DRIED PASTA: A global food

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 15 December 2010 | Maria Ambrogina Pagani, Professor of Cereal Technology, University of Milan | No comments yet

Pasta, the Italian food par excellence, is one of the most interesting products obtained from wheat. Dried pasta has a long shelf-life before being cooked, thanks to its low water content and highly compact texture. Its macromolecules have exceptional hydrating capacities which enable it to increase its weight two-fold and acquire a palatable structure when cooked in boiling water while maintaining a high structural compactness. This property allows starch to be slowly digested, thus ensuring the product a low Glycemix Index despite its high carbohydrate content1. Pasta can then be combined in many different kinds of sauces to suit every taste and to remedy the deficiency of wheat regarding some essential amino-acids.

Pasta, the Italian food par excellence, is one of the most interesting products obtained from wheat. Dried pasta has a long shelf-life before being cooked, thanks to its low water content and highly compact texture. Its macromolecules have exceptional hydrating capacities which enable it to increase its weight two-fold and acquire a palatable structure when cooked in boiling water while maintaining a high structural compactness. This property allows starch to be slowly digested, thus ensuring the product a low Glycemix Index despite its high carbohydrate content1. Pasta can then be combined in many different kinds of sauces to suit every taste and to remedy the deficiency of wheat regarding some essential amino-acids.

Pasta, the Italian food par excellence, is one of the most interesting products obtained from wheat. Dried pasta has a long shelf-life before being cooked, thanks to its low water content and highly compact texture. Its macromolecules have exceptional hydrating capacities which enable it to increase its weight two-fold and acquire a palatable structure when cooked in boiling water while maintaining a high structural compactness. This property allows starch to be slowly digested, thus ensuring the product a low Glycemix Index despite its high carbohydrate content1. Pasta can then be combined in many different kinds of sauces to suit every taste and to remedy the deficiency of wheat regarding some essential amino-acids.

The reasons for the success and worldwide diffusion of pasta also lie in the possibility of using other kinds of cereals, not just durum wheat, in its production. Even in the Mediterranean countries, pasta products enriched in legume flours and cereal or pseudocereal meals are increasingly popular as an interesting and cheap source of fibre and other functional components. In any case, the ingredients and technological processes required for pasta production are extremely simple. Today, pasta is a product that represents globalisation very well, since this product comprises the traditional and typically Italian dried pasta made of semolina, with or without eggs, as well as the oriental pasta made of rice or leguminous flour.

Quality characteristics

Dried pasta is without doubt Italy’s favourite kind of pasta, as demonstrated by the high annual consumption of approximately 28 kilograms per capita/year. The most suitable raw material used for the production of dried pasta is durum wheat semolina, which differs in many ways from common wheat flour, mainly for the rheological properties of its proteins and the high pigment content. These properties in turn reflect the influence of the genotype and the cultivation environment2; in fact, the protein quality is highly dependent on the environment (locality, year, etc.), while the gluten quality and colour are mainly affected by genotype.

The consumer’s final judgment on pasta quality will surely be based on the appearance of the product in its dry state but, above all, its behaviour when cooked. During cooking, the starch granules and the proteins behave in a completely different manner3. The starch granules swell up rapidly and tend to disperse and in part become soluble; the proteins, on the other hand, become completely insoluble and coagulate (Figure 1). Since these phenomena occur at approximately the same temperatures, the more rapidly the proteins form a compact, non-deformable and continuous network during cooking, the more limited the swelling and solubilisation of starch will be, ensuring a firm consistency and absence of stickiness to the product. Good cooking behaviour, therefore, is positively correlated to a high content of protein in semolina and depends on gluten promptness to reticulate. Nevertheless, nowadays starch properties are also considered critical for cooking quality. In fact, breeding studies have recently selected durum wheat varieties with high amylose content. The high gelatinisation temperatures and, consequently, the low swelling and solubilisation capacity of starch with these characteristics not only ensure a good texture to cooked pasta but also improves nutritional properties of the product due to its higher suitability to form resistant starch4.

