Antimicrobial surfaces in the food industry

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 23 May 2006 | Dr Terence Child CSci CChem FRSC, Hygiene Consultant | No comments yet

The application of antimicrobial surfaces in the food industry is creating considerable interest in all aspects of food processing operations.The objective of this article is to review and put into perspective the main technologies currently available for applications in this area. Fully embedded systems and surface coated systems will be defined and described, their mode of action explained and the benefits and disadvantages of each type considered.Test methods for evaluating and comparing different technologies will be discussed and indications given of the possible place for antimicrobial coatings in enhanced food hygiene programmes.

The application of antimicrobial surfaces in the food industry is creating considerable interest in all aspects of food processing operations.The objective of this article is to review and put into perspective the main technologies currently available for applications in this area. Fully embedded systems and surface coated systems will be defined and described, their mode of action explained and the benefits and disadvantages of each type considered.Test methods for evaluating and comparing different technologies will be discussed and indications given of the possible place for antimicrobial coatings in enhanced food hygiene programmes.

The application of antimicrobial surfaces in the food industry is creating considerable interest in all aspects of food processing operations.The objective of this article is to review and put into perspective the main technologies currently available for applications in this area. Fully embedded systems and surface coated systems will be defined and described, their mode of action explained and the benefits and disadvantages of each type considered.Test methods for evaluating and comparing different technologies will be discussed and indications given of the possible place for antimicrobial coatings in enhanced food hygiene programmes.

It is important to affirm at the outset that antimicrobial surfaces are not the single solution to food hygiene problems in areas where food is processed or prepared. However, there is a valuable place for antimicrobial surfaces within food hygiene programmes. This article will provide a balanced view of the technologies available, show their essential differences and indicate where successful applications have been made.

Major categories

There are two major categories of antimicrobial surfaces; those resulting from incorporation of the biocide throughout the whole of the item and those with only a surface coating. Examples of totally incorporated biocides would be impregnated materials such as plastics and laminates. Surface coatings can be in the form of paints, or special applications involving spraying, padding or dipping.

Efficacy and durability

Claims are varied with respect to this issue.A disinfection action is claimed by some systems, whereas a biostatic action is maintained by most well-established products on the market. Direct comparison of systems has not been reported in the past because there was no internationally recognised performance standard for evaluating antimicrobial surfaces.An internet review of claims for durability shows a vast range, from seven days to 30 years, depending on the type of product. Paints based on polyurethanes, epoxy materials or styrene acrylics claim, on average, a ten year lifespan.

Application areas

Paints have been used for coating many areas such as walls, ceilings and floors.A variety of biocidal treatments have been used for clothing, kitchen utensils, wall laminates, worktops, chopping boards, baby high chairs and beverage dispensers.

Totally embedded versus surface coated systems

Objects with biocide distributed throughout the body of the material rely on the surface population of biocide to provide the antimicrobial effect. The biocides are tied into the polymer matrix in a complex manner that is not completely understood and some migration can occur within polymer interstices and in the amorphous parts of the matrix. The biocides on the surface are fixed and therefore compliant with food contact approvals. In the event of abrasion or wear over a period of time, a degree of self-repair is possible by exposing more biocidal material from beneath the surface. The biocidal action will therefore remain for the lifetime of the product. The concentration of biocide within the material is an important factor; very high levels will increase the rate of kill but may preclude food contact; levels which are too low may make the surface ineffective or, worse, encourage the growth of resistant strains.

Surface coatings should be of the type where the biocide is fixed on and within a thin polymer film, thus providing a biostatic action. There is no release of biocide and therefore the surface is non-toxic and non-tainting and the surface activity will be constant unless badly soiled.

Other coating products are available that claim a disinfection action by allowing biocides, or combinations of biocides, to leach out of the polymer film onto the surface. Although this provides a more rapid kill rate, the product will be more toxic and is not permissible for food contact.

