Creating an atmosphere for food

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 23 May 2006 | Sabine Paulussen and Dirk Vangeneugden, Materials Technology Department, Flemish Institute for Technological Research, Belgium | No comments yet

The use of polymer films for food packaging has drastically increased during the course of several decades. However, the specifications demanded for these polymer films have increased simultaneously, as well as the pressure surrounding environmental impact and production cost.Today, one of the key challenges is the development of food packaging materials that extend the shelf-life […]

The use of polymer films for food packaging has drastically increased during the course of several decades. However, the specifications demanded for these polymer films have increased simultaneously, as well as the pressure surrounding environmental impact and production cost.Today, one of the key challenges is the development of food packaging materials that extend the shelf-life of their content and in doing so improve food safety.

The packaging industry faces a challenge from the evergrowing demands of consumers, who want foods to remain fresher for longer, as well as being easy to handle, safe, healthy and packaged in environmentally-friendly materials. To meet the need for ready meals and convenience foods without compromising freshness and quality, food packaging is becoming more active.

Recent technological developments have enabled the food industry to create active packaging that prolongs food quality and shelf life.Active packaging interacts with food to reduce oxygen levels, or add flavourings or preservatives. However, additives or food preservatives and flavourings used in or on foodstuffs are subject to authorisation procedures, including scientific evaluation of the substances concerned. Therefore, the future trend is to develop better food packaging technologies in order to reduce the need for food additives. This evolution stimulated the development of anti-microbial and nano-structured barrier coatings for active food packaging applications thereby making use of atmospheric plasma technology.

Atmospheric pressure plasma technology

Low temperature atmospheric pressure plasma treatment by means of dielectric barrier discharges (DBD) constitutes an emerging technology for foil treatment1. The technology is closely related to current industrial corona treatment, which is widely used in foil production and finishing processes2,3. DBD systems have been developed and optimised for the sterilisation and activation of surfaces before printing, gluing or top-coating1,4,5. However, in recent years laboratory and semi industrial scale experiments have demonstrated the interesting capabilities of this technology for in-situ coating deposition6-9. This can be achieved by injection of gaseous or vaporised chemical precursors in the plasma discharge. Unlike low pressure plasma deposition, which generally targets metal oxide or nitride coatings, atmospheric pressure DBD is most suited for deposition of organic and hybrid organic-inorganic coatings. Moreover, atmospheric plasma technology avoids one of the major drawbacks of current low pressure plasma technologies: the need for expensive and limited volume vacuum equipment.

Until recently, the variety of coating precursors used in DBD deposition was limited to gaseous chemicals and liquid precursors with a high vapour pressure and/or high thermal stability that considerably limited the coating capabilities. Furthermore, deposition rates were, in most cases, too low (e.g. 1 μ/h for siloxanes) to meet the requirements for in-line production10. The use of nano-sized aerosols enables us to overcome the latter limitations. It allows us to make use of the full variety of chemical compounds available today and to drastically increase the deposition rates.

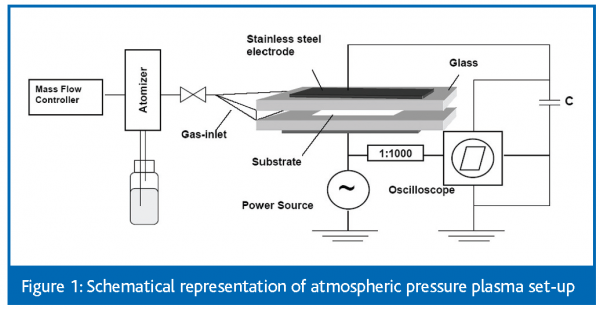

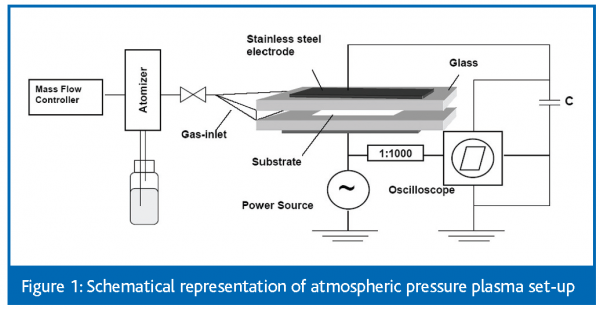

Characteristic of a dielectric barrier discharge set-up is the presence of an insulating layer or dielectric on one or both of the parallel electrodes; the dielectric being either glass, quartz or a ceramic material. In order to ensure stable operation the gap between the electrodes is usually between 0.1 and 10 mm in size and, in most cases, it is limited to 2-3 mm. Typically, dielectric barrier discharges are operated with sinusoidal wave currents, square wave currents or pulsed wave forms with a frequency in the kHz-range. Noble gases are usually used as a carrier gas but in this case nitrogen was chosen, mainly for economical reasons.A schematical representation of a dielectric barrier discharge is shown in Figure 1 while a picture of a pilot scale atmospheric plasma set-up equipped with a roll-on and roll-off unit for in-line treatment of foils is shown in Figure 2.

