The benefits of Pulse Electric Fields

Posted: 29 April 2020 | Dr Claudia Siemer, Dr Stefan Toepfl | No comments yet

From chips to juices and dried products: New Food discovers how Pulsed Electric Fields (PEF) have been successfully and safely applied to a range of different products in the food and bioprocessing industries.

PEF assisted dried strawberries and dragon fruits

The first reports on Pulsed Electric Fields (PEF) use were published in the 1950s in Ukraine, Moldova and Germany, but it took several decades to transfer the technology into industrial practice. From the 1990s onwards, more than 20 research groups have been identifying underlying mechanisms of action, influencing parameters and potential applications. The first industrial scale systems were developed within public and industrially funded projects at the German Institute of Food Technologies (DIL) where it was successfully introduced into potato processing and the juice industry.

Mechanism of PEF

Application of PEF impacts the cell membranes of any biological cell. Dependent on cell type, field strengths in a range of 1-15kV/cm and energy inputs ranging from less than one up to 150kJ/kg are applied. The high electric field creates an effect termed electroporation.1 This physical effect opens the cell causing a loss of turgor pressure, tissue softening, accelerated mass transfer across the cell wall and low heat microbial inactivation. The use of pulsed fields optimises efficacy and has low energy requirements.

Water and energy savings in French fries industry

In French fry and chip production, PEF has set new standards. The technique replaces previously applied pre-heating and saves up to 90 percent of water and energy. Instead of slowly heating the product up to 60°C, PEF is applied cold, with treatment times below one second. The key benefits of treatment with an intensity of ~ 1kJ/kg are loss of turgor pressure and tissue softening, resulting in a smooth cut during slicing2 or hydro jet cutting (Figure 1). The smooth cut causes less product breakage and feathering, which increases product quality and yield and allows use of different product shapes or raw materials. A smoother product surface also means that less oil – up to 10 percent – enters the product. Today, more than 90 PEF systems with throughputs ranging from 10 to 70t/h are in use in the fries industry worldwide.

Different PEF systems are available on the market, depending on the application of the technology.

Perfect vegetable chips

Figure 1: PEF treated sweet potato string so flexible to be able to tie a knot

Vegetable chips are a popular trend, but producing a consistent high quality chip is often challenging. The application of PEF, however, produces substantial quality improvements throughout the production chain: not only is slicer blade wear reduced but less starch is released into the processing water. PEF users also benefit from a one to two percent yield increase and the quality improvements are diverse; from better crunch to colour improvement (Figure 2) and natural taste of the original vegetable. PEF enables the use of raw materials and shapes that were previously not possible. Accelerated moisture release after PEF allows lower frying temperature in reduced time and therefore retention of natural product colour, as well as a reduced acrylamide formation for products such as sweet potato, carrot, parsnip or beetroot chips.

Premium quality drying

Drying is one of the oldest processes used to inhibit microbial growth and maintain quality of a food product. Usually the process is limited by moisture diffusion. As PEF opens the cell membrane it eliminates that limitation and allows reduction of temperature and shorter times in drying protocols.3 As water can move from product, a core crust formation and product shrinkage are prevented, and for most plant-based products, a drying time reduction of approximately 20 percent is achieved. Reducing the drying temperature causes less detrimental effects on product colour and shape, as well as taste and energy savings. Furthermore, PEF treatment can be applied for any kind of drying technology from conventional air drying to (microwave) vacuum, freeze- or osmotic drying.

PEF enhanced extraction

Figure 2: Comparison of beetroot and carrot chips – untreated vs PEF treated

Many food production operations involve extraction of intracellular substances. The winning of sugar, fruit juices, pigments, colours and oils are but a few examples where PEF-induced cell membrane permeabilisation can be applied to increase extraction yield. In juice production, PEF can be applied to replace high intensity mechanical disintegration or enzymatic maceration. In the sugar industry, a reduced extraction temperature can be applied, and for olive oil processing up to 10 percent yield increase and reduced malaxation times have been observed.4

Drying is one of the oldest processes used to inhibit microbial growth and maintain quality of a food product.

