Crystallisation at an ideal temperature gives melt-in-your-mouth sensation

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 1 December 2015 | NETZSCH Pumpen & Systeme GmbH | No comments yet

Special chocolate pump enables tempering across whole conveying area…

Statistics tell us that every German citizen eats around 9.5 kg of chocolate a year, in the form of bars, hollow figures, pralines and such like. There is a particularly steep rise in consumption at Easter and Christmas.

The sweet may be very popular, but it is extremely complicated to make. In particular, the temperature has to be precisely controlled at all times to achieve the later melt-in-your-mouth effect. To avoid there being any gap in the processing chain here, NETZSCH Pumpen & Systeme GmbH has now developed a special tempering pump known as the chocolate pump. It is designed to meet the strictest hygiene requirements and is also easy to clean. This means one type of pump can cover a really wide range of tasks in chocolate production.

In order to be able to maintain the required temperature at every stage, the NETZSCH chocolate pump is fitted with a complete heating jacket which can also be controlled segment by segment if need be.

The secret of high-quality chocolate is ensuring that the fat crystals contained in its fats are configured in the best possible way. This is directly dependent on tempering. If the temperature is too high or too low, chocolate will no longer melt in your mouth or will not have an attractive, shiny finish, but a milky, lacklustre look instead. The viscosity also changes along with the crystal content, and this may lead to problems further on in processing or when filling. Tempering is therefore crucial in terms of quality. This means tempered chocolate needs smooth conveyance at a constant temperature.

Controlling the temperature of each pump part independently

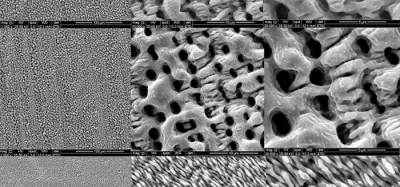

That is why the NEMO® progressing cavity pump, which is characterised by its particularly smooth performance in conveyance, is used as the chocolate pump. It is based on the geometries of a helix rotor and the reverse-helix stator surrounding it, with these being precisely attuned to one another. The sealing line between the two means that sealed conveying chambers are formed with the continuous rotation of the rotor. These allow the medium to move from the inlet to the discharge side at a stable pressure and pulsation-free. The size of the chambers and the low surface speed of the rotor even allow coarser solids, such as nuts or brittle, to be conveyed without any damage being caused.

An adjustable heating jacket has been added to this proven form of pump for tempering. This encloses the whole length of the pump, from the mechanical seals to the pressure ports. It allows the required heat to be kept constant through the various stages of the process. As an option, the complete heating module can also be split into several sections which are controlled separately and can generate different temperatures. This means it is possible for instance to ensure a permanent supply of heat to the mechanical seals, where the fats otherwise often cool down and crystallise.

Simple manual cleaning thanks to quick-clamping connections

Hygiene was the top priority in designing the pump. The coupling rod was therefore incorporated using open pin joints which inhibit product adhesion.

In order to meet high hygiene requirements in the food industry, the pump has been fitted with open pin joints. These are constantly flushed by the medium which inhibits the deposit of product residues. All wetted surfaces have also been given a polished finish and highly-hygienic mechanical seals with no dead spaces have been fitted. The materials used, especially the elastomers, are approved by the FDA and the pumps meet the requirements of the Federal Institute for Risk Assessment (BfR), along with those of the Russian GOST-R. A solution that meets the requirements of chocolate has even been found for the shaft seals, which are a very critical point due to the complex physical characteristics of this medium.

In addition, the pump housing is not screwed onto the drive side. It is instead secured with quick-clamping units, and the end connections are fixed onto the stator with screws that are easy to remove. This makes it possible to disassemble the system quickly and simply – which is all the more practical, as chocolate is incompatible with water and the standard CIP process cannot therefore be used. So that food safety can still be guaranteed and any transfer of allergens between the different production processes can be avoided, it is possible to disassemble the pump easily and clean it by hand.

The NETZSCH chocolate pump comes in various sizes and with a selection of different rotor-stator geometries. Possible capacities range from the smallest amount to 25 m³/h at a maximum pressure of 12 bar. Because the output of progressing cavity pumps is dependent on speed, it is possible to achieve a high level of dosing accuracy. The pump is ideally suited for a wide range of tasks in chocolate production, starting with the supply of raw materials, such as cocoa butter, pure butter fat or nut pastes, and continuing with the pre-mixing of other ingredients such as sugar and milk powder, through to the transport of the tempered, conched mass to the moulding or coating devices. It can also convey fillings or reusable production residues. The robust nature of progressing cavity technology, along with the materials used, ensure a high level of operational reliability and a long service life, even with abrasive components, such as ground granulated sugar or raw cocoa paste.

Compact “Rumba” system, from grinding to conching

Uses of the new conveying system include agitation and emptying tasks, for instance in the innovative “Rumba” system of our sister company, NETZSCH Feinmahltechnik GmbH. This involves a complete compact system that combines grinding and mixing raw materials with conching the chocolate produced as well. A complicated production infrastructure, with separate, mixers, mills and conches, along with the corresponding conveyor belts, thus becomes superfluous to requirements. This saves space and energy and at the same time reduces production costs in comparison to standard processes.