Barrier coatings

Barrier coating technologies for polymer films can be subdivided roughly into two categories: atmospheric and vacuum based technologies. The atmospheric techniques consist of applying a lacquer followed by a post-curing treatment (thermal, UV or e-beam irradiation).Vacuum coatings mainly concern aluminium metallisation or, when transparency is a requisite, metal oxide (MeOx) deposition. The limitations of these state-of-the-art technologies are related to barrier performance and/or cost and functionality. The values for oxygen transmission rates (OTR) and water vapour transmission rates (WVTR) realised industrially today are 1-3 orders of magnitude higher than targeted for future demanding applications (OTR ~~ WVTR ~~ 10-2)10. Today, only some very specific multilayer combinations of lacquers and MeOx coatings have demonstrated acceptable overall performance10. The complexity of the processes to obtain such a multilayer significantly increases the process costs. Moreover, some films are incompatible with vacuum deposition technology due to out-gassing. Therefore, a novel atmospheric plasma deposition technology that offers better performance and increased functionality at reduced cost was developed. Other advantages of the newly developed technology include the possibility to apply other functional or multifunctional coatings using the same equipment and the fact that the process is environmentally friendly, since no solvents are used.

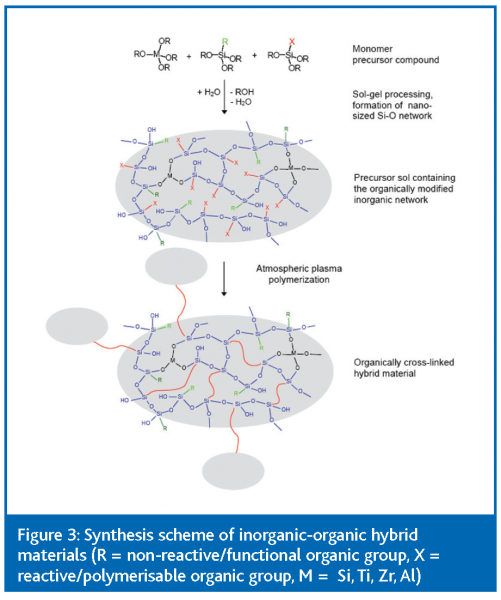

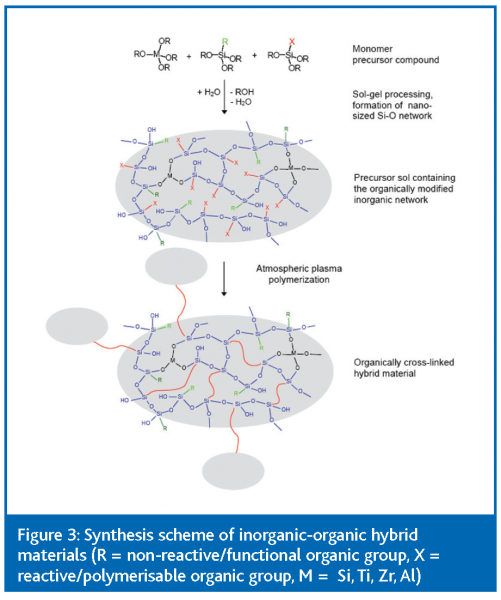

The presented work describes the deposition of hybrid organic-inorganic nano-composite coatings by injection of hybrid precursors and sol-gel systems thereof (ORMOCER®) into the plasma as aerosol particles formed by atomisation. During sol-gel processing, hydrolysis and condensation of organically functionalised alkoxysilanes result in the formation of a nano-sized inorganic pre-polymer bearing some functional groups. The latter can act as an anchor point for the formation of an additional organic network, which may be formed under plasma conditions (Figure 3).