Performance standards

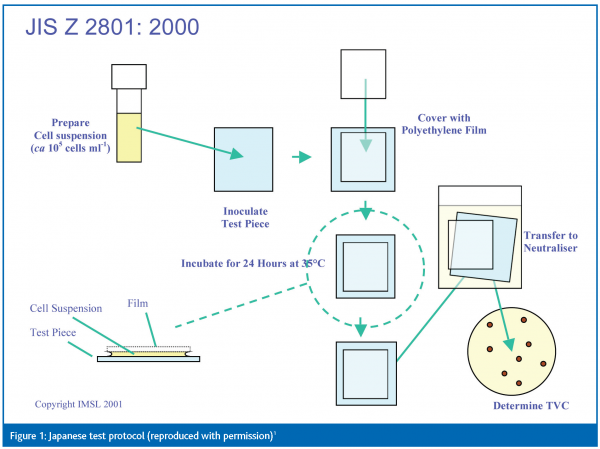

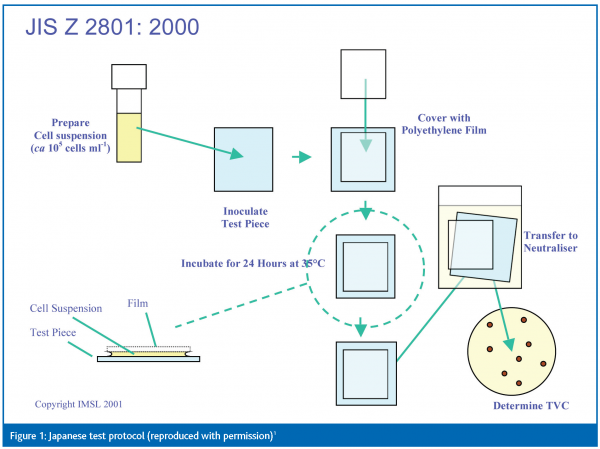

There are no internationally recognised standards for evaluating antimicrobial surfaces, which makes comparison of data difficult or impossible. This has been recognised in the industry and a standard is being formulated through an OECD funded initiative that will provide a definitive test protocol in mid 2006. The test method will be based on a Japanese Industry Standard (JIS Z 2801:2000) and a schematic of the method is indicated in Figure 1. The method involves inoculating a test piece and then covering the area with a polyethylene film. The sandwiched cell suspension is incubated for 24 hours, transferred to a neutraliser and TVC determined in the normal way.

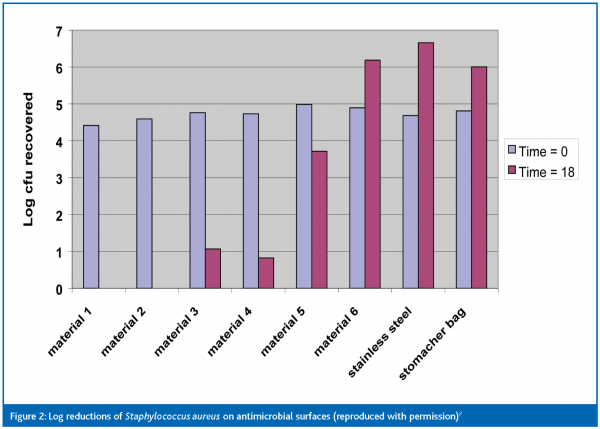

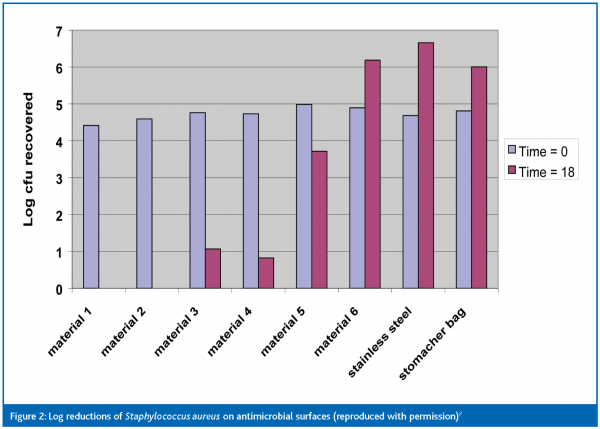

The method has been used to make comparative evaluations of several antimicrobial surfaces. In the results shown below, six different antimicrobial surfaces were inoculated with Staphylococcus aureus. Untreated stainless steel and film from a stomacher bag were included as standards.

Figure 2 illustrates that materials 1 and 2 showed a good disinfection action after 18 hours contact time, and materials 3 and 4 showed reasonable log reductions of 3-4. Materials 5 and 6 were not very effective and material 6 showed behaviour similar to the untreated standards. The method, when finalised, will provide a powerful tool in comparing the effectiveness of antimicrobial surfaces. Later stages of the method development will involve introduction of surface soiling.

