If you can’t kill them, control them

Posted: 9 March 2006 | Peter de Jong and Meike te Giffel, NIZO food research, The Netherlands | No comments yet

In the food industry the operation costs are governed by fouling. Typically, processes applied in the dairy industry that operate below 80°C are limited by adherence and growth of micro-organisms in the equipment. Above 80°C the run time is limited by deposition of proteins and minerals. Besides the limited run time, bio-fouling may have implications for product spoilage.

Adhered spoilage organisms may be released to the product during processing. For example, the adherence and release of bacteria and bacterial spores in a milk pasteuriser may lead to defects such as excessive openness or late-blowing in cheese or taste deviations.

In the food industry the operation costs are governed by fouling. Typically, processes applied in the dairy industry that operate below 80°C are limited by adherence and growth of micro-organisms in the equipment. Above 80°C the run time is limited by deposition of proteins and minerals. Besides the limited run time, bio-fouling may have implications for product spoilage. Adhered spoilage organisms may be released to the product during processing. For example, the adherence and release of bacteria and bacterial spores in a milk pasteuriser may lead to defects such as excessive openness or late-blowing in cheese or taste deviations.

In the food industry the operation costs are governed by fouling. Typically, processes applied in the dairy industry that operate below 80°C are limited by adherence and growth of micro-organisms in the equipment. Above 80°C the run time is limited by deposition of proteins and minerals. Besides the limited run time, bio-fouling may have implications for product spoilage.

Adhered spoilage organisms may be released to the product during processing. For example, the adherence and release of bacteria and bacterial spores in a milk pasteuriser may lead to defects such as excessive openness or late-blowing in cheese or taste deviations.

Despite all the efforts of applying hygienic design and using new technologies such as surface coating or electrolytic polishing, both types of fouling still occur in all food production processes. If fouling cannot be avoided the next best solution is to control and minimise the amount of fouling. Therefore, it is necessary to know the effect of food composition and production conditions on the type and amount of fouling; preferably in a quantitative form. Predictive computer models turn out to be an excellent tool to realise this and to control bacterial growth in such a way that operating costs are decreased.

Fouling mechanism

In the 1980s the first attempts to describe the fouling mechanism in a more qualitative way were reported. It was determined that β-lactoglobulin is the key component in milk responsible for the deposition of proteins and minerals. In the 1990s more quantitative fouling models were developed, enabling the prediction of the location and amount of deposition as a function of product composition and process conditions. Nowadays, these models are applied in process design and even in process control (Smit et al., 2004).

With some delay, a similar path was followed in the control of bio-fouling. Although it was assumed for a long time that, for example, in pasteurisation processes adherence of thermophilic bacteria causes the contamination of the pasteurised product during processing, this was first proven in the early 1980s (Bouman et al., 1982). In the late 1990s the first attempts were made to develop a quantitative model that predicts the bacterial counts in heated milk as a function of raw milk quality, equipment design and operating conditions (De Jong et al., 2002).

Predictive model

In an extensive study by NIZO food research a mathematical model has been developed which describes the contamination of food as a result of adherence, growth and release of bacteria in processing equipment (De Jong et al., 2002). The model was developed in three stages. First, the effect of flow characteristics on the adherence of Streptococcus thermophilus strain B123 was studied by rotating disk experiments. Next, the model parameters were estimated using experiments with a plate heat exchanger. Finally, the model was validated in a complex industrial environment by predicting the concentration of S. thermophilus during the processing of whey.

It was found that the contamination of bacteria is governed by the following mechanisms:

- Adherence of a bacteria from the product to the surface

- Growth of the bacteria at the surface

- Release of the bacteria to the passing product

- Inactivation of a part of the bacteria in the higher temperature regions

The predictive model developed incorporates all these mechanisms in three basic equations defining the bacteria concentration as a function of production time and position in the process:

- Change in wall coverage with time = Grown at the surface – Released + Adhered

- Change in bulk concentration with position = Released – Adhered + Grown in the bulk – Inactivated

- Change in bulk concentration with time = – Dilution by entering liquid + Released – Adhered + Grown in bulk – Inactivated

More details and mathematical equations are given in the literature (De Jong et al., 2002).

