An overview of membrane applications in the dairy industry

Posted: 23 May 2007 | Dr Geneviève Gésan-Guiziou (INRA) | No comments yet

In the last 30 years, membrane processes have become major tools in the food industry.1,2 This industry represents the second sector of membrane applications, after water treatment, and on equal terms with pharmaceutical and biotechnology applications.

In the last 30 years, membrane processes have become major tools in the food industry.1,2 This industry represents the second sector of membrane applications, after water treatment, and on equal terms with pharmaceutical and biotechnology applications.

Among the food sector, the dairy industry has undoubtedly developed the most advanced filtration procedures for concentration and fractionation of molecules from milk and its derivates. The first membrane development in the separation procedures of milk components occurred in the late 1960’s with the advent of membrane separation. This has spawned a new industry for whey treatment as well as new avenues for cheese-making. Since then, the membrane equipments have been implemented throughout the dairy processing chains: milk reception, cheese-making, whey protein concentration, fractionation of protein, effluents treatment. Nowadays, 40 percent of the membrane food applications are developed in the dairy industry.

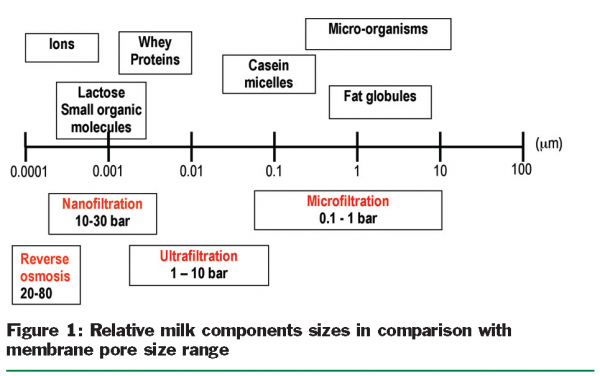

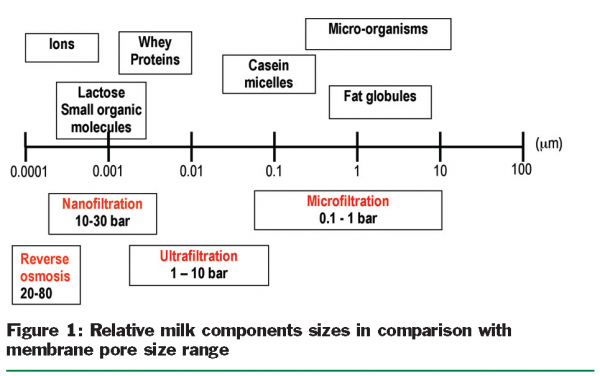

Four different membrane operations are distinguished. (Figure 1) Ultrafiltration is the most widely used process in the dairy industry, with an installed membrane area around 350,000m2. Nanofiltration (100,000m2) has recently been developed for whey demineralisation. The membrane area of reverse osmosis has stabilised (65,000m2) and the microfiltration area is developing due to its capacity to retain micro-organisms or casein micelles (15,000m2 installed).

Microfiltration

The microfiltration (MF) of milk concerns two main industrial applications3:

1.1. Bacteria removal from skimmed milk

Like most food fluids, milk provides a favourable media for spoilage micro-organisms, which can lead to alteration of chemical composition of milk and difficulties in milk preservation and transformation. In that context, MF offers an interesting alternative to heat-treatment or bactofugation3. It is particularly adapted to the bacteria removal from skimmed milk, the size of the micro-organisms being in the same range as fat globules (Figure 1).

