The evolution of ice cream technology

Posted: 3 May 2005 | Sabina Burmester, Andrew Russell and Deryck Cebula, Ice Cream Global Technology Centre, Unilever R&D Colworth, U.K. | No comments yet

The process used for commercial ice cream manufacture has changed little in the past 75 years – since the first continuous scraped surface freezer was introduced in the 1930s. In recent years, however, several key technological developments have taken place in the way ice cream is manufactured and these are finding increasing industrial use.

These advances have been largely driven by ‘consumer’ factors such as the desire for healthy products (low fat, low calorie or additive-free), which retain the excellent eating quality associated with ice cream, as well as the continuous need for product innovation to facilitate new interest and differentiation in the market place. In this article, the traditional method of ice cream manufacture is outlined and some of the most significant of the recent process innovations are described.

Conventional processing

Conventional ice cream manufacture comprises a series of operations: mixing, homogenisation, pasteurisation, aeration and freezing. It begins with the mix vessels where the ingredients are heated and dispersed. Once the ingredients are mixed they pass through a valve homogeniser. The high shear forces exerted on the product as it passes through the fine valve at high pressure reduces the fat droplets to a size of around 1μm, producing a homogeneous, stable oil-in-water emulsion. This is subsequently pasteurised and cooled to 5°C using a plate heat exchanger, before being passed to a second storage tank for ‘ageing’, for between 2 and 24 hours. This ageing period is necessary to allow partial crystallisation of the emulsified fat phase, which is important for stabilising the final ice cream structure.

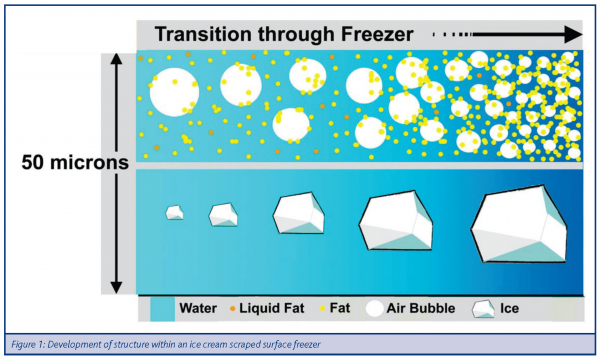

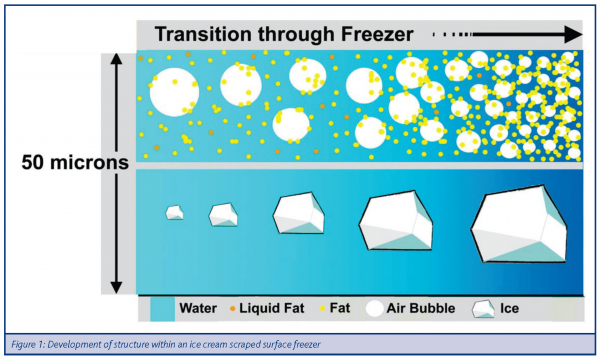

It is in the freezer (a scraped surface heat exchanger) that the distinctive ice cream structure is created. The freezer performs a number of functions: cooling, ice crystallisation, aeration and mixing of the product. Air is introduced into the barrel together with the premix and whipped to form a stable foam by the action of the rotor. The mixture is cooled to around -6°C by the evaporation of liquid ammonia (at -20 to -30°C) in the freezer jacket. Rotor blades continuously scrape the wall of the freezer barrel to prevent build up of frozen material and maintain high heat transfer rates. A typical freezer barrel can process around 1500 l/hr of ice cream. A schematic diagram showing the evolution of ice cream structure within a scraped surface freezer is given in Figure 1.

Once frozen, the ice cream can be shaped or extruded and fruit, nuts or other inclusions can be incorporated; stick and bar products may be coated with chocolate. The completed product is then hardened by cooling to around -25°C in a blast freezer and packaged prior to cold storage and distribution. A large modern factory will produce around 100 million litres of ice cream per annum. More detail on the technical aspects of ice cream and its manufacture can be found in the recent book by Clarke1.