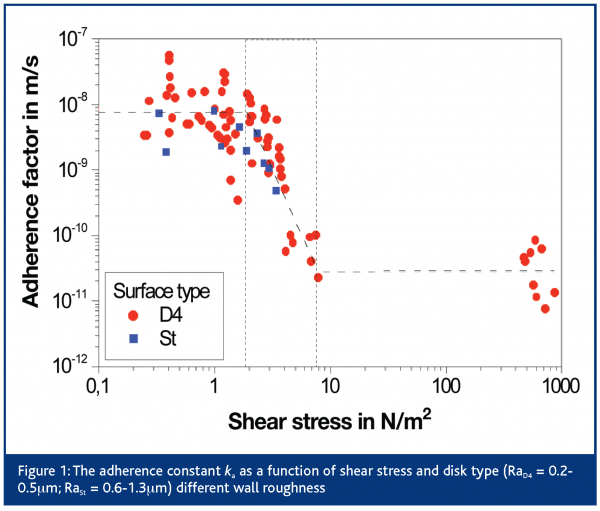

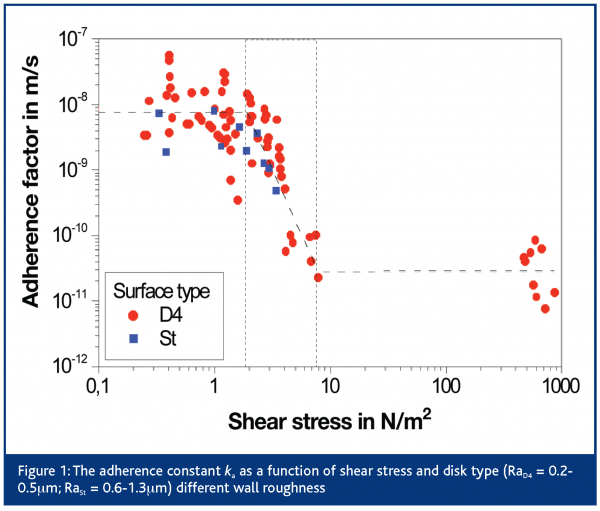

Effect of shear stress

It is generally assumed that increasing the flow rate or shear stress of the product along a surface will decrease the amount of adhered bacteria in equipment. As shown in Figure 1 this is more or less a valid assumption. The measured adherence constants are shown as a function of the shear stress. Although the data points are scattered, three regions can be distinguished. At a shear stress lower than 1 N m-2 and higher than 10 N m-2 the adherence is not influenced by shear stress. The intermediate region shows a decline of the adherence constant as a function of shear stress. It seems also that the roughness of the stainless steel surface has no significant effect on the adherence constant. Since in most practical situations the shear stress in flowing systems is approximately 1 N m-2 it makes sense to increase the shear stress in processing equipment.

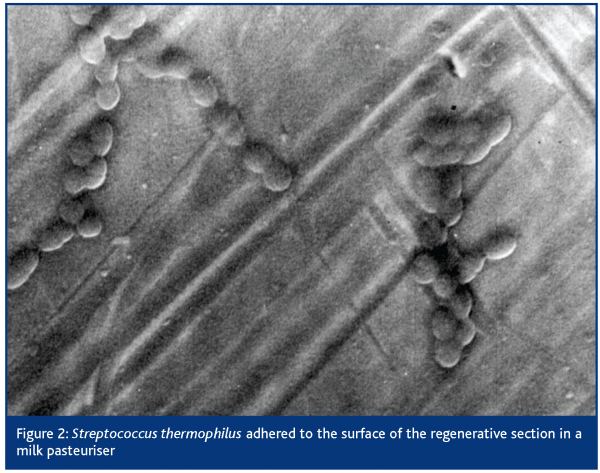

Effect of deposition

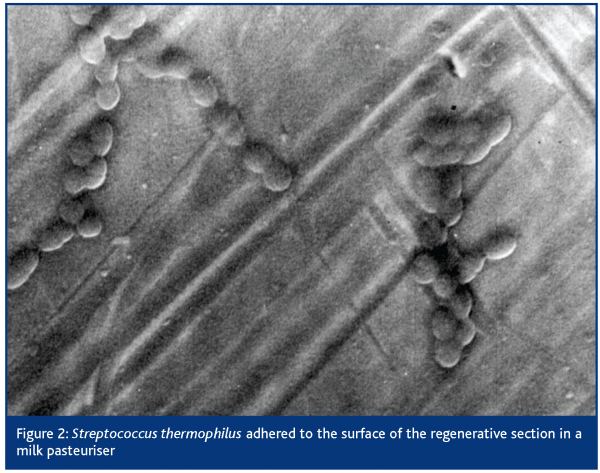

Sometimes it is stated that the deposition of proteins, minerals and fats at equipment surfaces is a prerequisite for bacterial contamination. As shown in Figure 2, bacteria can easily survive and grow on clean surfaces. Since bacteria from raw milk adhere and grow at temperatures below 80°C, the contamination originates from apparently clean equipment surfaces. This implies that, for example, in pasteurisers there will always be some contamination regardless of the cleaning procedure.