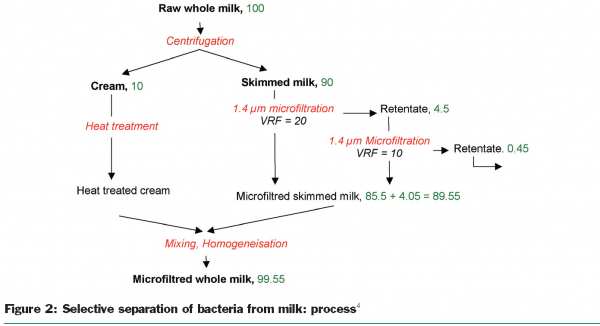

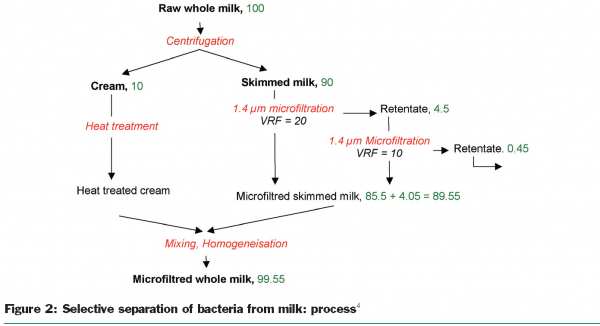

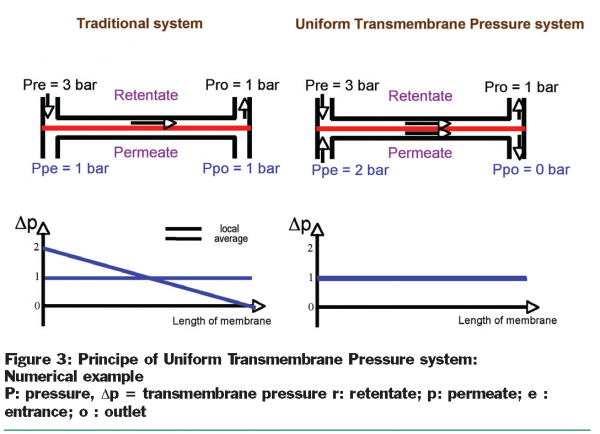

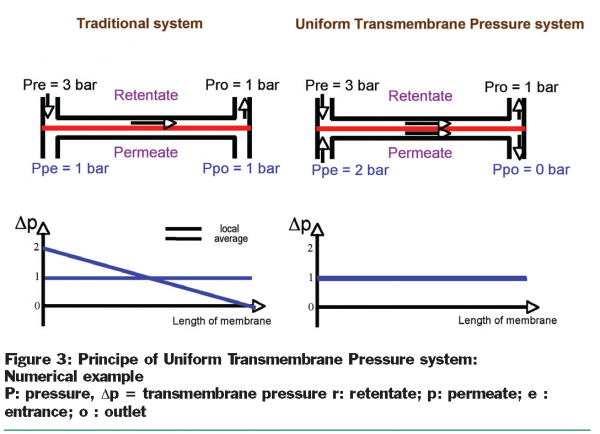

For this application, membranes used are multi-channel ceramic membranes with a pore size of almost 1.4µm. By combining high crossflow velocity (6-9 m s-1) with a low transmembrane pressure (ΔP less than 50kPa), the membranes lead to low matter losses (five per cent in volume at a volume reduction factor, VRF is equal to 20 with a casein retention of less than one per cent) at high fluxes (J is equal to 400–650 L h-1 m-2) for 10 h. In large equipment, a second MF stage can be added to concentrate further the first retentate. (Figure 2)4 In order to get such performances, homogeneous filtration conditions should be maintained throughout the filtering path, either using the uniform transmembrane pressure system (developed by Alfa Laval under the trademark Bactocatch, Figure 35) or novel ceramic membrane with linear hydraulic resistance gradient6.

The skimmed milk MF makes it possible to decrease the microbial load of milk, while maintaining the organoleptic quality of milk due to low heat treatment (37-50°C). Average decimal reduction of bacteria is good, above 3.5, which means that the microfiltered milk, in our countries, contains between 10 to 50 CFU ml-1.

Several hundred of these systems (10–20 m3 h-1) are currently running in Europe and North America for the manufacture of drinking milk. Due to high retention of bacteria and spores, such a process is used, with some adaptations, by the cheese-makers to produce safe raw milk cheeses.

1.2 Selective concentration of casein micelles for cheese-making

For 10 years, MF using a 0.1µm mean pore membrane diameter has enjoyed rapid industrial development due to the high quality and properties of the two produced fractions: a retentate which is milk increasingly enriched in native casein micelle (size is almost 100-150nm, Figure 1) and a clear and sterile microfiltrate. Separation is usually performed at 50-55°C, at a VRF of 2-3 with flux of almost 75 L.h-1.m-2 according to critical stability criterion, which allows the industry to perform long runs with very moderate fouling and high selectivity.7

The permeate, with a composition close to that of a whey, contains whey proteins in their native state, is sterile, free of phage particles and fat, and becomes therefore a useful fluid to prepare whey protein concentrates, WPC. Concentration by ultrafiltration, UF with a cut-off of almost 10kg mol-1, directly produces WPC with a protein ratio of 77 per cent.

