Impact of mild preservation techniques on packaging

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 23 May 2006 | Iekje Berg, Hetty Jongbloed, Leo van Boxtel, TNO Quality of Life, Zeist | No comments yet

Micro-organisms are the main cause of food spoilage (spoilage organisms) and food-borne diseases (pathogens).Traditional methods to control the growth of micro-organisms include heating (blanching, pasteurisation and sterilisation), freezing and the use of preservative agents. However, consumer demands are changing and they are now asking for fresh, healthy food combined with an extended shelf life. For this reason much work has been carried out in recent years on new (mild) preservation techniques,which can be an alternative for thermal pasteurisation and sterilisation.

Micro-organisms are the main cause of food spoilage (spoilage organisms) and food-borne diseases (pathogens).Traditional methods to control the growth of micro-organisms include heating (blanching, pasteurisation and sterilisation), freezing and the use of preservative agents. However, consumer demands are changing and they are now asking for fresh, healthy food combined with an extended shelf life. For this reason much work has been carried out in recent years on new (mild) preservation techniques,which can be an alternative for thermal pasteurisation and sterilisation.

Micro-organisms are the main cause of food spoilage (spoilage organisms) and food-borne diseases (pathogens).Traditional methods to control the growth of micro-organisms include heating (blanching, pasteurisation and sterilisation), freezing and the use of preservative agents. However, consumer demands are changing and they are now asking for fresh, healthy food combined with an extended shelf life. For this reason much work has been carried out in recent years on new (mild) preservation techniques,which can be an alternative for thermal pasteurisation and sterilisation.

The advantages of mild preservation techniques are that they have less impact on texture, taste, colour and nutrient content than the traditional techniques. Some examples of these preservation techniques are Ultra High Pressure (UHP), Pulsed Electric Fields (PEF), High Intensity Light (HIL), Ultra Violet light (UV) and electron-beam (e-beam) irradiation. However, it is important to study not only the effects of these techniques on the inactivation of micro-organisms, but also the influence on the food product itself and on the packaging material. The reason is that, in many of the new applications, the products will be processed in their packaging.

An important issue in this research is the analysis of chemical changes that occur which can affect the safety, taste and smell of the packed food. Mild preservation treatment can also change the mechanical strength and barrier properties of the food. Therefore TNO have developed an analytical strategy for surveying possible undesirable changes. The formation of degradation products caused by the new preservation processes can now be identified and quantified. The migration from compounds within the packaging materials into the food product can also be measured. In principle this analytical strategy includes all types of products (volatile/non-volatile/polar/apolar). In the first step, the packaging as a whole is analysed to detect major changes in polymers or additives.After that, a concentrated extract of the material is analysed, using techniques such as size exclusion chromatography, gas chromatography and liquid chromatography. This study describes the effects of the preservation techniques UHP, HIL and e-beam irradiation on the packaging materials.