Effect of process configuration

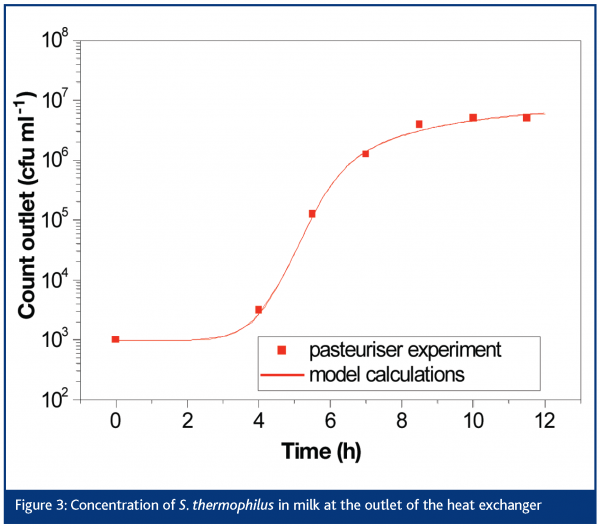

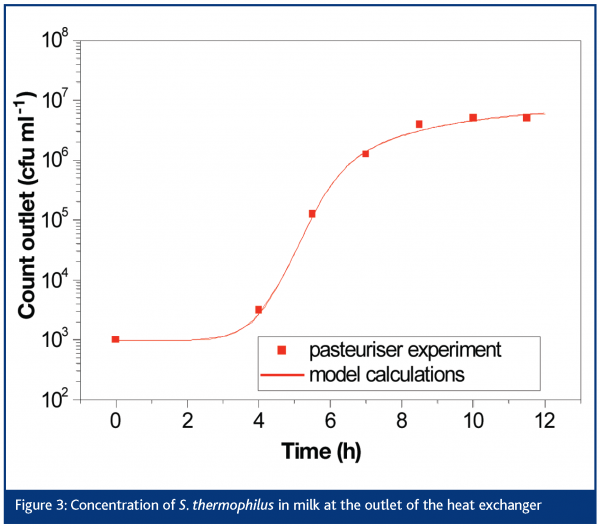

In order to test the model some validation studies with different process configurations were performed. In one case the outlet of a milk pasteuriser was sampled. Based on the bacterial counts in these samples the adherence factor was fitted. Figure 3 demonstrates that the model describes the course of the concentration in the bulk very well.