The retentate is used for the casein enrichment of cheese milk to improve the cheese-making process: shorter rennet coagulation time, accelerated curd firmness kinetics and increased final curd firmness. In addition, partial removal of whey proteins significantly reduces the detrimental effects of heat treatment on rennet milk coagulability, and is used to develop a new high-heat milk powder, with a cheese-making ability similar to that of raw milk.2

Finally, purified casein micelles, obtained by diafiltration against water, and WPC obtained after UF of milk microfiltrate, are excellent starting fluids for further fractionation of individual caseins or whey proteins.

Separation of small milk fat globules from large ones has recently been proposed using MF.9 It is claimed that the use of small globule fraction yields more unctuous yoghurts, soft and hard cheeses.

Ultrafiltration

2.1 Standardisation and concentration of milk proteins10

For more than 30 years, UF has been used on milk processing plants, for the milk standardisation in total protein for drinking and cheese milks. Standardisation of the protein content of the milk results in a consistent milk composition all year round, independent of seasonal variations, and then results in more constant process and product quality, better use of existing equipment and increased cheese yields. Spiral wound membranes or tubular ceramic membranes with a cut-off of less than 10kg mol-1 are used for this application, at a pressure of 200–400kPa and flux of 30–120 L h-1 m-2.

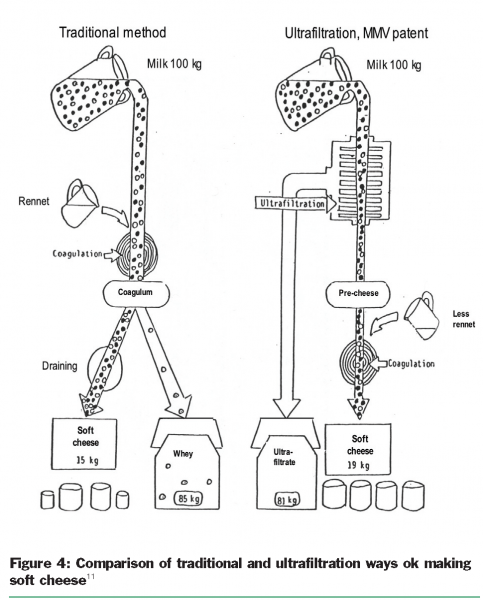

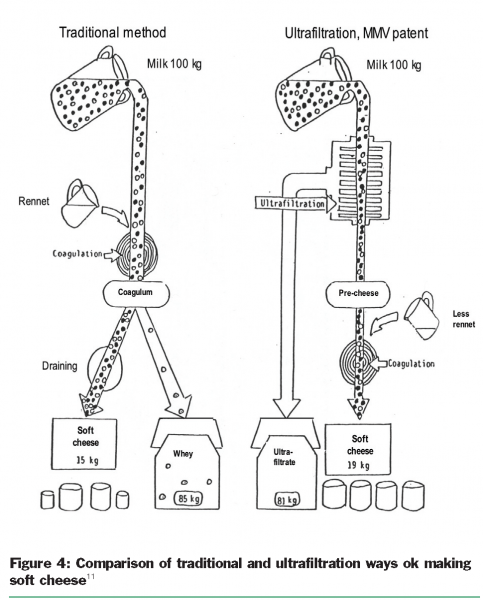

A UF step has also been directly incorporated into cheese-making in what is known as the MMV process after the investigators (Maubois, Mocquot and Vassal) who originally developed this process in 1969.10,11 The general idea behind this process is to remove the excess water and lactose by an initial UF step prior to coagulation, thereby eliminating the need to separate the whey from the curd (Figure 4). All the proteins are therefore concentrated together in the pre-cheese fluid. The appropriate enzymes and micro-organisms (starter) are then added into the protein concentrate to coagulate. In the MMV process, VRF can reach seven in order to prepare a pre-cheese with a protein content similar to the protein content of the final cheese. UF can also be used for the production of pre-cheese with intermediate concentration, the final concentration being reached according to conventional adapted technologies.

