Potential benefits of micro and nanotechnology for the food industry: does size matter?

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 3 December 2008 | Kathy Groves, Principal Microscopist, Leatherhead Food International | No comments yet

Nanotechnology is an emerging science. Its implementation in the food and drink industry is predicted to grow rapidly due to the benefits it can bring for both industry and the consumer in terms of structure and texture control, health benefits, and safety and quality.

Nanotechnology is an emerging science. Its implementation in the food and drink industry is predicted to grow rapidly due to the benefits it can bring for both industry and the consumer in terms of structure and texture control, health benefits, and safety and quality.

Nanotechnology is an emerging science. Its implementation in the food and drink industry is predicted to grow rapidly due to the benefits it can bring for both industry and the consumer in terms of structure and texture control, health benefits, and safety and quality.

Cientifica reported1 that the biggest sector utilising nanotechnology in 2007 was the chemicals industry, followed by the semi-conductors market. According to Helmut Kaiser Consultancy, the nanofood market has increased from a value of USD 2.6 billion in 2003 to USD 5.3 billion in 2005; and it is expected to soar to USD 20.4 billion in 2015.

Nanotechnology is defined as being related to the design, production or application of structures, devices and systems by controlling the shape and size at the nanometre scale. The term ‘nano’ is derived from a Greek word for dwarf and one nanometre is equivalent to one billionth of a metre. As an example, a human hair is 100,000 nanometres wide, a red blood cell is approximately 7,000 nanometres wide and a typical bacterium is 2,000 nanometres long. The term nanotechnology is usually associated with materials that are less than 100 nanometres in size.

The huge rise in the interest and development of nanotechnology is mainly due to the new and unusual properties of small or nano particles. Thermal, mechanical, magnetic, optical and interfacial properties will change vastly on reduction in the size of particles. These differences in properties compared to the ‘normal’ sized counterparts are mainly due to the increase in the surface area of the particles when they are reduced to nano size. For example, converting a grain of salt into nano particles would increase the surface area by 100,000 times. Solubility also increases dramatically when the size is reduced by so much. For the food and drinks industry, this could have huge benefits in many products and applications.

There are fundamentally two approaches to nanotechnology, which are:

- ‘Top-down’ nanotechnology, which includes starting with larger materials and patterning/‘carving down’ to make nanoscale structures in precise patterns

- ‘Bottom-up’ nanotechnology or molecular nanotechnology (MNT) applies to building organic and inorganic structures atom-by-atom or molecule-by-molecule. The term ‘self-assembly’ is used to describe the forces of nature to assemble nanostructures. The self-assembling properties can be used to control the organisation of material and ideally, this approach is preferred

In reality, many applications are produced top-down, and are micro rather than nano in final size. One micron is 1,000 nanometres. The principle of changes to properties with reducing size is much more pronounced when the size is reduced below 100 nanometres, but for many applications, the reduction to fractions of a micron will have noticeable benefits to properties.

In the non-food sector, there are many applications of nanotechnology currently on the market. Not all involve the presence of individual nanoparticles in the final product as they are often assembled to micron-sized particles for specific reasons, but the properties of the individual nanoparticles are retained.

Examples of nanotechnology in non-food areas include top-class sports equipment made using carbon nanofibres; nanocoatings to machinery to give protection against corrosion and nanofilters to selectively remove toxins. Additional examples include the use of nanotechnology to increase protection in sunscreens; nanoencapsulation for increased benefits in drug delivery for the pharmaceutical sector as well as protection for nutraceuticals, and use of nanotechnology to develop sensors for rapid chemical analysis (lab-on-a-chip or lab-on-a-foil).

The food industry has many areas of potential benefit from micro and nanoscience. In a paper on nanotechnology and food applications, Moraru et al2 (2003) discuss how non-food applications are leading to developments in food areas. They considered that there are four main areas in food applications where micro and nanotechnology can be exploited:

- New functional materials

- Micro and nanoscale processing

- Product development

- Food safety and bio-security

Within these areas, potential applications for the food industry include:

- Antimicrobial coatings and additives: nanosilver is an example of an application currently on the market. Nanosilver is used on some packaging and on first-aid dressings

- Smart packaging: for example incorporation of detectors into packaging that will give information on whether the food inside has deteriorated

- Controlled bioavailability and flavour allows for controlled release of active ingredients

- Improved ingredient functionality

- Rapid assays based on nanosensors

- Improved or novel processes for food manufacture

The area with most potential growth for the food and drinks industry is in improvements in product development and ingredient functionality. Properties of texture, taste and stability are all related to the structure of the food product and the functionality of the ingredients. Indeed, it is important to realise that many natural and processed foods are already organised on the nanoscale and it is in the understanding and control of these micro and nanostructures that will drive the interest and application of nanotechnology to foods.