Well-established technologies

In selecting technologies for more detailed description, it is important to consider those with a well-established history of applications. These will have undergone extensive safety testing and several new applications will have been developed over the years. Three technologies have been used for a minimum of 20 years; each is different in principle although with some overlap:

- Silver ion technology

- Organic biocides in coatings or incorporated into objects

- Cationic biocide covalently bonded to reactive silicones

Silver ion technology

In its early development, a coating system was formed by binding silver ions to a fine ceramic powder (zeolite), dispersed in a carrier. The ions were then exchanged with sodium, calcium or other ions when the surface came into contact with water. Further developments, particularly in the area of nanotechnology, have enabled the use of silver technology in plastics, fabrics and coatings without the use of zeolite.

Uptake of silver ions by a cell can occur by several mechanisms, including passive diffusion and active transport through systems that usually transport essential ions.While the silver ions may bind non-specifically to cell surfaces, causing disruptions in cellular membrane function, it is widely believed that the antimicrobial properties of silver depend on silver binding within the cell. Once inside the cell, silver ions begin to interrupt critical functions.

Silver ions are highly reactive and readily bind to electron donor groups containing sulphur, oxygen and nitrogen, as well as negatively charged groups such as phosphates and chlorides.A prime target for the silver ions resides in cellular thiol (-SH) groups commonly found in enzymes. The resultant denaturation of the enzymes incapacitates the energy source of the cell and the organism will die.

Applications of silver ion technology

A review of applications shows that this technology has been used in the following areas: treatment of steel ducting and components in HVAC systems, building materials, laminates, floors, walls (in paints), lockers, workwear, sack holders, soap dispensers, keypads and other computer equipment.

Organic biocides

Organic biocides are usually incorporated into plastic and fabrics during the manufacturing stage. For plastics, the biocide is added into the manufacturer’s virgin resin, blended,melted, then moulded or extruded into the final article. For fabrics, the biocide may be incorporated in different ways according to the method of manufacture. The biocide is usually applied by foaming, padding or spraying. The innovative aspect of this technology is the nature of the interaction between the biocide and the polymer or fibre matrix. In plastics, this should provide a fixed population of the active ingredient on the surface of the article, without causing colour changes or, in the case of fabrics where the antimicrobial agent is usually added with a latex binder, without affecting the ‘feel’ of the fabric. The biocide must remain durable and not be washed out during normal laundering.

The concentration of biocide is optimised to provide adequate protection, without the dangers of under- or overdosing. Many different organic biocides are now in use, some specially selected for specific applications.

Applications of organic biocides

There are many applications in the building industry, for example in producing wall laminates for high risk areas in food processing and clean rooms.Other areas of application include work-wear for food processing operatives and catering personnel; tubs for storage and transport of food ingredients; worktops and conveyors; door panels and handles; keyboards and mouse’.

