The global diversity of distilled spirits

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 14 October 2016 | Paul Hughes, Assistant Professor of Distilling, Oregon State University | No comments yet

Paul Hughes, Assistant Professor of Distilling, Oregon State University gives us an excellent insight into the diffusion and diversity of spirits…

The inception of alcoholic drinks was invariably driven by the availability of local raw materials that could be effectively converted into fermentable substrate. In this way, wine therefore developed in regions where grapes were plentiful – particularly around the Mediterranean Sea – whilst beer made from barley was relatively widespread, being brewed both in Northern Europe and in sunnier climes, reflecting the broad range of climates in which barley can thrive. Fast-forward from the edges of prehistory and, with the increasing movement of agricultural commodities and final products globally, we can see examples of previously regional spirits (e.g. brandies, whiskies) being produced in non-traditional locations. Indeed to protect these various spirit categories, Scotch whisky, French brandies and tequila, in particular, are clearly defined in terms of their production, with regulations also clearly identifying restrictions as to the locations where such products can be made.

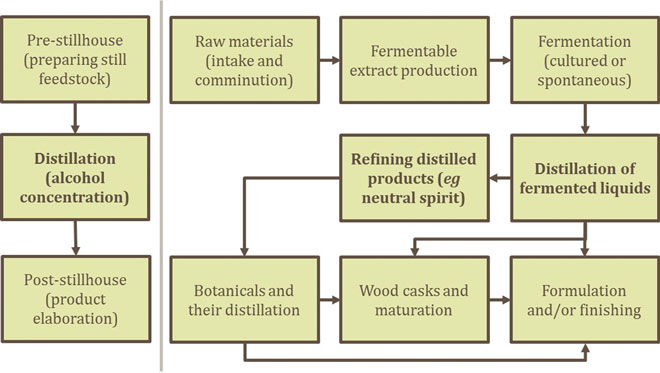

The production of distilled spirit-based drinks can be broken down into three broad operations: the preparation of a fermented extract; distillation; and downstream elaboration (Figure 1). Nevertheless, the diversity of raw materials used and the desired characteristics of the final products mean that there are many process variations across the distilled spirits sector. Here we review the global diversity of distilled spirits and compare and contrast methods of production.

Figure 1: Routes to the production of distilled spirit drinks. Pre-distillation stages are dictated by raw materials required and the micro-organisms used to perform the fermentation, whilst post-distillation, there is considerable diversity depending on the final drinks style and market positioning

Alcohol precursors

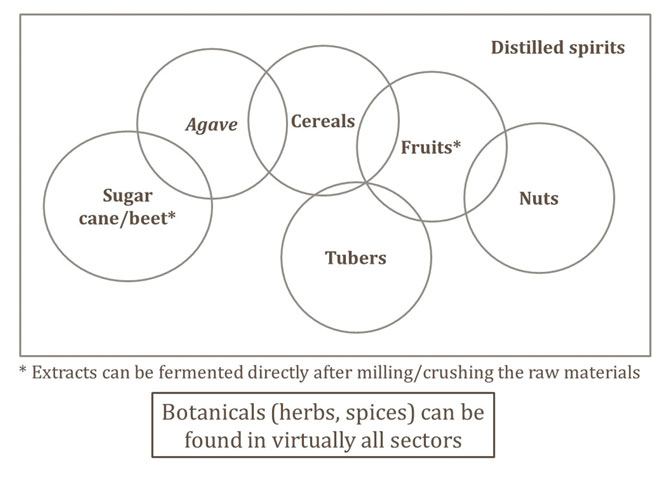

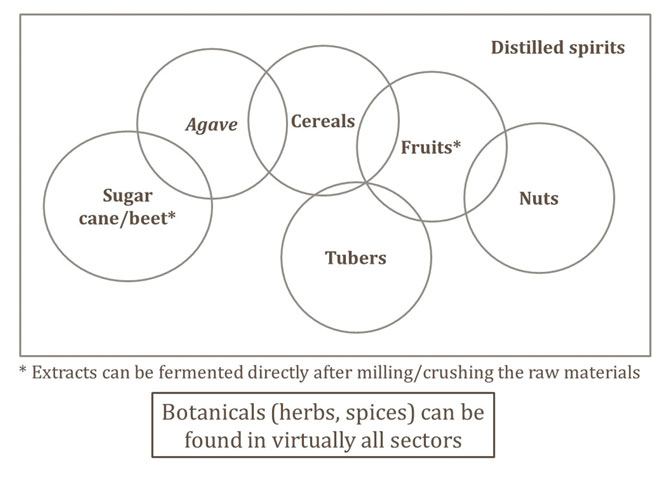

In principle any raw material of agricultural origin that yields a source of fermentable sugars can be fermented and then distilled into a final spirit. This is broadly equivalent to the sugar/carbohydrate-bearing foods that have been consumed for millennia by populations across the globe (Figure 2, page 8). The raw materials used can be classified according to the complexity of the sugars contained. This is useful as most fermentation organisms work much more quickly on simple sugars. Indeed, most yeasts are unable to process complex carbohydrates and so need to be processed to break down complex carbohydrates into simpler, fer – mentable sugars.