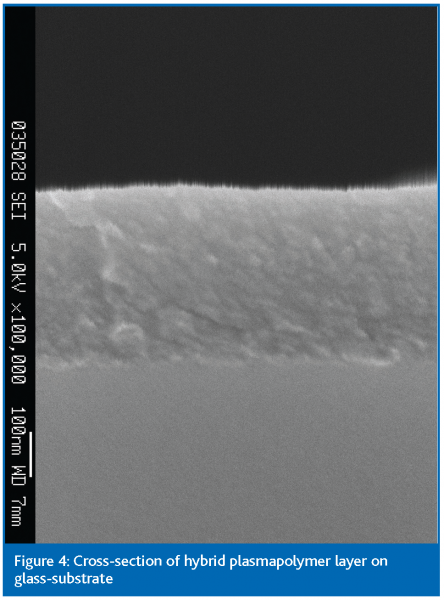

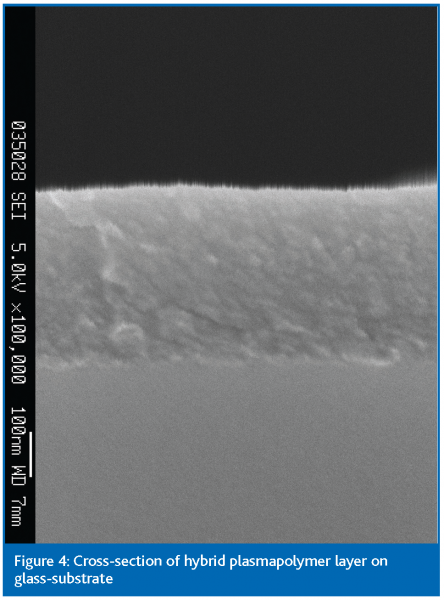

Propyltrimethoxysilane (PTMO) and Bayresit®, which is a high-molecular weight hybrid organic/inorganic cross-linker, and hydrolysed combinations thereof were used as a precursor in the atmospheric pressure plasma process. PET was used as a substrate for barrier-testing. Each of the plasma polymer precursors resulted in smooth, transparent and homogeneous coatings.A picture of a cross-section of the coating obtained from hydrolysed PTMO is shown in Figure 4.

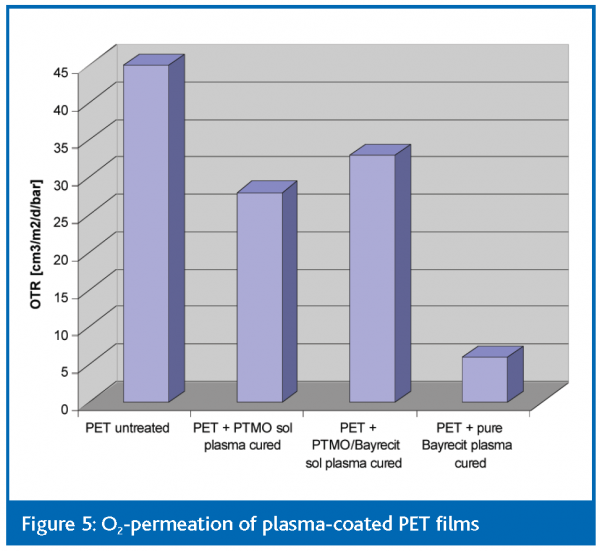

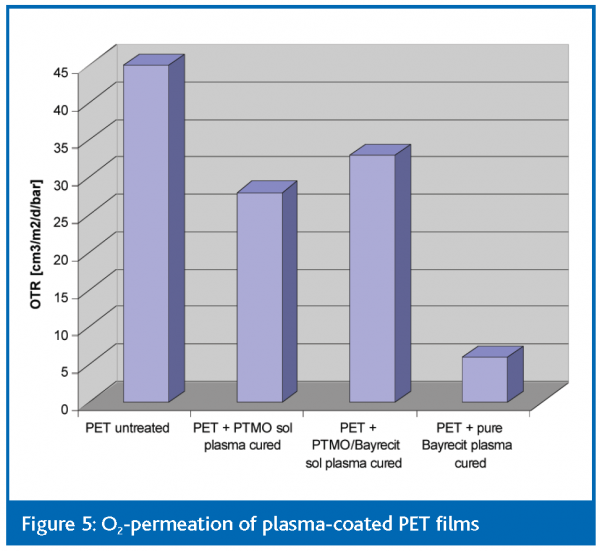

Apparently, plasma coatings obtained from Bayresit® in its pure form gave rise to the lowest oxygen transmission rates (5 cm3 m-2 day-1 bar-1). Compared to the untreated PET, which is a polymer material with relatively high permeability, a tenfold reduction in oxygen transmission rate could be achieved with a coating of approximately one μm thickness (Figure 5).

