function of the valve/nozzle set-up and the food characteristics. At inlet temperatures between 60 and 85°C, pressures of 300 MPa allows temperatures to reach at least 120°C in less than 0.1s. This pressure-temperature combination can reduce the bacterial spores load present in the product, based on both the thermal effect and the homogenisation forces. As UHPH‑mediated heating is extremely fast, the product suffers less heat damage than in conventional thermal sterilisation, improving the nutritional and sensory characteristics with respect to thermal treatments.

Beyond food safety, other applications

Beyond its function to preserve food from a microbiological perspective, UHPH technology has proven to have many more functions of interest to the food industry. Among others, the application of UHPH forces can be used for the following purposes:

Enzyme inactivation

Several studies have shown UHPH decreases the activity of some enzymes, helping to improve the product shelf life. For example, in cow’s milk a complete inactivation of the lactoperoxidase has been described at 300 MPa.5 Moreover, at this pressure, an inactivation of polyphenoloxidase, responsible for the deterioration of colour, flavours, etc., in apple juice has been detected.6

Physical stabilisation and texturisation

One of the main effects of the UHPH forces is the significant reduction in fluid particle size. In emulsions, these particles are mainly fat droplets, while in other products more solid‑like particles are found (eg, fibres and cocoa particles). A reduction in their size leads to an improvement in the physical stabilisation of the products, delaying or avoiding separation phenomena (eg, cremation, sedimentation). Particularly in emulsions, this provokes an increase of the overall viscosity, allowing to decrease the final fat content while maintaining the sensory properties of the full-fat counterparts.1 For a single formulation, different textures can be achieved with the application of different pressures.

Figure 1: Schematic representation of a common UHPH device (piston-gap) and the main effects of this technology on fluids.

Functionalisation of ingredients

The improved technological functionality of some ingredients after UHPH has also been described. In whey proteins, structural changes can unmask buried hydrophobic groups improving their foaming capacity.7 Inulin also significantly improves its gelling behaviour due to an improved crystallisation.8 However, UHPH can negatively affect other thickeners, including some starches, xanthan gum, etc., decreasing their thickening properties. Therefore, specific formulations are required for UHPH-processed products.

Preservation and/or extraction of compounds of interest

In contrast with thermal treatments, due to the lower impact of temperature, some thermolabile compounds can be effectively preserved with UHPH. For example, in UHPH‑processed apple juice, vitamin C content is similar to the raw samples.4 Regarding the extraction of molecules, especially in vegetal matrices, UHPH forces can provoke cell disruption, facilitating the release of some compounds of interest. In some algae, the disruption of algal cell walls improves the oil extraction.9 Furthermore, in some cases an increased in vitro bioaccesibility of bioactive compounds can be achieved, as demonstrated with α- and β-Carotene in carrot emulsions.10

Recent advances in the technology and industrial accessibility

Despite the good results obtained on a laboratory scale during the past century and the range of possible applications, the industrial development of the technology was limited for many years due to the lack of sufficiently resistant and scalable materials and components. During the last decade, the first pilot units (up to 300 L/h) capable of reaching pressures up to 350 MPa arrived on the market. Currently, several units are installed worldwide for food research and development (R&D) and demonstration purposes (Figure 2). Based on these pilot developments, most scalability problems have been solved, and several companies, such as BEE international (USA) and Ypsicon (Spain), have started to design the first industrial systems. However, to the best of our knowledge, no manufacturer has yet built industrial units for producing foods for the market.

Figure 2: Example of a UHPH pilot unit (130 L/h) constructed by Ypsicon (Spain).

The most relevant remaining challenge of UHPH scaling-up is to adapt the technology components to high viscosity products, like sauces, creams or some dairy products, reaching the flow necessities of the industry (up to 10,000 L/h), without sacrificing performance. At this point, it is necessary to remark the work being conducted in the underPRESSURE project, funded by EIT Food (European Institute of Innovation and Technology, European Union). In this project, a consortium of European companies (AZTI, Puratos, Acesur, Fraunhofer and Ypsicon) are working to adapt UHPH technology to the requirements of the viscous foods and to validate it in a close-to real operational environment. This new generation of UHPH technology is expected to be available by 2021, opening new industrial possibilities.

Conclusions

UHPH has solid potential for the food industry, not only for preserving pumpable foods, but also for developing new food products and applications. The reduction of the heat damage respect to conventional thermal processes represents a clear advantage for the food industry. The initial industrialisation steps have been taken and the first UHPH products are expected to be on the market in the next few years. In any case, due to the great influence of the food components and its intrinsic characteristics in the process efficiency, the industrial use of UHPH requires the optimisation of the full process for each specific product and application.

References

1. Alvarez-Sabatel S. High pressure homogenisation for emulsion fat reduction [Thesis dissertation]. Spain: University of the Basque Country; 2016.

2. Zamora A, Guamis B. Opportunities for ultra-high-pressure homogenisation (UHPH) for the food industry. Food Eng Rev. 2015;7(2):130-142. doi:10.1007/s12393-014-9097-4

3. Patrignani F, Lanciotti R. Applications of high and ultra high pressure homogenization for food safety. Front Microbiol. 2016;7(August):1-13. doi:10.3389/fmicb.2016.01132

4. Suárez-Jacobo Á, Rüfer CE, Gervilla R, Guamis B, Roig-Sagués AX, Saldo J. Influence of ultra-high pressure homogenisation on antioxidant capacity, polyphenol and vitamin content of clear apple juice. Food Chem. 2011;127(2):447-454. doi:10.1016/j.foodchem.2010.12.152

5. Pereda J, Ferragut V, Quevedo JM, Guamis B, Trujillo AJ. Effects of Ultra-High Pressure Homogenization on Microbial and Physicochemical Shelf Life of Milk. J Dairy Sci. 2007;90(3):1081-1093. doi:10.3168/jds.S0022-0302(07)71595-3

6. Suárez-Jacobo Á, Saldo J, Rüfer CE, Guamis B, Roig-sagués AX, Gervilla R. Aseptically packaged UHPH-treated apple juice: Safety and quality parameters during storage. J Food Eng. September 2011. doi:10.1016/j.jfoodeng.2011.09.007

7. Bouaouina H, Desrumaux A, Loisel C, Legrand J. Functional properties of whey proteins as affected by dynamic high-pressure treatment. Int Dairy J. 2006;16(4):275-284. doi:10.1016/j.idairyj.2005.05.004

8. Alvarez-Sabatel S, Marañón IM De, Arboleya JC. Impact of high pressure homogenisation (HPH) on inulin gelling properties, stability and development during storage. Food Hydrocoll. 2015;44:333-344. doi:10.1016/j.foodhyd.2014.09.033

9. Samarasinghe N, Fernando S, Lacey R, Faulkner WB. Algal cell rupture using high pressure homogenization as a prelude to oil extraction. Renew Energy. 2012;48:300-308. doi:10.1016/j.renene.2012.04.039

10. Svelander CA, Lopez-Sanchez P, Pudney PDA, Schumm S, Alminger MAG. High Pressure Homogenization increases the in vitro bioaccessibility of α- and β-Carotene in carrot emulsions but not of lycopene in tomato emulsions. J Food Sci. 2011;76(9):H215-H225. doi:10.1111/j.1750-3841.2011.02418.x

About the authors

Im very interested in the application of this technology in the meat industry. Ive worked with similar systems for some time now and would love to contact a manufacturer of this equipment. My mail adres is ebenvt at (@) gmail.com