Light waves and food products in display cabinets

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 20 February 2009 | Hanne Larsen & Annette Veberg Dahl, Research Scientists, Nofima Mat AS | No comments yet

The consumers want to see the product they are purchasing. The shops use special lighting in order to sell more, at the same time as prolonging the opening hours. The price the consumer pays for the combination of increased light exposure and the desire to see food products is that the food can be deteriorated by the light. Dairy products develop off-odour and taste faults (‘sunlight taste’), meat products become grey, oily and fatty products turn rancid and vitamins degrade. However, the question is which light waves are most damaging for the food in the display cabinets?

The consumers want to see the product they are purchasing. The shops use special lighting in order to sell more, at the same time as prolonging the opening hours. The price the consumer pays for the combination of increased light exposure and the desire to see food products is that the food can be deteriorated by the light. Dairy products develop off-odour and taste faults (‘sunlight taste’), meat products become grey, oily and fatty products turn rancid and vitamins degrade. However, the question is which light waves are most damaging for the food in the display cabinets?

The consumers want to see the product they are purchasing. The shops use special lighting in order to sell more, at the same time as prolonging the opening hours. The price the consumer pays for the combination of increased light exposure and the desire to see food products is that the food can be deteriorated by the light. Dairy products develop off-odour and taste faults (‘sunlight taste’), meat products become grey, oily and fatty products turn rancid and vitamins degrade. However, the question is which light waves are most damaging for the food in the display cabinets?

Ultraviolet (UV) light is the short wavelength light ranging from 100 to 380 nanometres (UVC: 100-280 nanometres, UVB: 280-315 nanometres and UVA: 315-380 nanometres), while the visual light with longer wavelengths are in the range from 380 to 780 nanometres. UV light possesses more energy than visual light and its harmful effect on the human skin (UVB in particular) is emphasised when people are exposed to sunlight for long periods. It is a widespread perception that UV light is also the most harmful light in relation to lighting for food products and this is correct for some food products. However, to which degree are the food products exposed to UV light in the grocery stores?

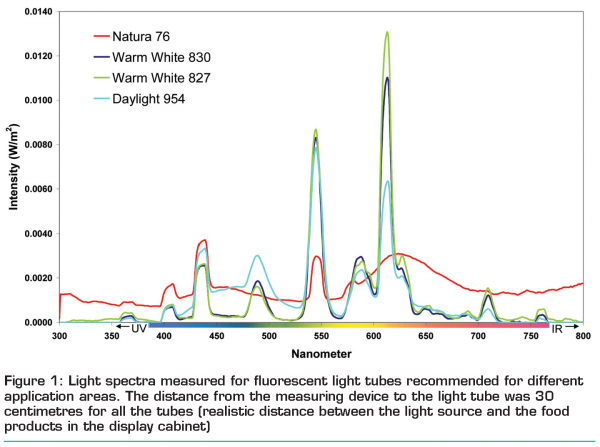

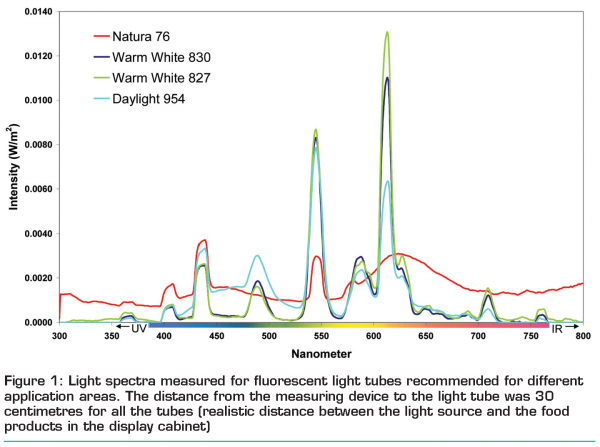

Light spectra measured for different fluorescent light tubes

Four different fluorescent light tubes from Osram (Oslo, Norway) were mounted in a specially designed cabinet with separated ‘rooms’ for each light tube. Light intensity from each light tube was measured by a spectroradiometer (Apogee Spectroradiometer, Apogee Instruments Inc., Logan UT, USA), which was calibrated in the 300-800 nanometre region. The distance between the light tube and the spectroradiometer measuring device was 30 centimetres. The results are shown in Figure 1. The fluorescent tubes used in the experiment were recommended for the following areas of application:

- Natura 76 (L 58W/76 Natura) used in display counters for meat products: this light has a high portion of wavelengths in the red area to emphasise the red colour of fresh and processed meat products