However, notwithstanding the fact that the values obtained by the newly developed technology are within the range of currently available atmospheric technologies and most commonly used vacuum technology, further optimisation is required. First, the line speed of the process should be increased from a few meters per minute to the industrially targeted speeds of 50 – 100 m/min. This can be accomplished by improvement and up-scaling of the equipment and by optimisation of the sol-gel precursors.

Antimicrobial coatings

Another approach for extending the shelf-life of foodstuffs exists in providing the packaging material with an antibacterial layer.Anti-microbial packaging materials are one of the most promising active food packaging applications. Such coatings can effectively control the microbial contamination of surfaces by inhibiting the growth of micro-organisms on the surface of the food which normally comes into direct contact with the packaging material. However, few commercial products exist today because it is difficult to produce a safe and effective packaging material at reasonable cost.

Therefore, the activation of polypropylene foils in an atmospheric plasma prior to wet-chemical immobilisation of chitosan onto these sheets was investigated here. Chitosan is an edible and biodegradable compound with antimicrobial properties against, for example, bacteria, yeast and moulds11. It is a biopolymer that is prepared from chitin, the second most abundant biopolymer after cellulose. Chitosan was immobilised onto plasma activated BOPP by exploiting glutaraldehyde chemistries. The mechanism is based on the formation of imine bonds between aldehyde groups of glutaraldehyde and amino groups of chitosan and amino activated substrates.

Here, the amount of immobilised chitosan was 1.64 g/m2. The coating solutions without any linking agents as well as the BOPP surfaces without plasma activation treatments were incapable of forming permanent chitosan coatings.

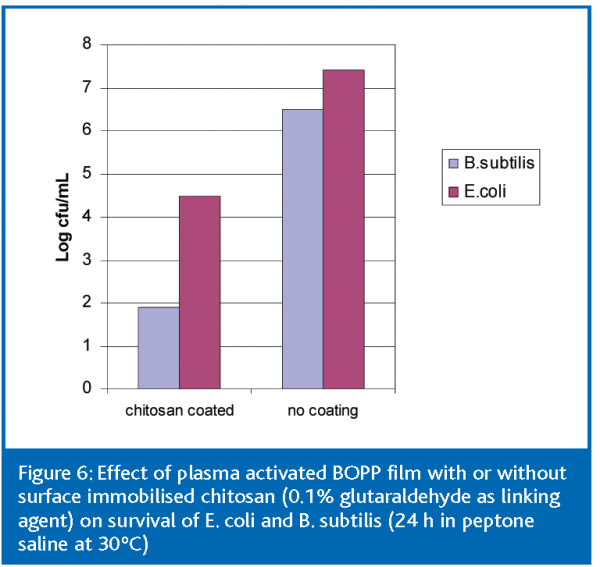

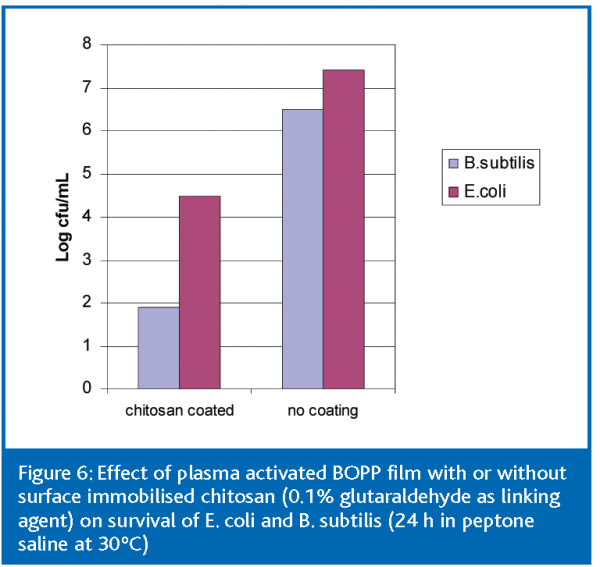

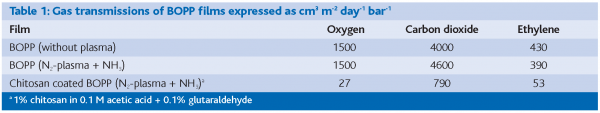

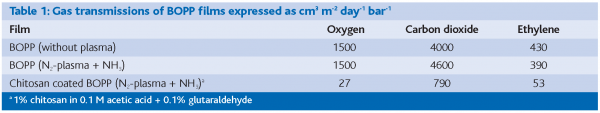

BOPP, like other synthetic polymers, is hydrophobic, whereas the amino functionalised surfaces and especially the cationic polysaccharide structure of chitosan are very hydrophilic. In this case, the addition of glutaraldehyde probably formed a cross-linked chitosan coating, which was only swollen but not dissolved by water absorption. The bonding between chitosan and BOPP was relatively strong and the thickness of the chitosan layer was approximately 2 μm. Surprisingly, oxygen transmission rates fell from 1500 to 27 cm3/ (m2·24 h) after deposition of the chitosan barrier layer. In addition, chitosan formed an effective barrier against both carbon dioxide and ethylene. N2-plasma + NH3 treatment increased the permeability to carbon dioxide as compared with the untreated BOPP (Table 1).