Figure 1 Cooked pasta: aspect (upper) and SEM images (bottom) of firm spaghetti (left) and sticky spaghetti (right)

Last but not least, the hygienic and sanitary quality of wheat products is receiving more and more attention. Fusarium head blight is a fungal disease of durum wheat with a strong impact on food safety because of the presence of mycotoxins in infected kernels as deoxynivalenol (DON). These mycotoxins are thermally stable, but during milling, they are mainly collected in bran: the retention of DON in semolina is reduced to approximately 80 per cent of the concentration of wheat and further halved during pasta cooking, due to leaching into cooking water5. In this regard, the debranning process before milling results in a significant reduction of DON concentration in durum wheat kernels, improving the sanitary quality and the refining characteristics of semolina at the same time6.

Production technology

As well as being influenced by the properties of the raw material, pasta quality is also influenced by the conditions applied during the pasta-making process. Semolina is kneaded with water to obtain dough of approximately 30 per cent moisture. The moistened mass has the appearance of irregularly shaped lumps and is extruded through a horizontal cylinder with a worm screw that ensures the movement of the dough and facilitates the interaction of the hydrated proteins and the formation of gluten. This operation is mainly carried out in a vacuum to prevent attenuation of colour caused by pigment oxidation. The compression screw pushes the dough towards the die, a bronze plate with different holes according to the shapes desired, and usually lined with Teflon to obtain a smooth product surface. The low fluidity of the mass accounts for the significant pressure (about 10MPa) developed inside the machine during this phase, and the high friction with increases in temperature, an undesirable effect which can be controlled in part via the cylinder’s water jacket which assures temperatures of 40 – 45°C.

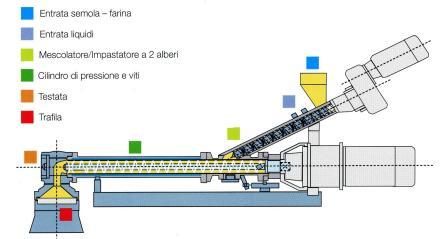

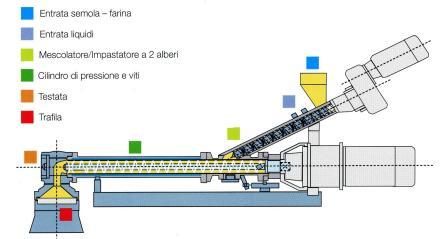

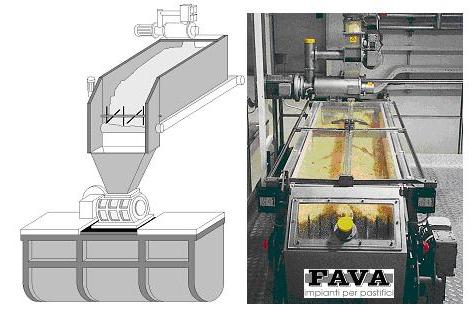

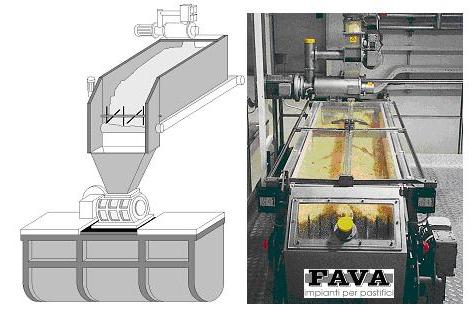

The innovations regarding this first phase of the pasta-making process have focused on the optimisation of the machine’s performance from an engineering point of view7, but have not substantially changed the way the dough is shaped. All the main producers of pasta-making equipment have dedicated special attention to the elimination of one of the most frequent defects of dried semolina pasta, the white specks, due to the presence of unmoistened particles during the mixing, and clearly noticeable in the finished product. This defect not only worsens the aesthetical appearance of the product, but is also associated with a non-homogenous structure of the protein network structure which results in high pasta fragility both in its dry state and during cooking. The appearance of white specks can be reduced by using fine semolina (diameter of the particles < than 300 μm), which have quicker hydration kinetics. Recently, a number of equipment manufacturers have contributed to the optimisation of the mixing and kneading phases with interesting and highly diverse technological configurations. The extrusion press with co-rotating screws developed by Buhler (www.buhlergroup.com) (Figure 2) improves both the productivity and hygienic aspects of the process8. Another alternative is the dough stabilisation belt (Figure 3) proposed by the Italian company Fava (www.fava.it), i.e. a conveyor belt that collects the dough and conveys it to the vacuum mixer and then to the extrusion cylinder. This configuration does not present the double mixer, assuring considerable ease of cleaning and a progressive moistening of the semolina without mechanical stress. Furthermore, the formation of a high ribbon of dough (layer of ca 15 – 20 centimetres height) limits the quantity of oxygen that comes into contact with the mass, preventing the loss of most of the carotenoid pigments. In any case, the pasta extruded from the die reflects the quality characteristics of the raw material used9.

