Membrane emulsification: how to get from basics to business

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 1 June 2009 | Jeroen Willemsen, Manager Business Development, Food Technology Centre, Wageningen UR and Verena Eisner Researcher Separation Technology, Food Technology Centre, Wageningen UR | No comments yet

Consumer expectations of product quality for food emulsions drive the industry to continuously invest in new production methods. Membrane emulsification (ME) has been known for many years and its potential is emphasised in numerous scientific publications. ME is said to ensure highly controlled production of particulates and be a more energy efficient process than conventional methods. Scientific developments in this area cover the production of oil-in-water (O/W) or water-in-oil (W/O) emulsions to multiple emulsions of different types, solid-in-oil-in-water (S/O/W) dispersions, coherent solids (silica particles, solid lipid microspheres) and structured solids (solid lipid microcarriers, gel microbeads).

Modifications of the base technique even extend the capabilities into different membrane materials and operation methods (rotating membrane, oscillating membrane). Nevertheless, the step to industrial applications is not yet fulfilled and appears more difficult than expected.

In this article, the fact that this high potential technique has not yet become a standard method in industrial processes of food products is discussed and specific activities to handle the challenges and hesitations at potential customers are proposed.

Over the past 20 years, there has been a growing interest in a technique for making emulsions known as ‘membrane emulsification’ (ME). Several research institutes all over the world were and are intensively studying the process principle of membrane emulsification (for example, TH Karlsruhe, Wageningen UR, the University of Twente and the University of Leeds).

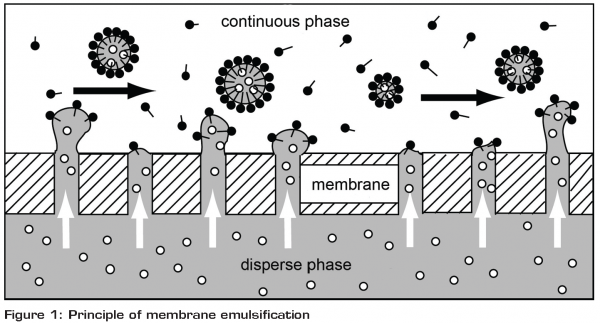

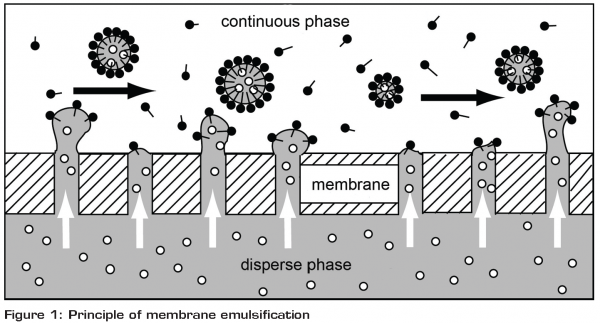

Membrane emulsification may be an elegant solution to avoid the aforementioned disadvantages that occur in a conventional emulsification process. During the production of an emulsion in a cross flow membrane process, the dispersed phase is pressed through the membrane pores to the other side of the membrane (Figure 1). There the droplets are formed on the pore openings and are detached by the continuous phase, which is overflowing the membrane surface. Since no moving parts are involved, the relevant energy dissipation is limited to the pumps, which transport the two phases and have to overcome either the pressure drop along the membrane surface or the transmembrane pressure.

The potential advantages of this technique were detected at an early stage: Low energy input (high efficient energy savings), controlled droplet size and size distribution (more narrow size distribution) and an easy scale-up. After more than 20 years of research, this triggers the question of why this promising method has not yet become a standard technique for industrial applications in food industry. Only a handful of applications in the food area are known. What were and still are the challenges of this promising technique that hamper industrialisation and a real breakthrough? And how to handle them?

Emulsions play an important role in the formations of foods for production of o/w emulsions, for example dressings/sauces, artificial/recombined milks/creams and cream liqueurs, as well as for preparation of some w/o emulsions, for example, margarines and low fat spreads. Some emulsions are products in themselves, such as coffee creamers and cream liqueurs, which are relatively simple emulsions that remain stable towards creaming and coalescence during their production and shelf-life1. Emulsions can also be used as ingredients, which participate in forming the structures of more complex products. This can be yoghurts and other gelled systems or after spray-drying of the emulsion added as encapsulated particles (flavour) into a larger matrix system.

Conventionally, emulsions are produced by using rotor-stator systems, high pressure homogenisers, ultrasound or combinations of these. Although reliable and readily available, these methods require high specific energy input and induce high shear stresses, which may result in coalescence of the dispersed phase. Additionally, the temperature increase cannot be neglected and may influence the properties of the produced emulsion. Both effects may have a negative impact on the properties of the produced emulsions and the final product. One could think about polydispersity, which does not have a negative effect in the production of dressings, but is not acceptable when preparing parental nutrition. Similar limitations apply to high temperatures. A final disadvantage of conventional techniques is that they do not enable the production of stable (i.e. monodispersic) emulsions with larger droplets, e.g. larger than 100mm. This limits the use of emulsion for the development of new products.