UHP treatment

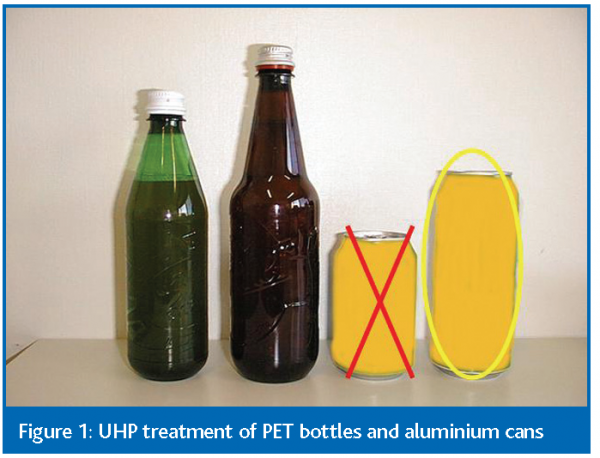

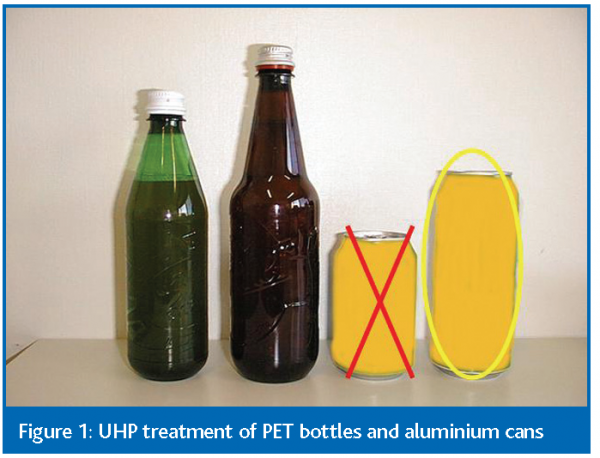

During UHP treatment pressures of 100 to 800 MPa can be used in order to kill vegetative micro-organisms. High pressure treatment results in a slight temperature increase in the product during the pressurisation holding phase, (approximately +2 – + 4 °C per 100 MPa, depending on the food composition) and is due to the so called ‘adiabatic heating’. However, if started at a low temperature (approximately 4°C), they will reach a maximum of approximately 20-40°C during pressure treatment. In either case this is much lower than during thermal preservation processes such as pasteurisation or sterilisation. In this temperature range, many foods will maintain their quality and fresh appearance. However, during UHP treatment the mode of contact between food and packaging material differs from that in a conventional heat treatment. The risk of transferring compounds from the packaging material to the food, which could influence the flavour, taste and safety of the food, should therefore always be analysed. In addition, UHP treatment may also lead to mechanical damage of the packaging material, such as delamination of multilayer materials, deformation of flexible or semi-rigid structure of the packaging containers or package leakage. For UHP treatment of packed products, flexible, or at-least semi-flexible packaging materials are needed. During the pressurisation phase the packaging must sometimes undergo 10-20 per cent volume deformation, depending on the compressibility of the food and the presence of a headspace. Therefore, highly flexible packaging systems such as pouches, vacuum packed pots or trays with a flexible cover are required. Some two piece cans or semi-rigid plastic bottles can also withstand this deformation (Figure 1) under certain preconditions. Tests have been conducted with commercially available packaging materials of varying design, for example soft drink cans, dairy cartons made of laminated cardboard and PET beer bottles. The effect on cans was dependent on the shape, volume and of course the internal head space. It was also dependent on the material; the metal specie used. Taller, small diameter /lean cans showed less damage than shorter and ‘broader’ cans. The effect varied from damaged printing, to dents and leaks. Therefore, it can be concluded that the type of material, the shape and the filling of packages are highly relevant. For laminated cardboard a different effect was seen: delamination of the coating on the surface, probably due to the fact that liquid was entering the film (Figure 2). This effect was seen on the edges, or at places with a small pinhole in the outer film layer.

High Intensity Light or Ultraviolet Light treatment

HIL mimics sunlight, but at 20,000 times its intensity. During HIL treatment, micro-organisms are deactivated by the light. Short, very intense flashes (varying from 1 ms to 100 ms) of a very high light intensity (0.1 to 20 J/cm2) of a broad spectrum white light are responsible for this effect. HIL can be used as a surface decontamination process for both food products and packaging materials. It can also be used to treat the surfaces of food through (UV) transparent packaging materials. Much research was carried out in order to study the effectiveness of HIL and UV in deactivating micro-organisms. However, little is known about the effects on the flavour, taste and texture of the food product. The possible influence of this technique on the safety and functionality of the packaging material is also not yet known.

E-beam irradiation

In e-beam treatment, or electron irradiation, products are bombarded with high-energy electrons, leading to ionisation and other radiolytic reactions as a consequence of collision with molecules. E-beam, but also UHP (more than HIL), allows treatment of foods in closed packaging, minimising the risk of contamination of the food products afterwards. Radiation may result in different chemical reactions, for example, degradation of polymer chains, antioxidants or other additives used for the production of plastic packaging materials. This can result in the formation of new compounds in the packaging material, which might migrate into the packed food. If it is not known what kind of components have been formed as a consequence of treatment, the possibility that the new compounds formed may create problems for food safety cannot be ruled out. In addition, they can cause off-flavours in the packed product and further degradation reactions could affect the physical properties of the packaging material, including barrier properties, strength, flexibility and seal ability. This is the reason why TNO developed the analytical strategy.

