Packaging design for fresh produce

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 28 February 2008 | Pramod.V. Mahajan, Oliveira, F.A.R., Montanez, J.C., and Iqbal, T., Department of Process and Chemical Engineering, University College, Cork, Ireland | No comments yet

Ready-to-eat, fresh-cut consumer products are one of the few segments within the industry that has shown consistent growth within the last few years. Cutting however, increases senescence rate and the shelf life of the products can be very limited. Modified atmosphere packaging (MAP), combined with a good cold chain can extend the shelf life, but challenges still exist, due to fresh-cut products containing much higher respiration rates due to the cell stress, caused by cutting.

Ready-to-eat, fresh-cut consumer products are one of the few segments within the industry that has shown consistent growth within the last few years. Cutting however, increases senescence rate and the shelf life of the products can be very limited. Modified atmosphere packaging (MAP), combined with a good cold chain can extend the shelf life, but challenges still exist, due to fresh-cut products containing much higher respiration rates due to the cell stress, caused by cutting.

Ready-to-eat, fresh-cut consumer products are one of the few segments within the industry that has shown consistent growth within the last few years. Cutting however, increases senescence rate and the shelf life of the products can be very limited. Modified atmosphere packaging (MAP), combined with a good cold chain can extend the shelf life, but challenges still exist, due to fresh-cut products containing much higher respiration rates due to the cell stress, caused by cutting.

A high respiring product inside a low permeability film means anoxia soon establishes (absence of oxygen) conditions, under which very dangerous pathogens thrive (e.g. lysteria). Towards the end of 1996, we witnessed the largest outbreak ever recorded in the UK. This originated in Wishaw (Lanarkshire), southwest Scotland. Although the source of infection was traced to cold cooked meats, it is an alarm for other food products like fresh cut fruits and vegetables. There was an outbreak of Salmonella Typhimurium in the United States indicating that tomatoes consumed at restaurants are the food responsible for this outbreak (Centres for Disease Control and Prevention, October, 1996).