Covalent bonding of biocide to reactive silicone

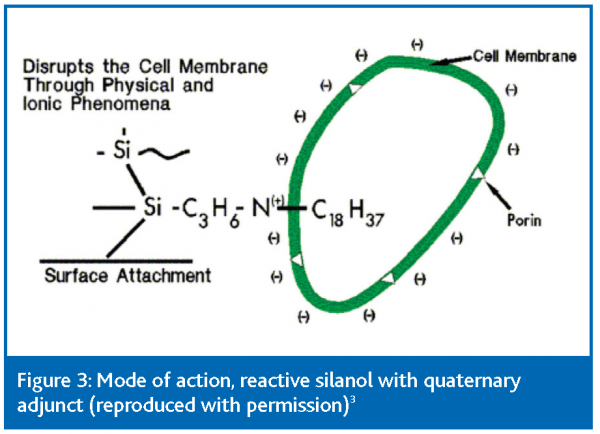

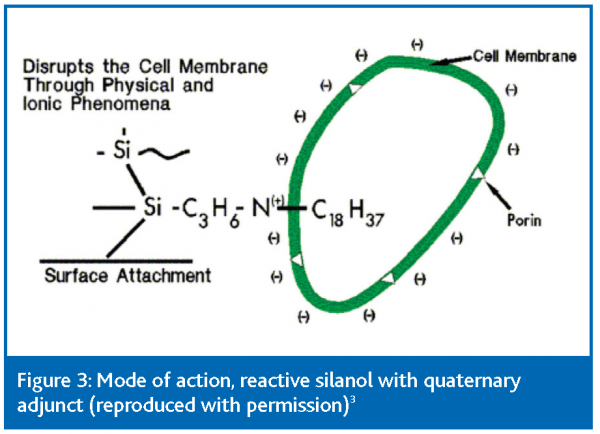

This technology utilises the properties of reactive silanols and their ability to form covalent bonds with a target surface. The silanols are modified with biocidal adjuncts, so that when the silanols fix onto a surface, the active biocidal sites become fixed too. The films created are extremely thin – between 15nm and 180nm – and therefore the original physical properties of the surface are little affected. The mode of action is illustrated in Figure 3.

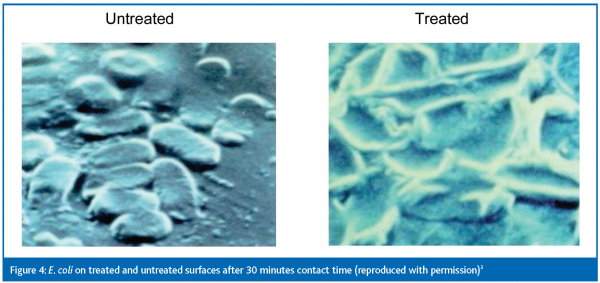

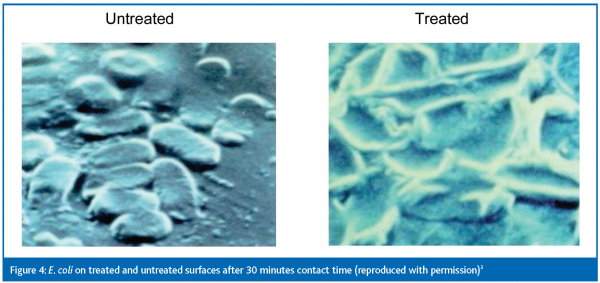

Bacteria arriving on the surface encounter the hydrocarbon portion of the biocidal adjunct, which may be assimilated into the cell without any disruption (Figure 3). However, contact with the positively charged nitrogen atom will unbalance the electrical equilibrium within the cell, particularly inside the porin channels and the outer protein layers, such that the cells can no longer function correctly and cause the organisms to die. This effect is indicated below showing the fate of E. coli on a treated surface. The reactive silanol will form a covalent bond with any surface containing oxygen, nitrogen or carbon. For example, hydroxides or oxides on the surfaces of metals (including stainless steel) will form a durable bond. The application is therefore very versatile and many types of surface may be treated, such as plastic, metal, fabric and painted surfaces.

Applications of biocidal reactive silanols

The fixed nature of the biocide is important where toxicity, taint and other organoleptic aspects are of concern. This is a bacteriostatic surface treatment, not removed by normal cleaning procedures. In fact, it is important to maintain the normal cleaning regime in order to ‘refresh’ the biocidal surface. The technology has been used for treatment of floor and wall materials, air filtration systems and work-wear. The technique has also been used to prevent mould growth on ceiling and wall materials that are susceptible to condensation, such as ripening rooms in cheese processing plants and around the filling area in bottled water plants.

Conclusion

It is important to state that antimicrobial coatings are not a replacement for traditional hygiene procedures. However, they should be considered as a complementary part of standard hygiene programmes.Apart from specialised applications, such as incorporation into fabrics for work-wear, the treatment of large surface areas within food processing plants will reduce the risk of contaminated surfaces acting as a reservoir for organism transfer. The choice of system will be determined by the method of application preferred and the type of location to be treated. Professional advice should be sought. Finally, performance claims should be backed up by an appropriate internationally recognised standard.

Acknowledgements

- Figure 1 is reproduced by kind permission of Peter Askew from Industrial Microbiological Services Ltd

- Figure 2 is from data provided by John Holah and reproduced with permission of Campden & Chorleywood Food Research Association, UK.www.campden.co.uk

- Figures 3 and 4 are reproduced by kind permission of KCM Biogreen 2000 Ltd

Thanks go to KCM Biogreen 2000 Ltd for additional information related to reactive silanol biocides.