Figure 2: Polimatik® Pasta Press Copyright: Bühler AG, Uzwil, Swisse

Upon extrusion, the fresh pasta has a moisture content of approximately 30 per cent and an aw ~1; consequently, it has a low stability in environmental conditions. Drying has the objective of lowering the moisture content down to 12.5 per cent, preventing the proliferation of microorganisms and reducing numerous enzymatic activities. At the same time, the product acquires its characteristic flavour, aroma and consistency. The drying process has always been, and still is today, the most crucial phase of the entire pasta-making process. Drying the pasta does not only mean evaporating water. Stresses that could occur due to the non-homogenous distribution of water between the surface and internal areas must be avoided. The moisture and volume of the pasta must be reduced uniformly and homogenously. The drying cycle can be divided into phases. During the first pre-drying stage, pasta can lose water very quickly, up to a third of that added during mixing, but the residual moisture (about 18 – 20 per cent) is distributed differently between the dryer surface and the internal part. To prevent the cracking caused by physical stress between these areas, pasta has to rest in high-humidity environments, in order to enable a homogenous distribution of moisture inside the product.

Figure 3 Dough stabilisation belt (nastrino) Copyright: FAVA S.p.A Cento, Italy

The drying cycle included periods of drying or ventilation, alternated with periods of rest, determined by selecting the appropriate hygrometric conditions inside the drying chambers.

Until the 1970s, the maximum temperatures used for the drying cycle were 50 – 55°C (low temperatures, or LT). Under these conditions, over 24 hours were necessary to dry the longer shaped pasta. No significant changes to the properties of the semolina components were noted and the quality during cooking was strictly linked to the quality of the raw material used. Making pasta with excellent semolina was, in those days, the only guarantee for obtaining a product with good cooking properties.

The technological innovations in this context were obviously based on the search for greater cost-saving together with constant product quality. One of the most logical and technologically easiest solutions was to raise the temperature to 70 – 90°C and above (high temperature, or HT)7. These conditions provided a drastic reduction in the processing time (four to eight hours according to the pasta shapes), with consequent significant advantages from the point of view of cost, hygiene and appearance. The improvements in the quality level of the product observed during cooking were unexpected and even surprising at times when considering the characteristics of the raw material. These changes can be attributed to the modifications induced by HT treatment on starch and above all proteins10. In fact, from 70°C proteins coagulate into a structure very similar to the one formed during cooking and are effective in preventing excessive swelling of starch granules, resulting in high firmness and low stickiness in the cooked pasta3. These changes could also decrease protein digestibility10.

Heat damage of dried pasta

The changes attributable to the HT drying diagrams are not, however, all positive. These conditions result in a dullness of taste and excessive browning and, above all, cause heat damage. In a system that contains both proteins and reducing sugars, as in the case of pasta, heat damage is mainly attributed to the Maillard reaction11, a complex reaction with two distinct stages. In the first stage, part of the lysine in the food product is chemically blocked and unavailable from the nutritional point of view.