- Warm white 830 (L 58W/830 Lumilux – Warm White) which is often recommended for use in display counters for dairy products. This light has a great portion of light waves in the yellow and orange area

- Warm white 827 (L 58W/827 Lumilux – Interna) which gives an even ‘warmer’ (yellow) lighting than 830. This light is recommended for use in the ceiling in shops and at home

- Daylight 954 (L 58W/954 Lumilux de luxe – Daylight), recommended for use in medical offices, for example, where a good colour rendering is necessary. This light has a great portion of wavelengths in the blue region

UV light in the area below 300 nanometres was not measured. According to information from Osram, their light tubes do not emit light in the UVC-area (100-280 nanometres). A commercial white light (840 Cool White) has ca 0.2 per cent of the total light energy in the UVB region (280-315 nanometres) and two per cent in the UVA region (315-380 nanometres). This is also demonstrated in Figure 1, where some UVA light was measured in the range from 360-370 nanometres, with the highest intensity in this area for the light tube recommended for meat products. Figure 1 shows that, in general, none of the light tubes emit much UV light. However, the light tube recommended for meat products have slightly higher values compared to the others in the whole UV light region. Natura 76 for meat products also had a smoother intensity curve compared to the other tubes, with less high intensity peaks in specific areas. Warm white 830 and 827 had relatively similar spectra, with high intensity peaks in the yellow wavelength region (particularly at approximately 550 and 610 nanometres). The daylight tube had in general higher intensity in the blue-green region compared to warm white 830 and 827. Figure 1 shows that some UV light is emitted from all the tubes used for lighting in the grocery stores. The next question is; how much of this UV light passes through to the food products?

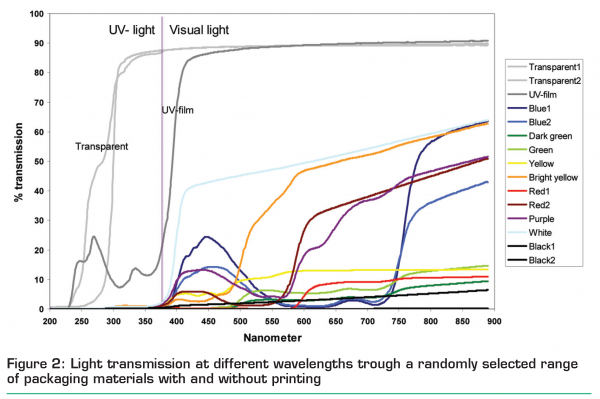

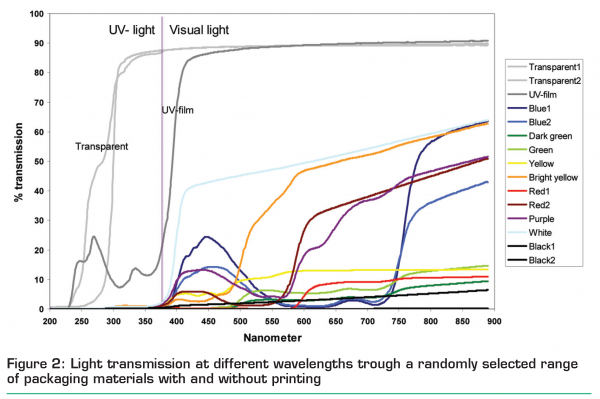

Light barrier in packaging materials

One consequence of the focus on UV light is that many packaging materials have been developed with UV barriers. Different types of UV absorbing substances can be added to the plastic goods in order to give the finished packaging UV barriers. In order to study which wavelengths pass through different packaging materials, several food products were randomly selected from a grocery shop. The food products were packaged in polymer materials without printing (transparent) and with printing in different colours. Pieces with and without printings were cut out from the materials and placed into a Lambda 800 UV/VIS spectrometer (Perkin Elmer Instruments, Norwalk, USA). The light transmission through a commercial film with UV-barrier was measured as well. The spectrometer measures the percentage of light transmission through the materials for light waves in the range from 200 to 900 nanometres. The results from the measurements are shown in Figure 2.

Figure 2 shows that the two transparent materials have slightly different light transmission curves, but both of them transmit all wavelengths above approximately 275 nanometres, including the UV light. The film with a UV-barrier excluded 80-90 per cent of the UV light, but transmitted all the visual light above 400 nanometres. Materials with printing do not transmit UV light, while in different degrees they transmit the visual wavelengths (> 380 nanometres). The UV light is blocked in white and printed materials due to titan dioxide added to the material. Titan dioxide is added to white materials to give the white colour. For printed materials, the titan dioxide is applied as a ground colour before the other colours are applied on top. In general, materials with added titan dioxide do block all light waves up to approximately 400 nanometres.