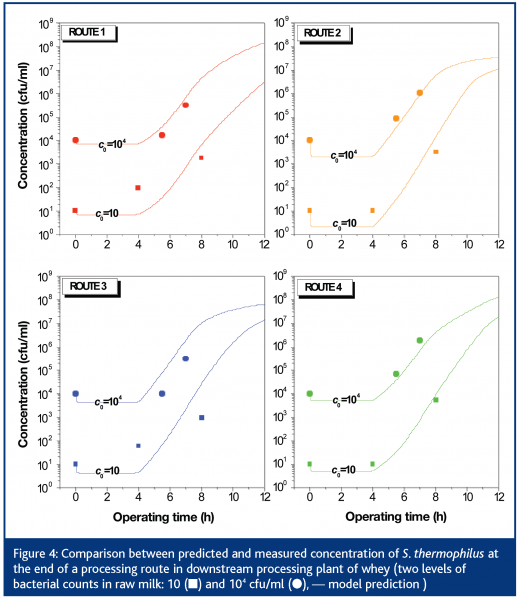

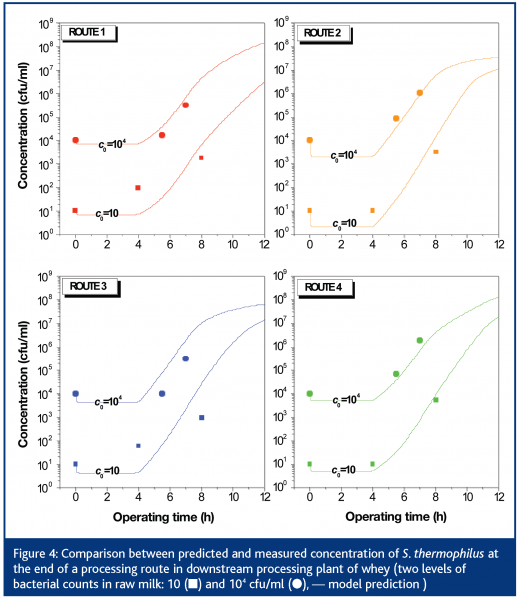

To validate the model in a practical situation, two production cycles were evaluated: one with a low initial bacterial contamination of the whey (10 cfu ml-1) and one with a high initial contamination (104 cfu ml-1). In Figure 4 the results of the measured contamination at the end of each route are compared with the predicted (not fitted) values by the model. During the initial 4 hours of operation the outlet concentration was lower than the inlet concentration, due to the pasteurisation that results in inactivation of bacteria. After 4 hours the growth of bacteria overrides this inactivation and the outlet concentration increases with time. After 8 to 10 hours the curves level off because the steady state situation becomes closer. In conclusion, the model appears to predict the state of contamination in industrial production lines quite well. This opens opportunities for improvements in process configuration and operating conditions.

Controlling bio-fouling in dairy production

With the validated model available it is possible to design and operate processing equipment in such a way that the bacterial contamination is minimised. For example, when considering a milk pasteuriser the following control factors can be recognised:

- Heating temperature – A higher heating temperature will obviously increase the heat inactivation of the bacteria and result in less contamination. However, increasing the temperature will also increase product degradation

- Surface area of the heat regeneration section – In the case that the heat regeneration section of a pasteuriser is increased, a larger part of the heating is taken over by the regeneration. For example, a regeneration of 80% means that 80% of the heating from 5°C to 75°C takes place in the regeneration section (5 – 61°C) and 20% in the heating section (61 – 75°C). More surface area will provide bacteria with greater possibilities for adherence and growth. On the other hand, by increasing the surface area of the heat regeneration section the volume, the residence time and the outlet temperature of this section is also increased. This also increases the heat load and, as a consequence, the heat inactivation of bacteria

- Flow rate or shear stress – Higher flow rates in the pasteuriser will decrease the rate of adherence of bacteria. However, higher velocities increase the pressure drop of the system, resulting in higher investments for pumps and other processing appendages. On the other hand, it may be a solution to increase the velocity only in those equipment regions where adherence of bacteria is most critical