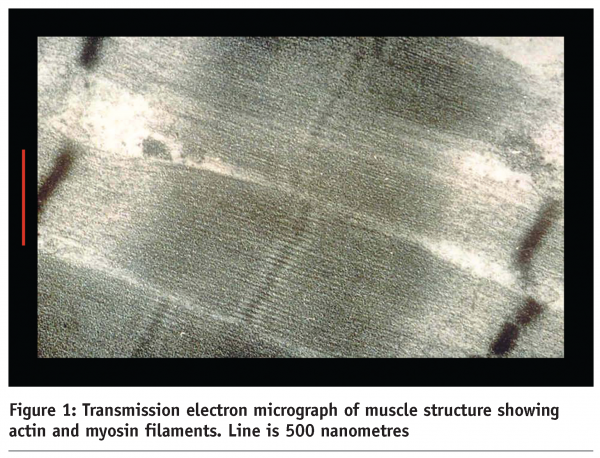

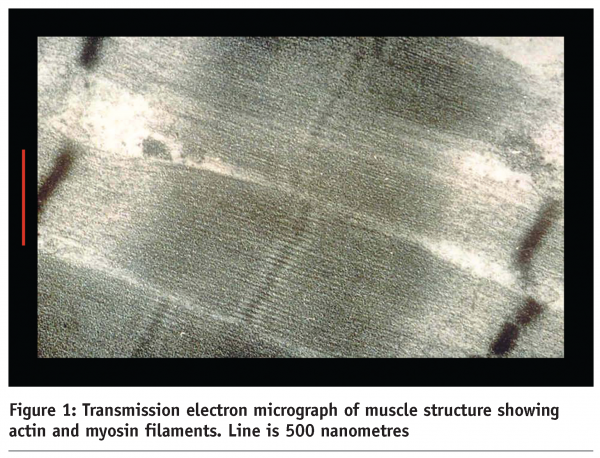

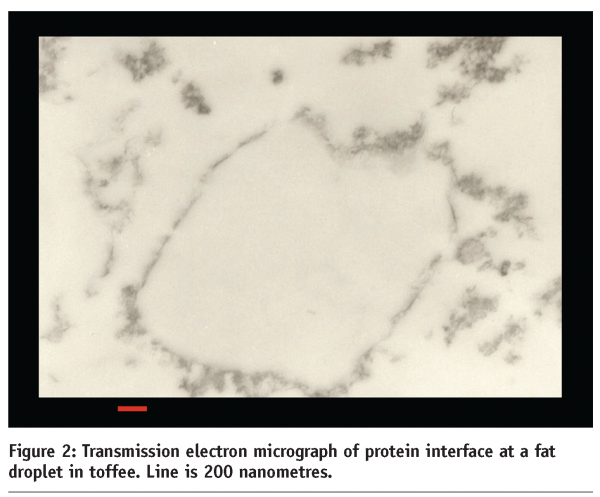

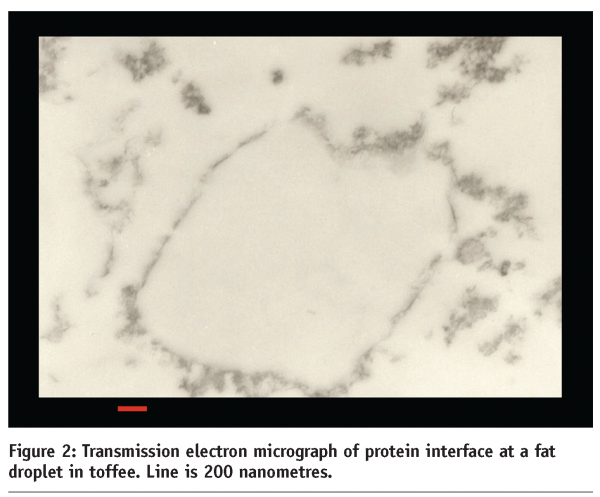

Examples of nanoscale structuring already in place include the structure of meat. Figure 1 shows the fine detail in a muscle cell, where the protein is organised naturally in nanofibres. How these are dispersed in processing (e.g. for ham manufacture) or on cooking will determine the textural properties of the meat. To make a successful vegetarian meat-like product, a product with similar structure needs to be constructed. In another example, in processed food products containing emulsions or air, such as toffees and meringues, the protein stabilising the fat or air is less than 100 nanometres thin (Figure 2). This protein interface is crucial in the stabilisation of the product to give the desired sensory properties. Control of ingredient structures at this level is already taking place to some extent as demonstrated in these examples, and the use of nanotechnology will enhance this.

