Cross out contamination

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 24 June 2016 | Bjorn Thumas, Director of Business Development at TOMRA Sorting Food | No comments yet

According to the World Health Organization (WHO), an estimated 600 million people – almost 10 per cent of the global population – fall ill after eating contaminated food…

According to the World Health Organization (WHO), an estimated 600 million people – almost 10 per cent of the global population – fall ill after eating contaminated food.

Bjorn Thumas, director of business development at TOMRA Sorting Food

With safety regulations and global demand for food on the rise, optical and sensor-based sorting has become a necessity rather than a luxury for many producers who have previously relied upon manual sorting and inspection.

As a leading sorting systems manufacturer we see cross-contamination as an increasingly vital aspect of food safety. The reputational and financial impact of a product recall can be devastating for a company but sorting technology can be used to effectively manage cross-contamination issues.

Cross-contamination, or the presence of unexpected food matter in a supposedly homogenous food type, is a serious issue that can have significant implications for the global food industry. Headlines in 2013 reported the scale of the cross-contamination of meat products in the European horsemeat scandal, which wiped hundreds of millions of euros off the market value of well-established global supermarket brands. The impact of such errors can affect a wide range of foodstuffs meaning now, more than ever, the industry must ensure contaminants are identified and expelled from their products as early in the process as possible.

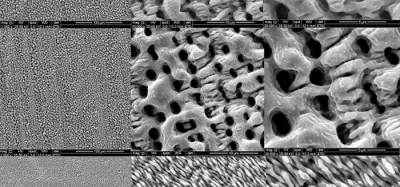

To combat the issues of contamination, many food manufacturers, processors and retailers are embracing the ever-changing technologies and systems available to them. TOMRA Sorting Food’s machines use a variety of sensors which go far beyond the common use of color cameras. Near Infra-Red (NIR) spectroscopy enables an analysis of the molecular structure of a product whilst x-rays, fluorescent lighting and lasers measure the elemental composition of objects. As well as its color and shape, an object’s surface structure and biological fingerprint can be effectively analyzed.

An important reason for the identification and removal of contaminants is to reduce the accidental spread of allergens. This is particularly important since the societal impact of causing an allergic reaction in an unsuspecting member of the public can have substantial repercussions, not only financially and legally, but also in terms of brand reputation.

Given the fact that 15 million Americans and 17 million Europeans have food allergies, the potential for significant problems soon becomes clear.

It may initially seem as though greater attention to the process food undertakes is all that’s needed to eliminate the potential for the spreading of contaminants but this is not the case. Contamination can not only be a result of unforeseen circumstances. In many instances, due to the locations used to grow certain products, items can easily end up mixed amongst other items, or through processes further down the line.

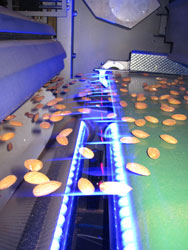

Peanuts, for example, by virtue of being a ground nut, can easily become contaminated with corn or soy. The size and color of both are not too dissimilar, making corn and soy hard to detect visually, but create the potential to cause serious problems should it not be ejected. Similarly acorns and peach pits can be found with almonds, causing potentially serious problems for manufacturers, processors, retailers and consumers alike.

The main issue is the way contaminants can be indistinguishable from the intended food type. The limitations of the human eye have forced a move towards sophisticated technology which can efficiently sort food, and these technologies are constantly being developed, enhanced and upgraded. As a provider of sorting solutions, TOMRA has been at the forefront of food safety and continues to develop advanced systems and technologies to remove contaminants of all types, including allergens.

Although relatively well-known, cross-contamination does not end with allergens. Due to variations in national food standards, the issues caused by cross-contamination can have a negative impact upon the global movement of food. For example corn, a commodity the US grows more of than any other country, can be grown naturally or genetically modified (GM). This difference is suitable for domestic markets but can cause issues internationally.

It is estimated that the United States exports between 10 and 20 per cent of its corn yield to global markets, the sales of which had a reported value of $7.6 billion in fiscal year 2014. When this is married with the fact that half the home nations within the European Union forbid the growing and importing of GM corn, organic corn from the US that has been cross-contaminated with its modified counterpart cannot be sold. This results in reduced yield efficiencies, increased food waste and diminished financial returns.

To overcome the issues caused by the presence of GM corn in organic corn, systems have been developed that employ optical sorting technology. Systems, such as the combination of lasers and cameras developed by TOMRA, can be used to sort products on structural and biological characteristics ensuring modified crops remain isolated from those grown organically.

In addition, the scale for potential cross-contamination extends beyond savoury foods and into confectionary. Vitamin enhanced gummies are growing in popularity and many manufacturers have different products for adults and children – type A and type B respectively. Due to the varying vitamin dosages found in both, it’s imperative that gummies with a type A dosage do not cross-contaminate any with a type B dosage, as this could invariably lead to children consuming gummies with a vitamin dosage designed for adults.

Fortunately, a trusted combination of camera and laser technology has been developed to ensure these two product types are kept separate. Cameras, used in TOMRA’s Genius optical belt sorter, for example, can make judgements based on color and shape characteristics or structural differences, whilst lasers provide flexibility especially when searching for contaminants invisible to the human eye.

In many walks of life, the phrase “prevention is better than the cure” holds true, and with cross-contamination it couldn’t be more true. Due to the immense number of potential consequences caused by cross-contamination, it is important that food manufacturers, whether they sell nuts, beans, meat or sweets, efficiently identify and isolate contaminants which will improve yields, reduce waste and most importantly minimize the opportunity to cause harm to consumers.

By employing these food sorting technologies, contaminants can be identified on the production line which will reduce the opportunities to cause illness in consumers, in turn, resulting in the reduction of waste caused when products can’t be imported, protect reputations and retain profit margins.

For more information, please visit www.tomra.com/cross-contamination.