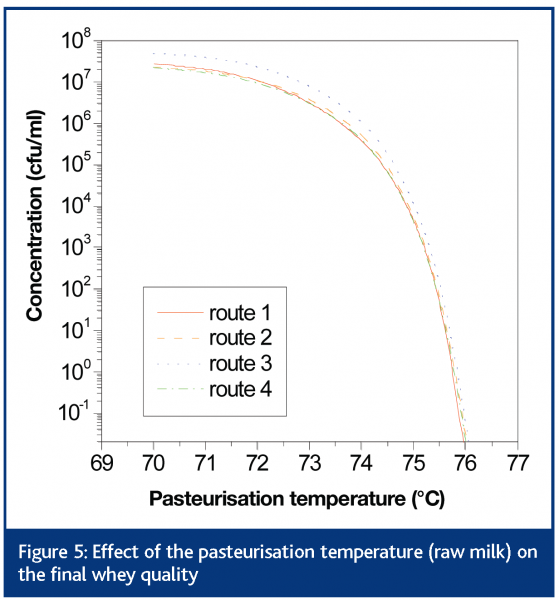

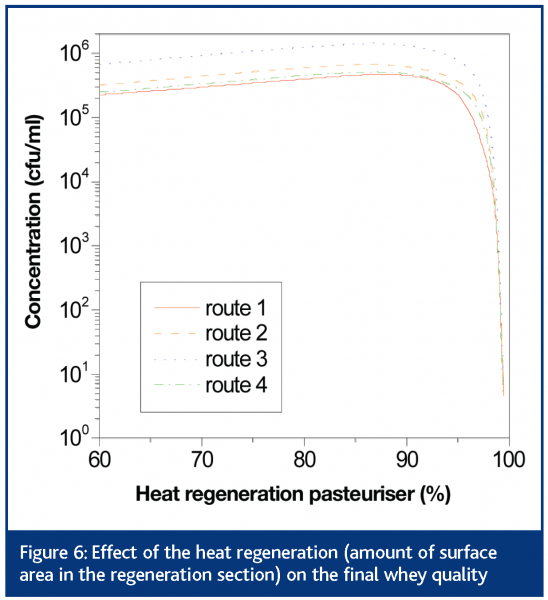

In Figure 5 and Figure 6 the effect of heating temperature and surface area of the regenerative section on the bacterial contamination in a pasteuriser is demonstrated. From Figure 5 it becomes clear that the pasteurisation temperature is an important factor in controlling the contamination level. For all processing routes the temperature should be set at 75-76°C. In the case that the actual pasteurisation temperature is 72°C the contamination is decreased by seven log cycles.

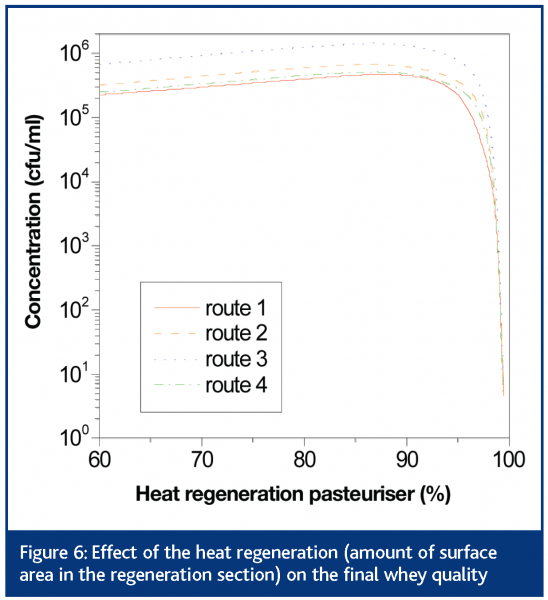

Figure 6 clearly shows the two effects of the amount of heat transfer area in the heat regeneration section of the pasteuriser. If less than 80 per cent of the heating takes place in the regeneration section, contamination increases with the amount of heat transfer area at which bacteria can adhere and grow. At higher regeneration percentages the contamination decreases drastically. This is caused by the higher heat load to the milk.

It is obvious that for optimal design and operation of the processing equipment other heat-induced product transformations should also be taken into account. For example, the tolerated level of protein denaturation for whey products is limited. With the predictive model for contamination and other product models available this can be easily achieved. Hence, it appears that this approach with the validated model enables better control of contamination.

Industrial benefits

The predictive model developed is the first quantitative model that takes account of both growth and adherence of micro-organisms in food production chains. From experiments on both pilot and industrial scale it is shown that the adherence of micro-organisms is a key phenomenon in bacterial contamination of food based on processing of liquid raw materials.

Overall, it can be concluded that for model evaluation on industrial scale the agreement between predicted contamination and measured contamination is very good. This implies that the model is of highly practical use in minimising the product contamination, extending run times of production chains or determining the critical points with respect to hygiene. For example, some years ago NIZO food research used the predictive model to design a new falling film evaporator plant for whey processing in the Netherlands. Validation measurements showed that this evaporator has the lowest operating costs ever determined (Vissers et al., 2002).

Since the model relates the quality of raw materials, the processing and the product quality, it may also be used for on-line and in-line process control. In this case the set-points of the production line are continuously optimised with respect to contamination. This method of controlling microbial contamination is expected to greatly benefit the food industry in the coming years.

References

Bouman, S., Lund, D.B., Driessen, F.M. and Smidt, D.G. (1982) Growth of thermoresistant streptococci and deposition of milk constituents on plates of heat exchangers during long operating times. Journal of Food Protection 45, 806-812

De Jong P., Te Giffel M.C. and Kiezebrink E.A. (2002) Prediction of the adherence, growth and release of microorganisms in production chains. International Journal of Food Micro¬biology 74, 13-25

Smit, F., Straatsma, J., Verschueren, M. and Jong, P. de (2004) NIZO Premia and Premic: Off-line and in-line product and process control tools for the food industry. In: Proceedings FOODSIM 2004 (Eds. Jong, P. de, Verschueren, M.) p100-102

Vissers, M.M.M., Jong, P. de, Wolff, J.J. de (2002), Nieuwe indampertechniek resulteert in zeventig procent energiebesparing [New evaporation technology results in 70% less energy consumption]. Voedingsmiddelentechnologie 35 (6) 20-22