The simple sugars are usually sucrose, glucose and fructose, all of which can be assimilated by a broad range of fermentation organisms to produce alcohol. The main complex carbohydrates used for alcohol fermentation are starch and inulin. Starch is made up of polymers of glucose whilst inulin – found principally in Agave for tequila production – is essentially a fructose polymer. So, for these to be effectively converted into alcohol they need to be hydrolysed. In the case of starch, amylase enzymes efficiently reduce starch to a range of simple sugars, including maltose, glucose and maltotriose.

For whiskies and brandies, in particular, strains of Saccharomyces cerevisiae are popular…

These enzymes can be sourced from the raw materials themselves – which is a mandatory requirement, for instance, for the production of Scotch whisky – or added exogenously. Interestingly, during Scotch whisky production the amylase enzymes continue to be active and further degrade residual dextrins, thereby increasing actual alcohol yields. Inulin, the carbohydrate source from Agave used in tequila production, is a little more tractable, and is partially hydrolysed into fructose by heating either in ovens or autoclaves. Additionally, residual fructans (i.e. fructose oligomers), which find use as soluble fibre, can be broken down by certain yeast strains.

Fermentations

Historically fermentations generally relied on infections by local fermentative organisms, allowing for the serendipitous conversion of sugars into alcohol. Even today this so-called spontaneous fermentation approach is still used by some companies to produce products, such as the French Armagnacs and Cognacs, facilitated by the grape-borne microflora, as well as a range of rums, cachaças and tequilas, fermented by plant-borne and adventitious micro-organisms. Whilst this may seem to add an unpredictable element to the fermentation process, in practice the potential variations are less than might be expected, for two reasons. Firstly, the indigenous microflora in and around the production plants and, in the case of sugar cane based fermentations, in the field, should be relatively stable. Secondly, and arguably of more practical significance, is that batches of distillates are often blended, so that variability is evened out to some extent. Nevertheless, it is prudent to check the sensory qualities of fermentations and subsequent distillates for any substantial deviations from the expected flavour performance.

Figure 2: Diversity of raw materials used for the production of distilled spirit drinks. Note that all of the raw materials are of plant origin

The use of cultured organisms for fermentations is preferable where production volumes are larger and to reduce the risk of variability in the time taken for fermentations to complete. There is also a half-way house approach, whereby spontaneous fermentations can be supplemented by cultured yeasts to ensure their timely completion.

The organisms used for spirit production are diverse. For whiskies and brandies, in particular, strains of Saccharomyces cerevisiae are popular; not least for their alcohol tolerance. Certain strains can also tolerate higher temperatures, up to 36°C, which encourages faster fermentations. However, other organisms, such as lactic acid bacteria and even Zymomonas, also play a role in fermentations for distillate production. There are suggestions, though, that some spirit producers need to use antibiotics to suppress bacteria and allow spontaneous yeast fermentations to perform adequately.

Another variable in the fermentation process that provokes discussion is the material of construction for the fermentation vessels themselves. Traditionally constructed from one of various species of wood, many spirit manufacturers have turned to stainless steel instead. The latter does have advantages as it is easier to clean and sterilise, but some distillers are adamant that wooden fermentation vessels are superior, despite the cleaning issues. Indeed, wood is a much better insulator, allowing fermentation temperatures to rise more effectively.

Distillation

The origins of distillation are not clear, but there is evidence to suggest that it has deep roots both in China and the Middle East. Under Paracelsian philosophy, distillation soon became associated with the creation of an elixir, the essence of a crude fermentation. (This notion was also evident in 17th century England where brewers were advised that boiling and evaporative losses from the boil were to be avoided as the essence of the beer was lost).

There are two broad design philosophies of a distillation process, based on batch or continuous processes. The former, often referred to as pot distillation, is generally used for smaller batch distillations. Legislation for Scotch malt whisky, Cognac, mezcal and rhum agricole insist that the spirit is made batch-wise from pot stills. For many other spirits it is up to the spirit distiller whether batch or continuous distillation is used. There is also some blurring at the edges. For instance, a doubler or thumper can be used as a second distillation step, containing the discarded liquids from previous distillations. This is a common approach for bourbon production.