The advantages of the MMV process for cheese production are great. The overall cheese yield is about 10-30 per cent higher than in the traditional process since the whey proteins are included in the pre-cheese. Enzyme usage is generally reduced. The MMV process eliminates the need for the large storage tanks traditionally used for heating and cooking the curds, resulting in a saving in both capital investment and energy costs. In addition, it is possible to use the MMV process to convert much of the cheese production in a continuous operation, leading to significant advantages in terms of overall capital costs and operational efficiency.

Since the seventies, several new cheeses have been produced using UF.

2.2 Concentration of whey proteins

By far the most successful application of membrane processes in the dairy industry is the production of a whey protein concentrates by UF, which occurred in the late 1960s. Until then, the interesting nutritional, biological and functional properties of these proteins could not be fully exploited because of the damaging effect of traditional treatments (acid, temperature) used for their separation from whey.

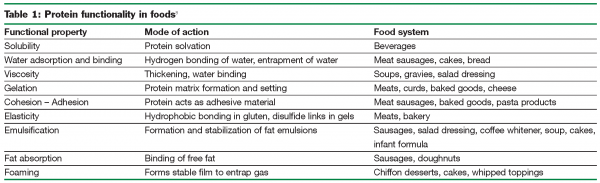

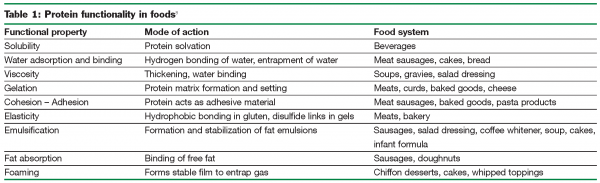

Ultrafiltration membranes, with an appropriate cut-off (10-20kg mol-1) are used to remove both the lactose and ions, yielding a retentate with a high protein concentration. The resulting product can then be further processed by evaporation and spray drying to produce WPC with various interesting functions (Table 1). Even if WPC can be produced by ion exchange (Spherosil and Vistec processes) or gel permeation chromatography, UF operation is, for economical reasons, the privileged way of processing8.

The purity of WPC, ranging from 35 to 85 per cent (expressed in nitrogen N x 6.38 over Dry matter), is directly dependent of applied VRF. For 35 per cent WPC, a VFR of 4.5 to 7.0 is required, although it should reach 13-20 for 50-60 per cent WPC. Combined with a diafiltration, whey UF (VRF 30–35) can lead to WPC purity of 75–85 per cent. Several whey pre-treatments, using membrane operations, have been proposed in order to both increase the purity of the WPC and improve UF performance (especially decreased by residual lipids, calcium phosphate precipitation and protein accumulation)1,8.

In industrial processes, whey UF is performed mainly in multi-stage spiral wound systems with polysulfone membranes. Processes are currently operated at a temperature of almost 50°C, requiring a pre-treatment in order to avoid severe fouling during operation. Flux is about twice as high as flux at 10°C, which is a major incentive for operation at such high temperature. However, due to the rapid decrease in membrane prices, which enable new systems to operate at a temperature of below 15°C, and in respect of microbiological quality of the end product, low temperature process is now favoured.

Nanofiltration, reverse osmosis

Concentration of whey on its production site is the major application of reverse osmosis (RO) owing to its flexibility and energy consumption (9-20 kWh m-3 water removed) compared to vacuum evaporation (almost equal to 100 kWh m-3). The maximum concentration that can be obtained by RO is 18-27 per cent dry matter, limited by high osmotic pressure, high retentate viscosity, calcium phosphate precipitation and lactose crystallisation.

Because of the high salt content of whey (8-20 per cent dry matter), which generates numerous processing difficulties and nutritional imbalance (particularly in infant food), it became advantageous to demineralise whey before evaporation. Whey was demineralised in the range 50-95 per cent by electrodialysis and/or ion exchange, but these operations led to a large volume of polluting effluents, high investment and running costs. Nanofiltration became therefore an industrial alternative, making it possible to reach simultaneously the concentration of dry matter (20-22 per cent at VRF 4-5) and demineralisation (25-50 per cent and even 90 per cent with diafiltration). The process is competitive to RO and electrodialysis. Demineralisation is more selective (high reduction of monovalent ions and low reduction of divalent nutrition value ions like calcium); NF selectivity remains satisfactory even at the highest demineralisation rate; losses of lactose and nitrogen are low. In addition, the NF step significantly improves the technological characteristics of the concentrate and gives it higher value (increase in yield of lactose crystallisation, and low hygroscopy of obtained powders).