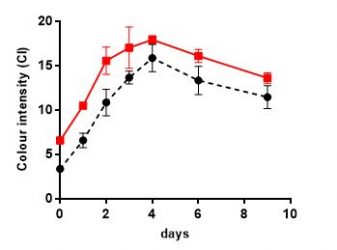

When processing grapes, an enhanced extraction yield of anthocyanins and polyphenols can be seen, allowing a substantial reduction of maceration times and increased production capacity (Figure 3). Dependent on the type of raw material, two different equipment setups can be applied. Pumpable products, such as fruit or vegetable mashes, semisolid products or pre-cut products can be treated in pipe systems with diameters of 50-200mm. Solid products, such as tubers, beets or whole fruits, are usually processed on PEF belt systems.

Peel removal the easy way

Figure 3: Colour intensity of wine Carbernet Sauvignon; red PEF, black no PEF. These results were obtained within a project awarded by the VIDA project and has received funding from the European Union’s Horizon 2020 research and innovation program grant agreement nº 777795

Another effect of PEF is the impact on structural properties of plant material. After a treatment of fruits, kernels or seeds, changes in the elastic properties as well as peel attachment are observed. After a treatment at 2kJ/kg, the tomato peel can be easily removed without any attached tomato flesh, offering a low energy and environmentally-friendly alternative to steam or lye peeling. For nuts and seeds, such as cashews, increased elasticity causes less breakage during shelling and better kernel integrity.

Superior quality juices

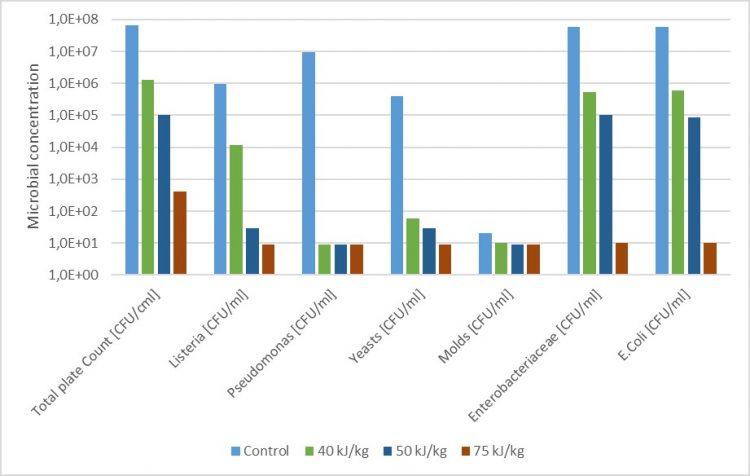

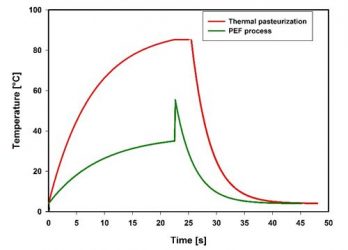

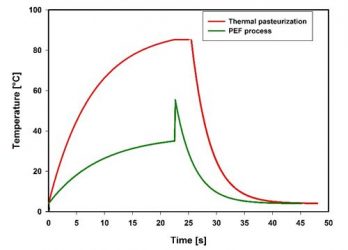

Not only are plant-based cells affected by PEF but so too are microbial cells. This results in microbial inactivation, as it causes a loss of membrane barrier function of yeasts, moulds and bacteria. The microbial load of the juice is reduced (Figure 4) by the treatment of PEF in order to ensure the microbial safety of the juice and to guarantee a certain shelf life. The key advantage over conventional thermal processing is reduced treatment temperature and time (Figure 5). Thus, heat-sensitive colours, nutrients and flavour are not affected. In contrast to other non-thermal processing options, PEF can be operated in a continuous mode and be easily integrated into existing processing lines. Due to its synergism with mild heat, most industrial PEF lines in the juice industry make use of existing or tailored pre-heating and cooling setups, operating at inlet temperatures ranging from 30 to 40°C and maximum product temperatures far below 60°C. The temperature reduction – typically more than one z-value5 – results in premium appearance and taste, compared to a high-temperature, short-time treatment.