From Figure 2 we can also observe that blue printing transmit a relatively high portion of blue light waves (400 to 500 nanometres) for example, but at the same time, it protects against transmission of the other visual light wavelengths. The red printing has low transmission in the blue region, but transmits relatively more of the red light. Transparent and black materials of different origins had slightly different light transmission. Figure 2 shows that just the transparent materials transmit the UV light emitted from fluorescent light commercially used in grocery stores. The next question will be how the different light waves, and in particular the UV light, influence the food quality.

Light sensitive components in the food absorb light with different light waves

Photosensitisers are light absorbing components present in different foods. The photosensitisers can be of both natural and synthetic origin. To evaluate the potential detrimental effect of a light source on a food product, the photosensitisers that are present in the food product, and which wavelengths these components absorb, must be studied. The absorbed light energy, if oxygen is available, will be transferred from the photosensitisers to the oxygen, forming singlet oxygen. Singlet oxygen is very reactive and will ‘attack’ double bonds in unsaturated lipids causing decomposition into smaller compounds with rancid odour and taste, for example. Many food products contain many different photosensitisers and it is often difficult to predict how these sensitisers will interact with antioxidants and other ingredients in the food product.

A common, naturally occurring photosensitiser, riboflavin (vitamin B2, which can be found in dairy products, for example), absorbs light in the UV region, but it also absorbs light in the visual light region, with an absorption peak at 450 nanometres. Other photosensitisers, such as chlorophyll (pigment in fruit and vegetables) and heme compounds (pigment in meat products) absorb light waves mainly in the visual light region, but also some light waves in the UV region. Since most of the photosensitisers absorb light in the visual light region, a UV barrier in the packaging material will not protect the food product against the chemical reactions caused by these photosensitisers. Figure 2 shows that the different printing colours in varying degree protect against the light waves in the visual light region.

Visual light just as detrimental to foods as UV light

The argumentation shows that the visible light, which is emitted from normal fluorescent tubing in the grocery shops, is just as harmful to the food products as the small quantity of UV light that is emitted from the fluorescent tubes. However, if the food products are exposed to sunlight, a high portion of UV light in addition to the visual light will rapidly damage many food products. The use of a UV barrier in the packaging material will have some protective effect in these cases.

How to reduce deterioration of foods due to photooxidation

One possibility is to minimise the light exposure by selecting light sources with a minimum of damaging light waves or by increasing the distance between the food and the light source. The amount of light energy the food product is exposed to is reduced by the quadrate of the distance; i.e. if the light intensity is 1 W/m2 at 0.5 metres, the light intensity will be 0.25 W/m2 at a distance of one metre.

Another possibility is to use packaging solutions that protect the products against photooxidation. This can be performed by reducing the light transmission through the packaging materials and/or by reducing the oxygen available for the photosensitised reactions. A light barrier can be incorporated in the packaging material using different methods, e.g. by adding pigments to the polymers prior to package manufacturing, metallisation of one layer in the laminated films, use of fibre based combination materials where the fibre material gives light protection, or by applying the light protection on the outside of the package by printing or the use of labels. Cooked and sliced meat products, such as cooked ham, are subject to pigment fading, turning from pink to grey when they are exposed to the combination of light and oxygen. In many European countries, this problem is solved by using a lightproof top web (laminate with a metallised layer incorporated), as shown in the picture. The bottom web of the packages is transparent and the consumer can inspect the product just by turning the package.

If a transparent package is preferred, it is crucial to minimise the level of oxygen in the packages and the choice of packaging method and material are of great importance. Packaging materials with a high oxygen barrier should be employed and the residual oxygen level in the packages should be as low as possible for many products, depending on how sensitive the products are to photooxidation. The amount of oxygen in the package available for oxidative reactions is dependent on both the oxygen concentration and the headspace volume in the package. Transparent packages are used for cooked and sliced meat products, for example, in Scandinavian countries and the oxygen level has to be low in these packages to avoid colour fading. In a study performed at Nofima Mat, the oxygen concentration threshold level was found to be as low as 0.15 per cent in the headspace for a cooked ham product with a gas volume to product volume ratio of 2.6. The ham in transparent packages with oxygen levels below this threshold level did not turn grey during 48 hours of light exposure under normal grocery shop conditions.

Experience at Nofima Mat

Nofima Mat is working on identifying important light-sensitive substances in different food products and determining the quantitative and qualitative parameters of the way they work. This knowledge will be exploited in order to develop and document the necessary requirements for the packaging’s light and oxygen barriers and to prevent the quality deterioration in primarily meat and milk-based food products.