Example of combined membrane operations

Extraction of milk and whey proteins

During the past two decades, considerable interest has been paid to the development of fractionation of milk and whey proteins. Fractionation of the main whey proteins, first attempted in the mid 1980s, has recently undergone significant improvements. Among the commercially interesting proteins, the two main whey proteins, α-lactalbumin and β-lactoglobulin can be produced in enriched fractions using membrane processes8,12. α-lactalbumin has a great potential market because of its high content in tryptophan and in infant milk formula. The main uses of β-lactoglobulin appear to be in gel and foam-type products and in the manufacture of protein hydrolysates for food ingredients.

Due to the numerous potential applications of proteins, increased attention is being directed towards large scale production of purified milk proteins, as well as bioactive peptides present in milk proteins sequences. The cost of extracting these proteins is high but often justified when recognising the great value-added benefits when incorporated in hygiene products, functional foods and nutraceutical products.

4.2. Treatment of dairy effluents12

The treatment of effluents strongly benefits from the potentialities of filtrations. Several types of effluents are currently treated in the industry: washing waters of rennet casein precipitate (NF); white (flushing) and pre-rinsing waters (UF, NF, RO). The outcome is a highly significant improvement of water quality after treatment and the re-use of milk components (either as recycling back to the production unit or animal feed). Cheese brines are widely recycled after a MF or UF step, which strongly reduces microbiological counts, without altering the chemical composition (nitrogen, ash) contrarily to conventional pasteurisation. Alkaline and acid Cleaning-In-Place solutions, which are periodically drained to waste due to their pollution load, can be regenerated using NF, UF or MF.

In addition, several companies propose the use of membrane aerobic bioreactor for end-of-pipe wastewaters treatment.

Conclusions

Membrane operations provide the dairy industry with reliable safe, clean and sober processes. These operations have sometimes been used to substitute, either totally or partially, other standard dairy processes and therefore improve traditional processes. But more often, they have made it possible for new and original products to be created which were simply not possible before.

Due to the amount of research that has been focused on the characterisation of milk components, analytical methodologies and separation processes, it is likely that the general quality and production efficiency of the various milk protein ingredients will increase in the near future.

References

- Cheryan M. (1998). Ultrafiltration and Microfiltration Handbook, Technomic Publishing Company, Lancaster PN, USA.

- Daufin G., rené f., aimar p. (1998). Les opérations à membrane dans les procédés de l’industrie alimentaire, Ed. Lavoisier, Tec.&Doc, Paris.

- Saboya L.V., Maubois J.L. (2000). Current developments of microfiltration technology in the dairy industry, Lait 80, 541-553.

- Maubois J.L., Schuck P. (2005). Membrane technologies for the fractionation of dairy components. Bulletin Int. Dairy Fed. 400, 2-7.

- Sandblom R.M. (1974). Filtering process. Swedish Patent 7416257.

- Garcera D., Toujas E. (1998). Macroporous support with permeability gradient and it manufacturing process. European Patent 0870534A1 FR 9704359 1-11.

- Gésan-Guiziou G., Boyaval E., Daufin G. (1999). Critical stability conditions in crossflow microfiltration of skimmed milk: transition to irreversible deposition, J. Membrane Sci., 158, 211-222.

- Maubois J.L., Ollivier G. (1997). Extraction of milk proteins, in: Damodaran S., Paraf A. Eds., Food proteins and their applications, Marcel Dekker, Inc. New York, 579-595.

- Goudédranche H., Fauquant J., Maubois J.L. (2000). Fractionation of globular milk fat by membrane microfiltration. Lait, 80, 93-98.

- Mistry V.V., Maubois J.L. (2004). Application of membrane separation technology to cheese production. In P.F. Fox Ed. Cheese Vol.1 – Chapman & Hall, London.

- Maubois J.L. (1981). Perspectives d’utilisation des techniques à membranes dans les industries agro-alimentaires. Académie d’Agriculture de France, Procès-verbal 26 nov. 1980, 1451-1461.

- daufin g., escudier j.L., carrère h., bérot s., fillaudeau l., decloux m. (2001). Recent and emerging applications of membrane processes in the food and dairy industry. TransIChemE, Part C, 79, 89-102.