Bottlenecks and possible solutions

One of the critical elements for obtaining a uniform droplet size is uniformity of the membrane pores. Unfortunately to date only a few membranes exist, which are fabricated only for emulsification purposes in laboratory scale (e. g. Aquamarijn, SPG). So far, the commercially available membranes potentially applicable for ME are primarily designed for filtration applications2,3. As a result, most membranes are not optimised for uniform pores. Only a few membranes exist, which provide uniform pore shapes and sizes and even less feature a defined pore distance, which is necessary to avoid droplet coalescence on the membrane surface. Using those membranes, experiments in laboratory scale delivered promising results.

Scaling up to industrial scale with high throughputs, often required when dealing with food applications, has failed so far due to the following main reasons:

- Extremely expensive fabrication of perfectly monodisperse membranes at uncertainty of future delivery

- The use of membrane materials, which are not the most favourable material in food industry (e.g. nickel-alloy)

- Limitations especially in the lower droplet size that can be achieved by ME (< 1 µm), as well as their limiting production rate

- Absence of proven applications initiating a ‘race to be second’

- Lack of proper pilot systems to perform upscaling tests and produce samples for sensory or quality studies, revealing the potential of ME in terms of energy efficiency, quality improvement and product innovation

These limiting factors are described below in more detail.

1 + 2

More readily available membranes such as ceramics, although not perfectly monodisperse in pore size, prove to be a more viable alternative, especially for food applications. Contrary to many pharmaceutical, more niche and high value applications, an absolute monodispersity is mostly not required in food industry. Carefully selected and produced ceramic membranes have already proven able to compete with SPG membranes for example, while being less expensive and more easily obtainable.

3

The food industry shows great interest in the production of (uniform) droplets in sizes smaller than one micrometre. One can think of very small uniform oil droplets, which give a more fatty mouthful without increasing or even reducing the total fat content (low fat diet), due to a larger ‘fat’ surface area. Although experiments in laboratory scale by using simple model systems showed that small uniform droplets can be produced, the next step to real systems was up to now not successful. The reasons for the failure are assumed to be in the interaction between the complex emulsion systems and the membrane technique (for example, droplet detachment from hydrophilic / hydrophobic surfaces). At this moment, conventional emulsification methods most often still do better at fulfilling the requirements. The exceptions are products which consist of shear sensitive components (such as proteins).

With respect to the production rate of ME, it is always emphasised that this is not an issue, due to the modular character of this membrane process. Large amounts of modules operating in series and/or parallel may resolve the issue of production rate; this introduces severe process design implications and implies high investing costs. Using membranes with acceptable (i.e. not too low) porosities (higher fluxes) and production costs are required to overcome this challenge; the focus should not all be on delivering the perfect monodispersive emulsion.

4

It is widely acknowledged that emulsions with uniform droplet sizes in the range between 20-200mm have great potential in food production. They can indeed be produced by ME, but no commercial success is known that inspire food industries to invest in the technique. Such emulsions can serve, for example, as microcapsules for flavour. Uniform droplets in this order of magnitude are hard to produce by the conventional emulsification methods, due to the presence of high shear stresses. Especially with higher viscous dispersions, these droplet sizes can almost never be reached.

Also, the production of so-called multiple or double emulsions is expected to be a very lucrative market section for the introduction of membrane emulsification to the food industry. The reason for this expectation is that multiple emulsions are the basis for relatively ‘high’ medium valued products and for new product ideas which are not yet introduced, due to a missing gentle emulsification method. Based on laboratory experiments, it is well known that the production of those types of emulsions is considerably less destructive. While in conventional emulsification methods the inner droplets are easily broken during the production of the outer droplets (caused by high shear stresses), such damage was observed less after the use of membranes4.

5

Pilot facilities enabling ME-long test runs, optimisation and production runs at 50 – 500 litres scales are rare. All those with experience in the upscaling of novel processes acknowledge the occurrence of unexpected challenges, increasing the hesitation to invest in the technique. One of such envisaged challenges is fouling on and in the membrane. Since the disperse phase of the to-be-produced emulsion is pressed through the pores, little particles in complex streams can block the pores easily and reduce the disperse phase flux. Fouling on the membrane surface mainly occurs when high viscous phases are used for the production or reactions between the two phases occur. This observation implies the introduction of proper cleaning (CIP) methods and careful system design.

Yet another is the impact of the process units around the membrane. Pump selection for one is critical when a multi-pass operation mode is chosen, often required to obtain a certain minimal emulsion density. It is known that in some cases the process of ‘pump emulsification’ (i.e. breaking down the emulsion caused by the pump) was the predominant factor determining the emulsion quality, rather than ME.

The food industry is still not convinced of the method of membrane emulsification, which is caused by the above described challenges and limitations. The conventional emulsification methods are robust and well studied for decades and from the industry point of view at the moment techniques, which are more trustworthy. The following concept describes one possible solution to provide a missing link between fundamental research and industrial application for membrane emulsification, which should support the industry in their decision to invest in such a promising technique.