In any case the role of the distillation process is to separate an alcohol-rich liquid from a base fermentation. Generally, the strength of the spirit leaving the still is dependent not only on the original strength of the fermented broth, but also the amount of contact that vapour has with the inside of the still. Introducing vapour restrictions – such as a more convoluted still design or putting plates or baffles into the still – helps to increase the alcohol concentration in the distilled spirits. This refinement also helps to tune out other fermentation flavours, so helping to create a more neutral flavour. Indeed, using columns with a large number of plates can be used to create neutral spirit, required for products such as gin and vodka.

Downstream elaboration

In many cases what exits the still is not exactly what is sold. Rather it requires some form of downstream processing to create the product for sale. This can be as simple as filtration followed by dilution to sales strength before bottling, in the case of, say, the production of some vodkas. The main downstream elaborations applied before finishing (i.e. optional colour adjustment, filtration, dilution and packaging) are maturation, often in the presence of wood, re-distillation with botanicals, maceration with botanicals, compounding and, occasionally, carbon filtration for the removal of minor flavour components from, for example, vodkas.

Most, if not all, world whiskies, brandies and bourbons, require some form of wood maturation. This is mostly done in oak casks, resulting in the uptake of colour and flavour from the cask as well as allowing microoxygenation through the cask wall – all of which enhances the qualities of the spirit. For instance, dimethyl sulfide (DMS) is readily oxidised to DMSO in Scotch whisky, so that after one year it is barely present. Much is rightly made of the importance of the cask to final spirit quality, although how the casks are stored (temperature, humidity, time) all affect the trajectory of maturation. Other spirits, such as cachaça, rums, tequilas and vodkas can be optionally matured. By way of example, reposado, anejo and super anejo tequilas all spend increasing amounts of time maturing in casks, conferring colour on the spirit. However, some (but not all) tequilas classified as ‘gold’ are made by adding caramel to unaged silver or blanco tequilas.

The introduction of botanical flavours into spirits arguably started in the Netherlands, where juniper, considered a panacea for a wide variety of ailments, was added to alcohol to assist in the delivery of the therapeutic effect of the juniper to the patient. Today this has evolved into gin, a broad and quickly diversifying category of spirits, produced with a wide range of botanicals. As it is unaged, the time from production to sale is short, which helps the producer at least in terms of cash-flow. Most legislation requires that gins must be juniper-forward, with the botanical flavours introduced either by compounding or distillation with neutral (that is, colourless and flavour-neutral) spirit. Other botanicals commonly used in gin production include coriander seeds, citrus peels, various roots (e.g. orris, angelica, liquorice) and other herbs and spices such as cassia and cinnamon barks, cardamom and peppercorns. A mere 5-20g of botanicals are all that is required for a litre of gin.

In contrast, absinthes typically require redistillation of neutral spirit with botanicals and, ultimately, some 150g of botanicals per litre of final product are required. The initial spirit distilled with botanicals is then optionally macerated with more botanicals, including the infamous wormwood (Artemisia absinthium) which adds flavour and the characteristic green colouration. For absinthe aficionados, the high oil content in the final product translates into a translucent haze, a phenomenon known as louching, when water is added. It’s worth pointing out that a common sales strength for authentic absinthes is around 74% ABV, so some dilution is recommended. Interestingly, the louched oils seem to form a remarkably stable emulsion.

Many spirit-based drinks are created by compounding, including all liqueurs. Liqueurs are high in sugar (usually > 10% (w/v)), and can be based on essentially any spirit and any flavour. The most popular selling liqueur in the world, Baileys Irish Cream, is compounded not only with sugar but also a substantial amount of cream in its recipe. The scope for producing the next new liqueur is vast, although this category of spirit-based drinks arguably has the most diverse shelf-life issues to contend with.

Enjoying distilled spirit drinks

Many but not all spirit-based drinks are further ‘compounded’ by the consumer, maybe just with ice, or into ‘and’ drinks (e.g. gin-and-tonic), or elaborated further into cocktails. Again this is a clear opportunity for the drinks producer to innovate and, indeed, there is a growing number of self-proclaimed mixologists, creating drinks masterpieces for discerning consumers. In any case, with the growth of craft distilling in many places across the globe we can expect to see an increase in product diversity and inventiveness around aspects of consumer presentation. It’s enough to make one feel very thirsty!

About the author

After a doctorate in chemistry, Paul Hughes worked for the UK government before moving to the Brewing Research Foundation in 1990. Since then he has worked with Heineken, Heriot-Watt University and is now at Oregon State University in the USA to establish a new programme around the theme of distilled spirits.