The use of nanotechnology will benefit consumers as well as the industry by enabling an in-depth understanding of how to control structures within food and drink products to satisfy consumers’ requirements in terms of taste, texture and health benefits. The future scientific thrust will be to deliberately control the size of ingredients or particles in foods or associated materials and make them much smaller. This will move the control of the food properties more towards the nanoscale and utilise the unusual properties known to exist with nanoparticles. This control and understanding could potentially lead to lowering or replacement of some additives, maximising ingredient functionality.

The drivers for the food industry are critical for how nanoscience will develop in this area. These are currently considered to be:

- Food quality & stability

- Health & nutrition

- Food safety

- Sustainability & environmental issues

For food quality and stability, as already discussed, the understanding of how to control the structuring of food and ingredients will lead to better quality products made with fewer additives.

From a health aspect, there are strong drives to lower fat, sugar and salt in foods. These all contribute greatly to the sensory qualities of a food and reducing them tends to give a product that doesn’t have the same desirable qualities. Nanotechnology might allow healthy foods with high-quality sensory attributes.

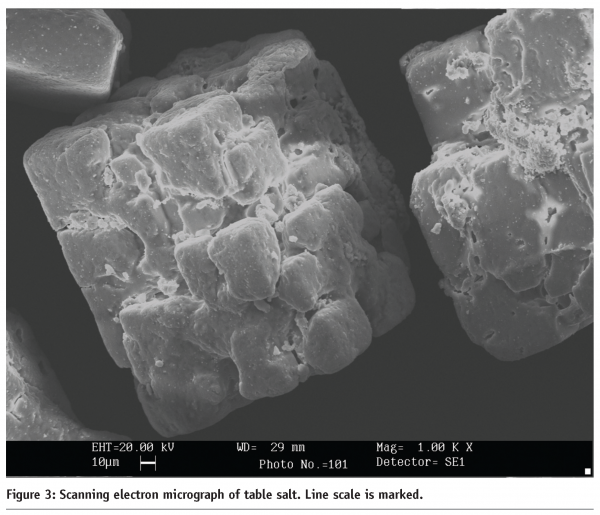

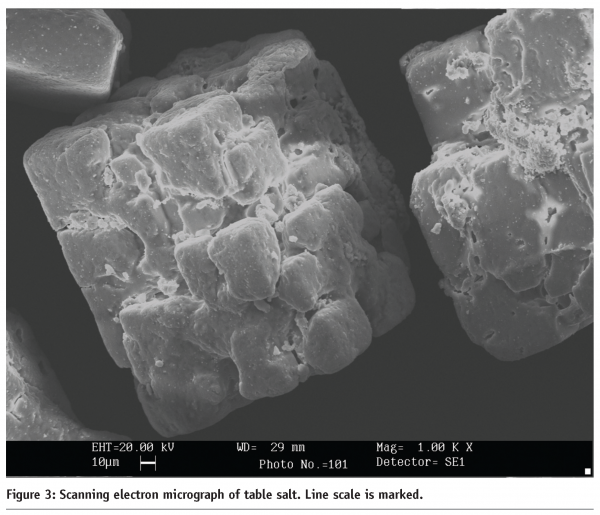

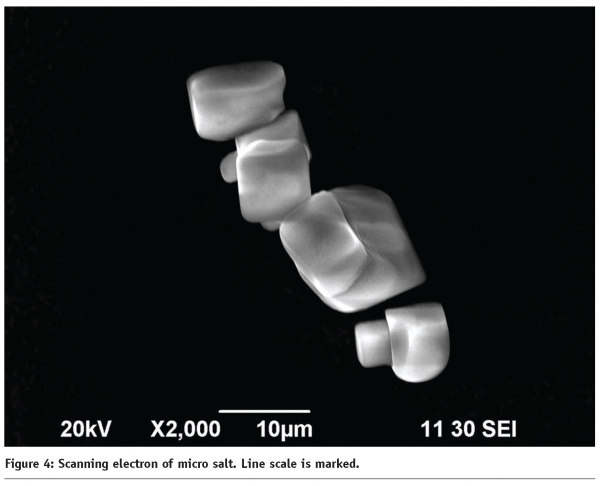

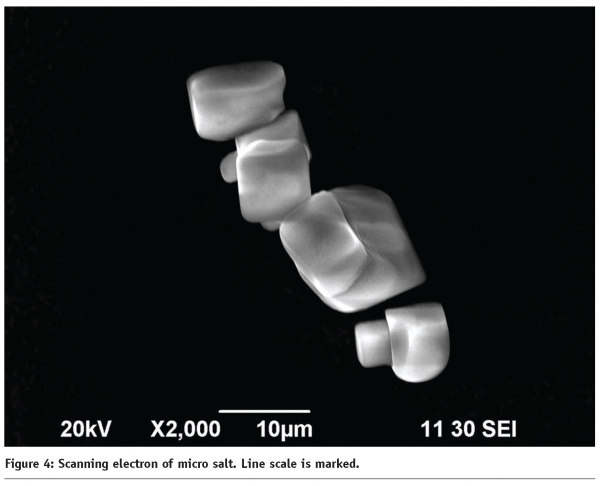

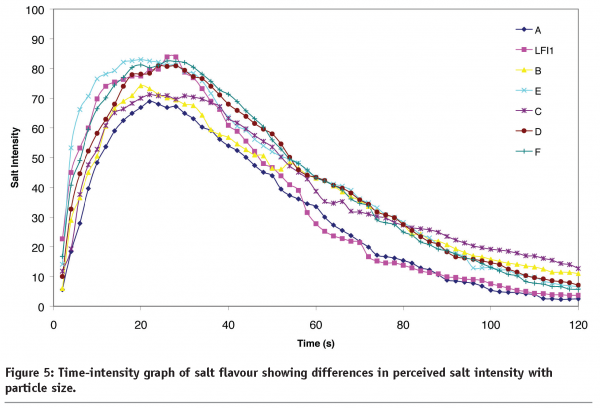

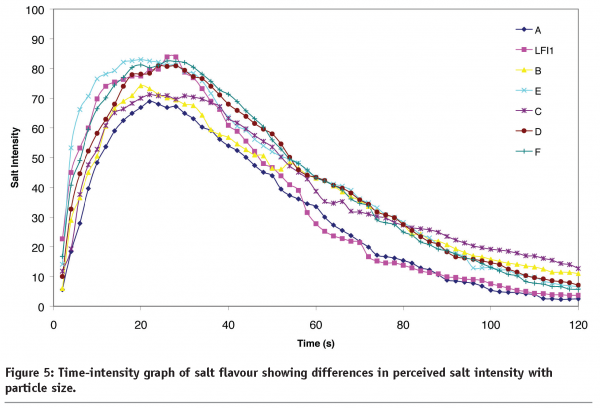

From research carried out by Leatherhead Food International (LFI) on salt reduction (LFI 2005)3, the size of the salt crystals made a difference to the salt flavour impact when tasted by trained panellists. Table-salt particles (Figure 3) are quite large, in the order of hundreds of microns (approximately a quarter of a millimetre). Micro salt (Figure 4 on page 51) with much smaller particles of approximately 5 – 20 microns, but still not nanosize, gave a much more intense initial salt flavour (Figure 5). These results indicate that in food applications with dry salt, it could be that reducing the size of the salt particles will allow less salt to be used.