New process technologies

Low temperature extrusion

The temperature at which ice cream becomes sufficiently stable for storage and distribution is around -20ºC. For simplicity of manufacturing it would be ideal if this temperature could be achieved by continuous freezing, to avoid the requirement of the cumbersome hardening step. However, the product outlet temperature from a scraped surface heat exchanger (SSHE) is limited to around -7°C for a typical ice cream formulation. The viscosity of ice cream increases very rapidly as the temperature decreases and for a typical formulation a temperature of -6 to -7ºC represents the viscosity limit for processing in a SSHE. In these devices rotor speeds of up to 250 rotations per minute are used to achieve good air dispersion. At these speeds a large amount of heat is dissipated due to the rotation of the viscous product. Under typical operating conditions, it has been estimated that the frictional heat dissipation is equal to half the heat that is drawn out of the freezer by the refrigerant2. As a result of research into methods for achieving lower temperatures from a continuous freezing device, the low temperature extruder evolved. This is either a single or twin screw extruder that rotates at a speed which is an order of magnitude lower than the SSHE. The screw rotors convey the product through the cooling barrel and consequently dissipate much less frictional heat, allowing cooling of the ice cream mass to temperatures typically between -10°C and -15°C. Low temperature extruders are now available commercially and are typically included as a second freezing step following the SSHE.

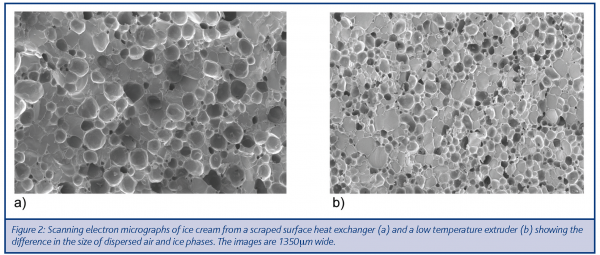

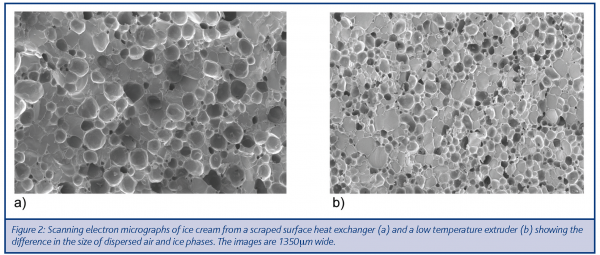

A second and more significant consequence of using low temperature extruders is the effect of working the high viscosity product that occurs within the cooling chamber3. The high shear forces coupled with rapid freezing create a fine microstructure with very small ice crystals and air cells (Figure 2), which increases the perception of creaminess. Low temperature extrusion of ice cream can improve the ice cream quality, compared to that achieved conventionally, or may allow reduction of levels of ingredients such as fat, without loss of quality. In addition, low temperature extrusion allows for shape retention of complex ice cream shapes during processing due to the higher viscosity at the extruder outlet – enabling more sophisticated and innovative product shaping4.

Ultra High Pressure homogenisation

Homogenisation of ice cream mix prior to freezing reduces the size of the fat droplets, increasing the perception of creaminess and the product stability by decreasing the rate of fat agglomeration. The pressure at which ice cream mix is homogenised is a key factor determining the fat droplet size in the ice cream emulsion. To achieve the nominal droplet diameter of 1μm in conventional processing, homogenisation pressures of around 150 bar are used. Recent advances in homogeniser technology have led to the development of ultra high pressure (UHP) homogenisation. Pressures up to 2000 bar have been employed to achieve emulsions with a large number of very small fat droplets (down to 0.3μm diameter). This greatly increases the total surface area per unit volume of the fat droplets and effectively makes better use of the fat present. It has been suggested that by using UHP in ice cream mixes with 5% fat, the ice cream samples obtained have similar textural properties to an 8% fat formulation5. This is an example where a process can be designed to manufacture lower fat, healthier products with similar sensory and stability properties to a product made using a conventional processing route.