Pilot Unit

Over the past six years, A&F part of Wageningen UR has performed applied research on ME. Different applications in food as well as in non-food areas, small scale and large scale productions and questions about the process parameters and the cleaning procedure span the activities of A&F in the last years.

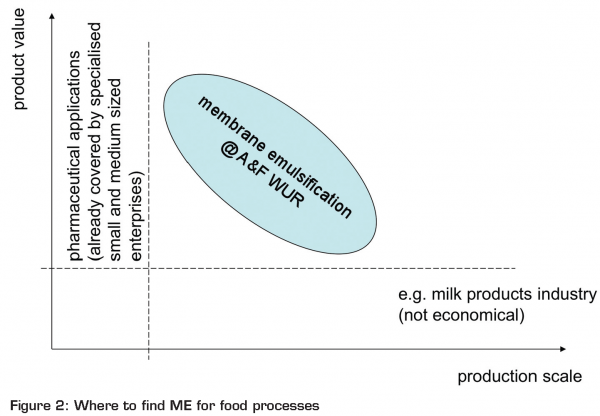

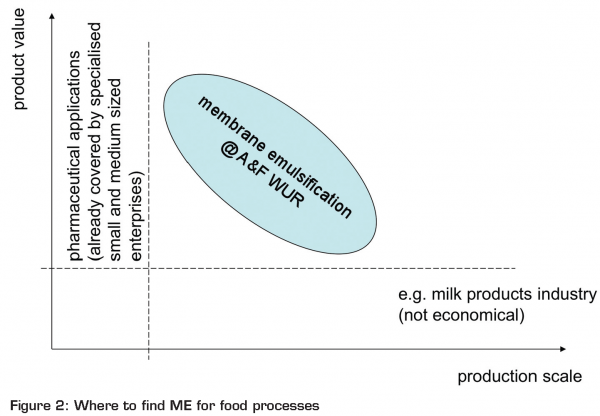

In the short to medium term, it seems as if membrane emulsification is of interest for small up to medium scale production. Large scale production, often found for instance in the milk processing industry, is still difficult to handle for membrane emulsification in terms of performance and product quality. This mainly has to do with available membrane areas and cleaning of them. Furthermore, the values of those products are relatively small, which does not yet fit to the investment and maintenance costs for such a new installation. Small scale production of emulsions, which are for instance often found in pharmaceutical industries and result in high valued products, are already the business of specialised small and medium sized enterprises.

Based on this observation, A&F focuses on the market for medium valued products, which are produced in medium production scales (Figure 2). For this purpose, A&F is realising a mobile pilot unit for membrane emulsification in collaboration with the Dutch ceramic membrane expert company Pervatech BV. The main purpose of this unit is to be more flexible for the most varied requests and at the same moment be prepared for the design of initial orientation experiments. This unit can either be run in the pilot plant of A&F or if necessary transferred to the facilities of the client. Ceramic membranes were chosen since they are expected to provide the required balance between performance and availability.

One big challenge for the use of ME devices is handling the cleaning procedure. The success of a ME process strongly depends on the thoroughness of cleaning procedure. Using a sintered ceramic membrane with a high porous pore mesh for instance asks for a proper cleaning. Cleaning detergents need to be carefully selected to avoid damage of the membrane (for example, coating of the surface). When the cleaning procedure is completed, the operator needs to be sure that no surfactants are left in the system (especially in porous membrane meshwork), since those residues have a significant influence on the following emulsification production. This challenge is well known, but rarely integrated up to now in system design, although it is an important issue for the industry. Beside the removal of product residues, one has also to think of microbiological contamination.

In addition to the answers to technological questions, economical answers also need to be provided. Is it possible to reduce run time, when instead of five cycles only one cycle is necessary by using membrane emulsification? Can the failure of product be reduced, when fewer cycles are necessary? Does the gentle production of the emulsion also mean that the lifetime of the setup is higher (less abrasion)?

Conclusion

Membrane emulsification is still a hot topic for food applications, especially for the production of medium valued components at medium scale. To accelerate the acceptance of the technique in the food industry, A&F develops a flexible pilot system. Test results can be used by the industry to clarify whether value can be added to their products when membrane emulsification is used. It offers an attractive tool as a link between science and application.

References

- Charcosset, C.: Preparation of emulsions and particles by membrane emulsification for the food processing industry, J. Food Engineering, 92,3:241 – 249, 2009

- Gijsbertsen-Abrahamse, A: Membrane Emulsification: Process Principles, PhD thesis, University of Wageningen, 2003

- Joscelyne, S. M. and Tragardh, G.: Membrane Emulsification – a literature review. J. Membrane Sci., 169: 107 – 117, 2000

- V. Eisner, Emulsion Processing with a Rotating Membrane (ROME), PhD thesis, ETH Zurich, 2007

Issue

Related topics

Membrane emulsification, New product development (NPD), Quality analysis & quality control (QA/QC)