Positive effects can also be observed in treating animal cell structure design, such as meat.

The combined approach also allows for recovery of the electrical energy applied and optimum energy efficiency. As PEF is applied to the product before filling, the process is independent of the packaging material applied and can be used for semi-fabricates going into containers, as well as final products bottled in PET or glass. Industrial scale systems range from 500 to 10.000l/h with total processing costs as low as 0.02€/l6 of product in large-scale operations.

Figure 4: Microbial concentration in melon juice before and after PEF treatment at different energy levels using an electric field strength of 12 kV/cm

Use of PEF in meat processing

Positive effects can also be observed in treating animal cell structure design, such as meat. PEF modifies the structure of meat in order to give it a softer texture,7 while the mechanical process of tumbling can produce time reductions. Brine uptake after PEF treatment of meat is approximately 50 percent faster, which increases the effectiveness of the manufacturing process, while also achieving a quality improvement.

PEF systems

Figure 5: Thermal impact of a PEF process versus thermal pasteurization

Different PEF systems are available, depending on the application of the technology. In general, the systems consist of a pulse modulator and a treatment unit. At the early stages of PEF, spark gaps and vacuum tubers were used to power switching.8 However, due to poor durability, high power semiconductors were developed which enabled the design of PEF systems on pilot and industrial scales. Today there are two options for high voltage pulse formation: the first is a transformer-based system, where low voltage pulses are applied in combination with a pulse transformer, and the second is the Marx generator. In this case, a stack of capacitors is charged in parallel and discharged in series to allow a very high-power conversion rate.

The typical average power rate is between 20 and 400kW. The generated high voltage pulses are applied to the product in the treatment unit. Depending on the application, whether it is a liquid or solid food product, the design of the treatment unit varies. For the treatment of liquid material, the treatment zone is integrated in a pipe system, where the diameter varies depending on the throughput required. Solid materials, such as tubers, are conveyed on a belt containing at least two electrodes. For this application, products are submerged in water to improve energy efficiency.

References

1. Saulis G, Wouters PC. (2007). Probable mechanisms of microorganism inactivation by pulsed electric field. In Food preservation by pulsed electric fields – From research to application, 138–151, Woodhead Publishing Limited.

2. Fauster T, Schlossnikl D, Rath F, Ostermeier R, Teufel F, Toepfl S, Jaeger H. (2018). Impact of pulsed electric field (PEF) pretreatment on process performance of industrial French fries production. Journal of Food Engineering, 235, 16-22.

3. Ostermeier R, Giersemehl P, Siemer C, Töpfl S, Jäger H. (2018). Influence of pulsed electric field (PEF) pre-treatment on the convective drying kinetics of onions. Journal of Food Engineering, 237, 110-117.

4. Abenoza M, Benito M, Saldana G, Alvarez I, Raso J, Sanchez-Gimeno AC. (2013). Effects of pulsed electric field on yield extraction and quality of olive oil. Food and Bioprocess Technology, 6, 1367–1373.

5. Heinz V, Toepfl S, Knorr D. (2003) Impact of temperature on lethality and energy efficiency of apple juice pasteurization by pulsed electric fields treatment. Innovative Food Science & Emerging Technologies, Volume 4, Issue 2, 167-175.

6. Toepfl S. (2012) Pulsed electric field food processing – industrial equipment design and commercial applications. Stewart Postharvest Review, 8, 1-7.

7. Kantono K, Hamid N, Oey I, Wang S, Xu Y, Ma Q, Faridnia F, Farouk M. (2019) Physicochemical and sensory properties of beef muscles after Pulsed Electric Field processing. Food Research International, 121,1-11.

8. Sitzmann W, Vorobiev E, Lebovka N. (2017) Pulsed Electric Fields for Food Industry: Historical Overview. In: Miklavčič D. (eds) Handbook of Electroporation. Springer.

About the authors

Related topics

Lab techniques, Plant based, Research & development, Technology & Innovation