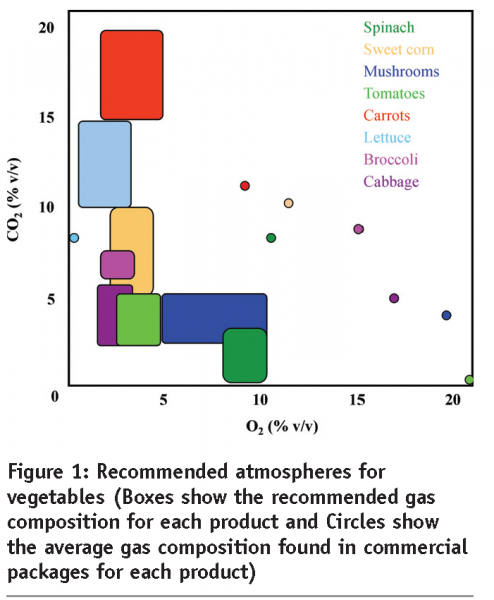

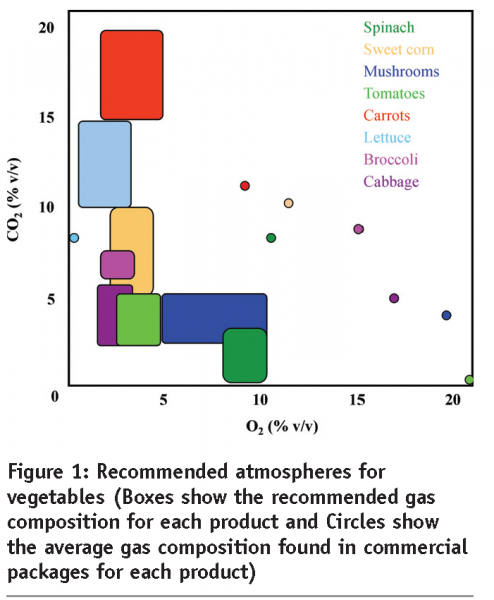

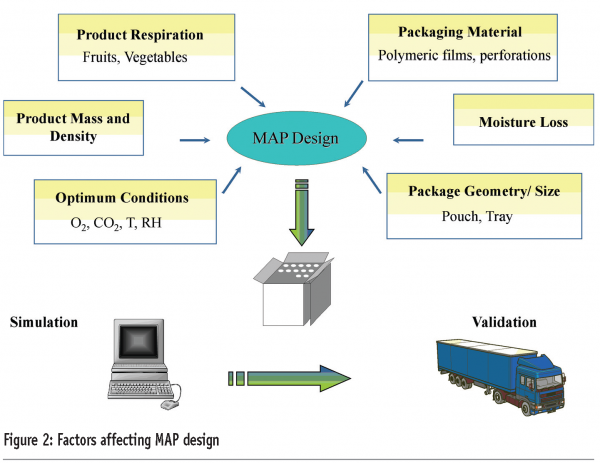

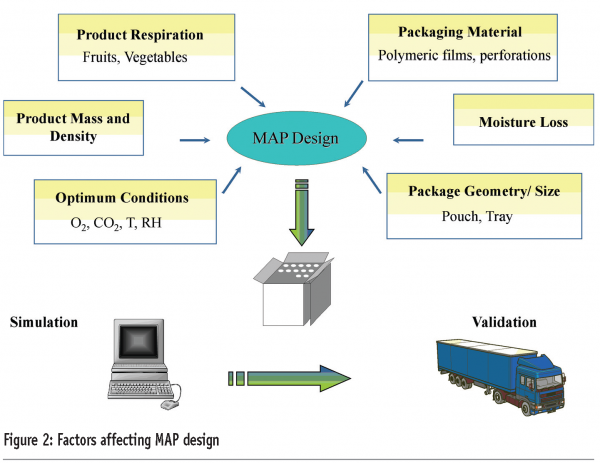

The MAP technique means that the product is packed in a permeable package and preferably stored at refrigerated temperature. The gas composition inside the package is modified to the optimum level for the packaged product, generally low O2 and high CO2, as shown in Figure 1. This passive/natural modification relies on the interplay between the product respiration rate and the gas exchange rate through the package. Proper MAP design is required to achieve the optimal atmosphere by considering the factors shown in Figure 2. A MAP system, if not designed correctly, may be ineffective or even shorten the storage life of a product. The existing commercial packages deviated from the optimum conditions of MAP (Figure 1). This shortens the shelf life with poor quality product and possibility of infection. Simulation is a valuable tool in this context. The shelf-life and packaging group led by Prof. Fernanda Oliveira at University College Cork, Ireland have developed user-friendly software for packaging design for fresh-cut produce. The group is also actively involved in analysis of respiration rate of fresh-cut produce and Perforation-Mediated MAP (PM-MAP) which is an alternative to conventional MAP.

Perforation Mediated-MAP

Polymeric films are widely used in conventional MAP to reach the required gas exchange between the package and its surrounding environment, but their use have certain disadvantages due to their high permeability ratio (permeability of CO2 over permeability of O2) and high gas barrier properties. PM-MAP is an alternative to conventional MAP where gas exchange is regulated by single or multiple tubes inserted into an otherwise impermeable covering. There are some advantages of perforations over polymeric films:

- Permeability ratio close to 1; hence O2/CO2 change is proportional

- Suitable for high CO2 tolerant commodities such as cut-produce

- Flexible permeability is obtained by changing the size and shape of perforation

- Impermeable package material can be used

The work being carried out at University College Cork is to study the different factors affecting the gas exchange rate in PM-MAP. The work was performed on perforation dimensions (diameter and length), temperature and air velocity, perforation locations and free volume of the package and mathematical models have been developed to predict the permeability values of O2 and CO2, through PM-MAP. Results showed that air velocity and tube diameter have a significantly positive effect on the permeability values, whereas tube length has a negative effect. The angle of insertion of perforation tubes located in the package top does not significantly affect the permeability values but insertion of tubes in the package side should be avoided as the mass transfer rates are much higher and would render the package as unfeasible. The tests carried out for scale-up showed that permeability values reported for small packages can be used to design larger packages.