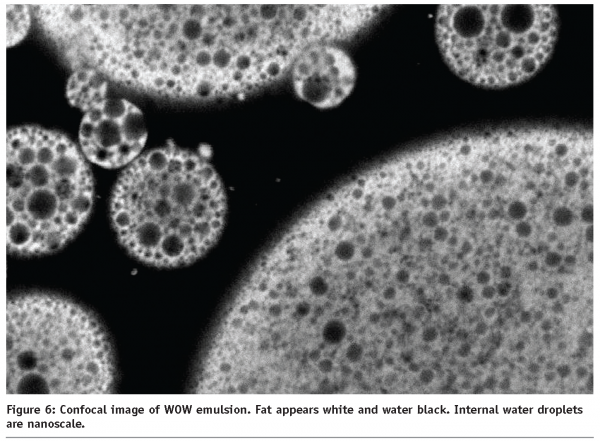

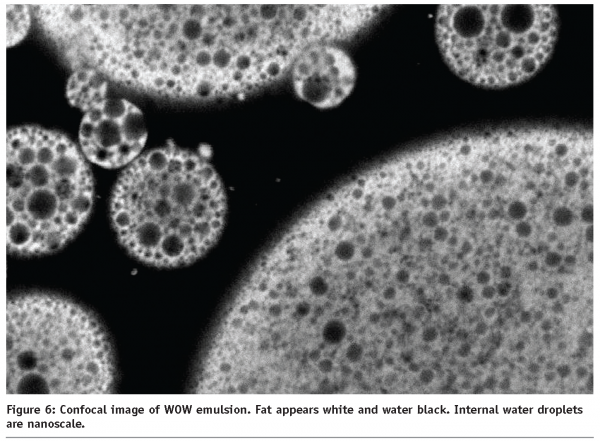

To reduce fat is a challenge since the sensory properties of fat-based foods rely hugely on the fat properties and distribution in the food. Reduced-fat food products just do not taste the same and have a different texture due to the fat replacers used. In a government-industry linked project, research at LFI is looking at fat-based products such as mayonnaises and creams where some of the fat is replaced with water-in-oil-in-water (WOW) emulsions. Mayonnaise and creams are usually composed of fat droplets in a water-based matrix. With the WOW based systems, the fat droplets contain small water droplets encapsulated inside them and these water droplets are at the nano scale. The thinking behind this approach is that the sensory properties of the final food product containing a WOW emulsion should be similar to the full fat based product but the overall fat level is significantly lower. Figure 6 shows an image of the WOW emulsion used in these test products.

Food safety is already addressed by nanotechnology in the areas of antimicrobial packaging and increasingly in the use of novel nano-based surface coatings to reduce bacterial adhesion and growth. As a commercial example of this aspect, MRSA-resistant pyjamas are available from retailers and there are inert nano-based products that can be applied as sprays or coatings to food preparation surfaces to prevent contamination. Outside the food arena, nanotechnology-driven research into sensors is very popular and this will inevitably impact on the food industry in terms of improved sensors for microbiology testing of foods. Another potential benefit in the food safety area is the possibility of developing nano filters or smart filters that can selectively remove allergens from foods.

There are concerns about the potential harmful aspects in nanotechnology and these should be debated openly. In a very detailed report that has been prepared and published by the Royal Society4, these concerns are addressed. This report provides an overview of the potential of nanotechnology in all areas and includes recommendations on the need for risk analysis in the development and use of nanotechnology. Certain areas of the media respond strongly and negatively to the idea that food will be subjected to any nanotechnology process. However, if the consumer is fully aware of the approach being taken and understands that the research will generate more control and understanding in the manufacture of foods, then the benefit to the consumer will be seen clearly.

Nanotechnology has been perceived by both consumers and experts as one of the key technologies that will dominate the twenty first century5. The key questions within this area to be asked and debated are “Who controls the use of nanotechnology?” and “Who benefits from the use of nanotechnology?”

From a food-industry perspective, the key is to identify the challenges for the industry and the benefits to the consumer in terms of a healthier diet, safe foods, reduction in additives, increase in use of natural products, sustainability and environmental concerns. The next step is then to address the science and use it to deliver benefits and solutions. Where nanotechnology can help, then surely it should and will be used.

References

- http://www.cientifica.eu/

- Moraru, C.I.;Panchapakesan, C.P.; Takhistov, P.; Liu, S.; Kokini, J.L. (2003) “Nanotechnology: a new frontier in food science” Food Technology 57 (12), 24-29

- Salt in Processed Foods (2005) Collaborative Research report, Leatherhead Food International

- The Royal Society & The Royal Academy of Engineering (2004) “Nanoscience and nanotechnologies: opportunities and uncertainties” The report and recommendations of the Royal Society & The Royal Academy of Engineering Workshop on Nanotechnology. www.royalsoc.ac.uk

- Siegerst, M., Keller, C., Kastenholz, H., Frey, S and Wiek, A. (2007) “Laypeople’s and Experts’ Perception of Nanotechnology Hazards” Risk Analysis, 27, No. 1, pp. 59 – 69