As well as producing off-colours and off-flavours on pasta, these changes also cause a decrease in the amount of bioavailable lysine (up to 40 per cent of the original amount present in semolina)12, and the appearance of newly-formed compounds13. The intensity of the reaction is controlled by the drying diagram parameters (temperature, time and pasta moisture)14. In particular, the HT cycles, widely used nowadays thanks to the numerous benefits to cooking behaviour as mentioned above, can produce considerable heat damage. Apart from drying, each phase of the pasta-making process before the drying phase is associated with changes that directly or indirectly control the concentration of the molecules involved in the Maillard reaction15. Special significance should be given to the carbohydrate fraction and its quantitative variations. The critical parameters are those that influence the concentration of soluble sugars in extruded pasta: in this regard, the best semolina is characterised by low-amylase activities and minimal mechanical damage of the starch granules during milling. The debranning process (already positively considered for its capacity to decrease potential mycotoxin content of wheat kernels) has to be thought of with great interest due to its capacity to also improve the refining and technological quality of durum wheat semolina16. Future innovations in the pasta sector will have to take these aspects into account.

References

1. Ferro-Luzzi A, Branca F, 1995. Mediterranean diet, Italian style: prototipe of a healthy diet. Am J Clin Nutr, 61 (suppl):1338S-45S

2. Mariani BM, D’Egidio MG, Novaro P, 1995. Durum wheat quality evaluation: influence of genotype and environment. Cereal Chem, 72:194-197

. Resmini P, Pagani MA, 1983. Ultrastructure studies of pasta. A review. Food Microstructure 2:1-12, 98

4. Soh HN, Sisson MJ,Turner M, 2006. Effect of starch granule size distribution and elevated amylase content on durum dough rheology and spaghetti cooking quality. Cereal Chem, 83:513-519

5. Nowicki T W, Gaba DG, Dexter JE, Matsuo RR, Clear RM., 1988. Retention of the Fusarium mycotoxin deoxynivalenol in wheat during processing and cooking of spaghetti and noodles. J. Cereal Sci, 8:189-202

6. Bottega G, Cecchini C, D’Egidio MG, Marti A, Pagani MA, 2009. The debranning process as a tool for improving quality and safety of wheat and wheat products. Tec Molitoria Int, 60 (10/A): 79-88

7. Marchylo BA, Dexter JE, 2001. Pasta production. In Owens G, editor. Cereal processing technology. Boca Raton (FL): CRC Press LLC. p 109-130

8. Dawe PR, Johnston KW, Dintheer W, 2001. Pasta mixing and extrusion. In: Kill RC and Turnbull K, editors. Pasta and semolina technology. Oxford: Blackwell Science LTD. p 86-118

9. Dalbon G, Grivon D, Pagani MA, 1996. Continuous manufacturing process. In: Kruger JE, Matsuo RB, Dick JW, editors. Pasta and noodle technology. St Paul (MN): American Association Cereal Chemists. p 13-58

10. Petitot M, Brossard C, Barron C, Larré C, Morel MH, Micard V, 2009. Modification of pasta structure induced by high drying temperatures. Effects on the in vitro digestibility of protein and starch fractions and the potential allergenicity of protein hydrolysates. Food Chemistry, 116: 401-412

11. International Maillard Reaction Society (IMARS), 2006 http://imars.case.edu

12. Resmini P, Pagani MA, Pellegrino L, 1990. Valutazione del danno termico nella pasta alimentare mediante determinazione per HPLC della ε-furoil-metil-lisina (furosina). Tec Molitoria 41:821-826

13. Resmini P, Pellegrino L, 1994. Occurence of protein-bound lysylpyrrolaldehyde in dried pasta. Cereal Chem 71:254-262

14. Pagani MA, Resmini P, Pellegrino L, 1992. Technological parameters affecting the Maillard reaction in pasta processing. Tecnica Molitoria 43:577-592

15. Pagani MA, De Noni I, Resmini P, Pellegrino L, 1996. Filiera produttiva e danno termico della pasta alimentare secca. Tecnica Molitoria 47:345-361

16. Pagani MA, De Noni I, D’Egidio MG, Cecchini C, 2002. Effectiveness of debranning process of durum wheat for improving semolina quality. Proceedings of the Second International Workshop “Durum Wheat and Pasta Quality: recent achievements and new trends”. Rome, 19-20 November, p 157-161

About the Author

Maria Ambrogina Pagani

Maria Ambrogina Pagani graduated in Food Science and Technology at the University of Milan in 1977. In 2005, she was appointed full professor of Cereal Technology. Her research has been oriented towards understanding the technologically-induced modifications of the relevant macromolecules of cereals in their transformation processes.