Experiments and results

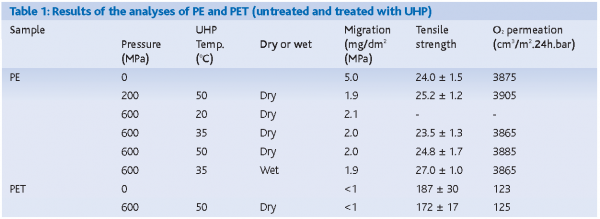

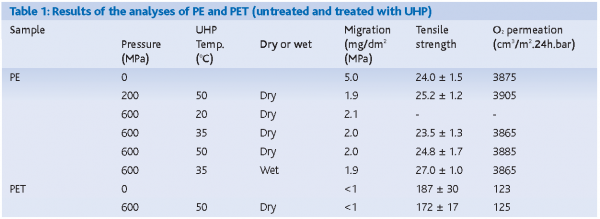

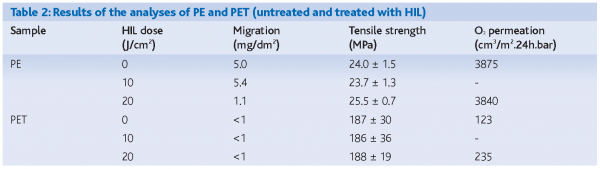

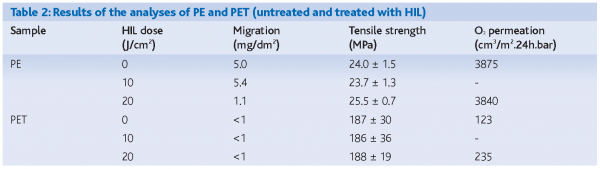

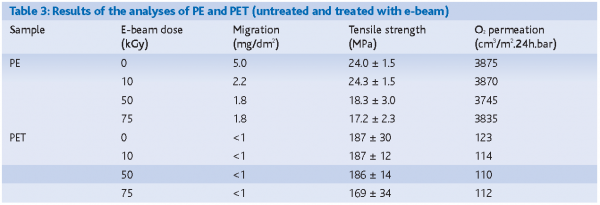

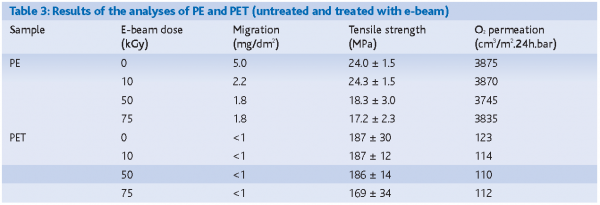

In this study the effects of the preservation techniques (UHP treatment, HIL and e-beam irradiation) on two kinds of packaging materials, namely PE (polyethylene) and PET (polyethylene terephtalate) are described. For this purpose, the materials were exposed to different dose levels of the three preservation techniques (UHP 200-600 MPa; HIL 10-20 J/cm2; e-beam 10-75 kGy). Figure 3 shows the UHP equipment. The important parameters studied were: food safety of the material, possible formation of compounds that influence smell and taste of the packed food and mechanical and physical properties of the packaging material, such as strength and barrier properties. The analyses included the following:

- Migration of compounds from PE and PET to a foodsimulating solvent.A change in migration indicates chemical changes that might endanger food safety

- Formation of volatile compounds, which could influence smell and taste of packed food

- Mechanical strength and barrier properties of PE and PET as important parameters for the functionality of the packaging material during (prolonged) storage

The results of the measurements are shown in Tables 1-3.

Conclusions

The results of this study indicate that the three preservation techniques can influence both PE and PET film properties. E-beam irradiation has the most pronounced effect on polymer materials. The strength of PE decreased following irradiation. PET is much less sensitive to irradiation. HIL and UHP have less pronounced effects on polymer materials like PE and PET. From the results, it can be concluded that much is still unknown about effects of preservation techniques on packaging materials. Further research before the introduction of new technologies to the market will be necessary to guarantee the quality and safety of food packed in materials that have been treated with UHP, HIL or e-beam. Therefore, TNO is elaborating a method of analyses with which any compound migrating from the packaging material into the packed food can be identified. This method and the expertise in packaging legislation, packaging analysis, toxicology and microbiology available within TNO will enable producers to evaluate the safety and suitability of packaging materials for treatment with new (mild) preservation techniques.

References

- Hetty Jongbloed, Leon Coulier. Innovative Issues in Food Packaging. New Food 4, 2002, p. 51-54

- Hetty Jongbloed, Leo van Boxtel, Iekje Berg.Verse voeding in veilige verpakking.Voedingsmiddelentechnologie 34 (2001) 24, p. 10-12,14.

Issue

Related topics

Packaging & Labelling, Quality analysis & quality control (QA/QC)