Cryogenics

Production of frozen novelties is generally achieved by freezing the product within a mould. For many years the rocket shaped ice lolly was the most complex shape that could be produced in this way. More complex shapes were difficult to achieve due to the high degree of adhesion that exists between a frozen product and the mould surface. This adhesion has been conventionally overcome by heating the mould and melting the outer surface of the product. The cost of heating and re-cooling metal moulds is high and the production rate is reduced. Furthermore, any surface definition on the product is lost. A non-stick surface has been the subject of investigation since the 1940s6 but no suitable coating has yet been found and the adhesive force is high, even with low friction materials. A breakthrough in this area occurred when it was discovered7 that the surface adhesion of a frozen product drops to zero at cryogenic temperatures (i.e. less than -75ºC). This zero adhesion effect is thought to be due to the differential contraction between the product and the metal surface, which breaks the adhesive bond. Zero adhesion technology, which makes use of liquid nitrogen to cool surfaces to the required temperature, is now used commercially for the manufacture of complex three-dimensional products4,6.

Cryogenic fluids, such as liquid nitrogen, are now being applied more widely to achieve innovative product formats, such as small beads of water ice or ice cream8, or softer textures, such as fruit coatings9 (Figure 3). In the latter case, the high freezing rate generated by the direct contact with the extremely cold cryogenic fluid gives rise to formation of very small ice crystals, which have a soft and smooth texture.

Pre-aeration

Ice cream contains up to 60% of air (by volume), which is normally added within the ice cream SSHE. When the aeration process is performed upstream from the freezer using a separate high-shear mixer, improved product properties can be achieved. Pre-aeration of the ice cream mix in this way can have an effect on texture attributes of the final product such as firmness and stiffness10. The small air cells formed have been found to have a significant effect on the perception of creaminess and smoothness and improve the shape retention of the finished ice cream during distribution. An example of the use of pre-aeration in combination with freezing has been developed by WCB in their new ‘low-draw temperature’ system. Improved air cell distribution, melt-down time and storage stability have been claimed.

Conclusions

While process innovations have been slow to arrive in the ice cream business, there is now firm evidence that such developments are critical to the evolution of the industry. This has as much to do with increasing competition within the industry as it has the demands from consumers for higher value and quality in the products they consume. In the past, the barriers to change have been the cost of alternative methods, such as the use of cryogens, or simply the high cost of replacing capital intensive equipment still in use. In the changing worlds of both technology and the consumer, we now see developments beyond the relatively incremental changes that bring reduced cost, to ones that really address the need of consumers. It can be anticipated that this trend will continue, with the impact from new process technologies translating into product innovation. It is expected, however, that technological advances will not be limited to the manufacturing process, but will be increasingly associated with ingredients and their functional behaviour to address consumer need for health and wellness, without sacrificing the quality expected from eating ice cream.

References

- Clarke, C. (2004) The Science of Ice Cream. The Royal Society of Chemistry, Cambridge, UK.

- Hartel, R.W. (1996) Ice crystallisation during the manufacture of ice cream. Trends in Food Science and Technology, 7, 315-321.

- Eisner, M.D., Wildmoser, H., Windhab, E.J. (2005) Air cell microstructuring in a high viscous ice cream matrix, Colloids and Surfaces A: Physiochem. Eng., in press.

- Hansen, P.H. (2004) Shaping the products of the future. Proceedings of the second IDF International Symposium on Ice Cream, Thessaloniki, Greece, 14-16 May, 2003. International Dairy Federation.pp 88-99.

- Hayes, M.G., Lefrancois, A.C., Waldron, D.S., Goff, H.D. and Kelly, A.L. Influence of high pressure homogenisation on some characteristics of ice cream. Milchwissenscaft, 58, 519-523.

- Jones, S.T. (1997) 3D lollies – Zero Adhesion technology is being used to create three dimensional ice cream moulds, Dairy Industries International, 62(1), 31.

- Eek, L., Olsson, L. (1990) Method and arrangement for freezing. Frigoscandia Contracting AB, World patent: WO 9006693.

- Jones, C.D., Jones, S. (2002) Cryogenic Processor for Liquid Feed Preparation of a Free-Flowing Frozen Product, World patent: WO 0206741 A1.

- Carrick, G., Duff, K.J., Houlihan, T,D., Smith, S. (1995) Ice Confections. European patent: EP0710074.

- Tharp, B., Young, S. (2004) Tharp and Young on Ice Cream. Dairy Foods, May, 105(5), 46.