Respiration rate

Respiration is the oxidative breakdown of the complex substrates normally present in the cells, such as carbohydrates, lipids and organic acids, into CO2 and water, with the simultaneous production of energy and other molecules. Measurement and modelling of the respiration rate of fresh produce is the most crucial part for engineering design of MAP systems. Our research showed that low temperature has a significant effect on reduction of respiration rate, with synergistic effect of O2 and CO2. These effects have been in general, very well described, by using the Arrhenius equation, coupled to a Michaelis-Menten model with uncompetitive inhibition. Most recently, Prof. Oliveira and her research team found that the respiration rate increased over storage time and then levelling off. This kind of respiration pattern may have a major impact in the gas composition, achieved in MAP and should be considered, particularly for fresh-cut produce. The effect of time may have a drastic effect if the product is likely to undergo temperature abuse during storage and distribution.

PACK-in-MAP software

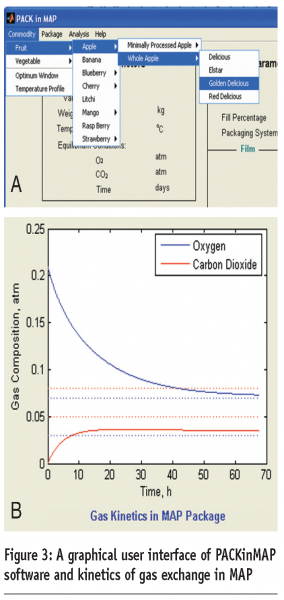

The user-friendly software, PACK-in-MAP, was developed using the Matlab 6.0 programme. It incorporates the database for respiration rate, optimum temperature, and optimum range of O2 and CO2 concentrations, for different fruits and vegetables and permeability of different packaging materials, including PM-MAP. This database is helpful in designing MAP for 38 fresh and fresh-cut products, using 27 polymeric films and micro-perforated packages. Some of the database is made flexible so that users can change as per their requirements.

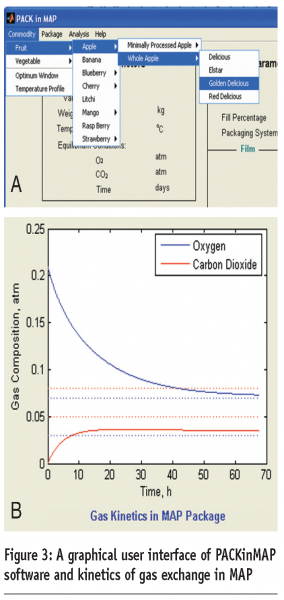

In the Pack-in-MAP software, the user defines the type of product, storage conditions, amount of product to be packed, and size and geometry of the package. The software selects the optimum gas composition (O2 and CO2) and calculates the respiration rate for that product. The software then selects the best possible films and calculates the area of each film, required to achieve the desired gas exchange. Alternatively, the user may specify the area available for gas exchange and the software calculates the amount of product that can be suitably packed. It avoids time-consuming trial and error experiments to determine the best packaging system for the given product. Finally, the software simulates the O2 and CO2 changes over storage time (Figure 3) for the given time-temperature profile, for the particular product.

Acknowledgement

The authors acknowledge financial support from the Irish Government, under the National Development Plan 2000 – 2006.

For further information about the packaging of fruits and vegetables, please call on Tel: +353-214902389 or email [email protected]

Issue

Related topics

Packaging & Labelling, Quality analysis & quality control (QA/QC)