Precise measurement solutions

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 3 November 2020 | NDC Technologies | No comments yet

NDC Technologies’ partner LIMAB UK provides measurement solutions that deliver value to customers.

NDC Technologies has had a long and successful partnership with LIMAB UK Ltd. Specialising in delivering non-contact, in-process measurement solutions, LIMAB is the official distributor of NDC Technologies’ LaserSpeed Pro length and speed gauges and near infrared (NIR) sensors for the UK, Ireland and Benelux regions.

Known for its specialised industry knowledge and applications expertise, LIMAB serves a broad scope of industries including metals, building materials, chemicals, minerals, bulk materials and food processing. The company’s focus is on delivering value to its customers by providing innovative measurement solutions that optimise process efficiency, improve product quality and drive production savings.

In the metals industry, for example, LIMAB UK provides NDC Technologies’ LaserSpeed Pro gauge to precisely control the length and speed of moving products in production applications, such as continuous casting, hot and cold rolling, temper and skin pass mills, pipe and tube, bar and rod, coil and strip. LaserSpeed Pro directly measures the length and speed of products with +/-0.03 percent accuracy. According to NDC Technologies this is the highest in the industry and 20 to 40 times more precise than contact measurement devices. This high level of accuracy enables metal manufacturers to reduce measurement errors, improve process control and realise true production gains.

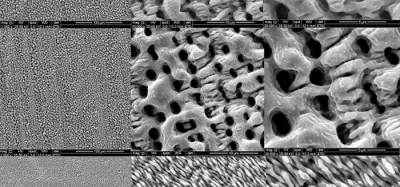

In the food industry, LIMAB UK provides NDC Technologies’ NIR sensors to accurately and consistently measure key constituents such as moisture, fat/oil, protein and degree of bake in a variety of everyday consumable products. Real-time process control allows manufacturers to enhance product quality, reduce waste, increase process productivity and ensure continued brand loyalty. In other applications, NIR sensors are used to accurately measure the moisture in bulk materials, chemicals, pharmaceuticals, paper and converted products. The benefits are multi-fold, enabling manufacturers to improve production efficiency, reduce fossil fuel consumption and achieve right-first-time batch drying.