From migration testing it could be concluded that the cross-linked chitosan was permanently immobilised onto BOPP without any notable leaching. The material met the requirements set for the total migration of substances from the packaging materials into foodstuffs as stipulated in Directive 2002/72/EC. Moreover, as chitosan immobilised BOPP films showed strong activity against both Escherichia coli and Bacillus subtilis (Figure 6), they may be exploited in various food packaging applications including antimicrobially active vacuum packages and oxygen barrier films.

Conclusions

It has been demonstrated that atmospheric plasma technology can be applied in different ways for treatment of food packaging materials with the aim of extending the shelf-life of foodstuffs. High-performance, nano-structured, multi-functional barrier coatings on plastic foils were obtained by injecting hybrid precursors into an atmospheric pressure plasma. The barrier properties that could be achieved were within the range of currently available atmospheric technologies and the most commonly used vacuum technology. In addition, the combination of tailored chemical surface activation by means of cold atmospheric plasma treatment and subsequent wet-chemical coating using a chitosan solution resulted in coated plastic foils with good anti-microbial activity and improved barrier properties against oxygen transmission.

Acknowledgements

The work presented was carried out in the framework of SOLPLAS, a project funded by the European Commission under the 5th Framework Program (GRD1-2001-41847). We thank the EC for funding and all partners for the excellent cooperation and their contribution to this work.

References

- Roth J.R., Industrial Plasma Engineering Volume 2 Applications to Nonthermal Plasma Processing. Philadelphia, IOP Publishing, 2001.

- Kogelschatz U., Eliasson B. and Egli W. From ozone generators to flat television screens: history and future potential of dielectric-barrier discharges. Pure And Applied Chemistry 71(10), 1819-1828, 1999.

- Villermet A., Cocolios P., Rames-Langlade G., Coeuret F., Gelot J.L., Prinz E. and Forster F.ALDYNE (TM): surface treatment by atmospheric plasma for plastic films converting industry. Surface & Coatings Technology 174, 899-901, 2003.

- Ben Gadri R., Roth J.R.,Montie T.C., Kelly-Wintenberg K., Tsai P.P.Y., Helfritch D.J., Feldman P., Sherman D.M., Karakaya F. and Chen Z.Y. Sterilization and plasma processing of room temperature surfaces with a one atmosphere uniform glow discharge plasma (OAUGDP). Surface & Coatings Technology 131(1-3), 528-542, 2000.

- Sun C., Zhang D. and Wadsworth L.C. Corona treatment of polyolefin films – A review.Advances In Polymer Technology 18(2), 171-180, 1999.

- Goossens O., Paulussen S.,Vangeneugden D.,Vrielinck H., Callens F., Leys C. and Meneve J. Physical and chemical properties of thin films obtained by plasma polymerisation in a dielectric barrier discharge.New Diamond And Frontier Carbon Technology 13(4), 221-229, 2003.

- Klages C.P., Eichler M. and Thyen R.Atmospheric pressure PA-CVD of silicon- and carbon-based coatings using dielectric barrier discharges.New Diamond And Frontier Carbon Technology 13(4), 175-189, 2003.

- Martin S.,Massines F., Gherardi N. and Jimenez C. Atmospheric pressure PE-CVD of silicon based coatings using a glow dielectric barrier discharge. Surface & Coatings Technology 177, 693-698, 2004.

- Paulussen S., Rego R., Goossens O.,Vangeneugden D. and Rose K. Physical and chemical properties of hybrid barrier coatings obtained in an atmospheric pressure dielectric barrier discharge. Journal Of Physics D-Applied Physics 38(4), 568-575, 2005.

- Leterrier Y. Durability of nanosized oxygen-barrier coatings on polymers – Internal stresses. Progress In Materials Science 48(1), 1-55, 2003.

- Yalpani M., F. J. and Robinson L.E.,Antimicrobial Activity of Some Chitosan Derivatives, in Advances in Chitin and Chitosan, B. C.J., P.A. Sandford, and J.P. Zikakis, Editors. Elsevier Applied Science, London. 543, 1992.