Effect of hydrodynamic postprocessing on properties of protein rich and low fat yoghurts

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 13 December 2016 | Cyril Chaudemanche (General Mills) | 1 comment

Over the course of the last decade we have seen a global evolution in consumers’ expectations. They are transitioning progressively towards healthier lifestyles and their purchasing behaviour is now mainly driven by authentic, simple and naturally healthy products.

It is thus unsurprising to see that the functional and naturally healthy dairy products industry is an expanding market worth US$130 billion1 among which the ‘reduced fat dairy’ category represents the second largest business behind the ‘functional and fortified’ category. According to the data published in the Food and Health survey in 2015, 53% of consumers in Europe pay attention to fat content, and in the US 61% categorise fat as not really healthy. This survey helps to explain why dairy fat reduction drives innovation in the yoghurt category, as ‘low/no fat’ is in the top three claims of newly launched dairy products in Europe2 . A better management of food by restriction of energy intake from total fat consumption can help reduce weight and decreasing obesity – the two primary risk factors for chronic diseases3 . In this context, General Mills, whose purpose is to “serve the world by making food people love”, is on the front line delivering healthy and delicious dairy products to consumers, and hence playing an active role in the limitation of food intake and weight management.

Creaminess and fat replacers

Despite this increased awareness on obesity levels and diseases related to fat, consumer sensory studies show that fresh dairy products with higher fat content are always preferred over lower fat variants4,5. When consumers are asked more specifically to select the words that best describe high fat fresh dairy products, the main attributes defined are ‘creamy and smooth texture and creamy taste’6,7. Understanding the notion of ‘creaminess’ is therefore a key consideration in order to deliver no- or low-fat fresh dairy products, without compromising the organoleptic perception. Recently, many research teams have tried to describe the complex and multidimensional notion of ‘creaminess’8-12 and despite the difficulties in defining this descriptor, it seems to be associated with the following combination of sensorial attributes: shiny appearance, fatty taste, smoothness, thickness, mouth coating, slipperiness and melting rate. Hence, the development of no or reduced fat yoghurt would require replicating the scores for the sensorial descriptors associated with a full fat product.

Many attempts have been made to more precisely elucidate the role of dairy fat in a protein environment by mimicking the eating process through a multi-scale approach combining rheology, tribology, particle size measurements and confocal laser scanning microscopy13-15. Apart from affording more understanding on how fat globules interact with the protein matrix, these studies enabled further specification on what should be the structural and textural properties that should be matched by a fat replacer. The possibilities to vary these properties are numerous. In terms of fat substitutes, commercial ingredients such as hydro – colloids16, fibres17-20, whey proteins21-23, starches24,25 or a combination of them26,27 are widely used in the fresh dairy sector. In general, these ingredients are an efficient means of increasing the thickness and/or the melting rate of no/low fat yoghurts, but can only develop limited mouthfeel and often impact negative textural effects such as ‘sliminess’ or ‘stringiness’. To date, even if some of these ingredients have produced closed results versus the full fat variants from a rheological point of view, there is still a gap to bridge to obtain, for example, the same tribological or lubrication properties.

In the following sections we will discuss an alternative approach to delivering creamy mouthfeel in no/low fat dairy products via the use of post-processing operations. The product category we have selected for this study is the Greek-Style Yoghurt due to its greater nutritional properties than regular yoghurt (higher protein and mineral concentrations). Two different post-processing operations have been selected for this study, namely: a Rotor/Stator (RS) system and a Shock Wave Reactor (SWR). After presenting a short description of each unit operation, their effects on textural (particle size, rheology, tribology), structural (based on CLSM analysis) and sensorial properties (tactile attributes mainly) are presented, with the objective of identifying processing parameters for fat-free yoghurts leading to a smooth and creamy texture, similar to a full-fat control yoghurt.

Rotor/Stator system and Shock Wave Reactor

In the dairy industry there are many postprocessing technologies that are being studied at pilot plant scale28, but only few can be used at an industrial scale after fermentation. This is the case for Rotor/Stator systems and Shock Wave Reactors. Rotor/Stator assembly consists of a rotor of two or more concentric rows of slots and a stator with vertical slots, whose dimensions can differ from those of the rotor. The rotor is housed concentrically inside the stator. As the rotor rotates, it generates a vacuum to draw the liquid in and out of the assembly, thereby resulting in circulation. One of the two major forces that can impact the yoghurt is the mechanical impingement against the wall, due to high fluid acceleration and the shear force taking place within each slot and the gap between the rotor and the stator. Another postprocessing operation that can be used on an industrial scale is the Shock Wave Reactor. This is a combination of an outer stationary cylinder and an inner rotating cylinder with annular space, which can house the fluids. Cavitation is generated when the inner rotor, which contains multiple holes on its surface, rotates at high speed while in contact with the fluid within the annular space. The dimensions of the holes in the rotor, the inlet pressure, and the flow rate of the fluid into the annular space can be controlled and gives certain flexibility to the system. Recently, some researchers29 have tested this device on Greek-Style Yoghurts after fermentation and they found that lower consistency, hardness and adhesiveness were obtained with increasing cavitational intensities.

Post-processing and effect on textural, structural and sensorial properties

The effect of post-processing on six Greek-Style Yoghurts (GSY) was studied, including a full-fat control. Table 1 outlines the yoghurt systems that were used within the present study.

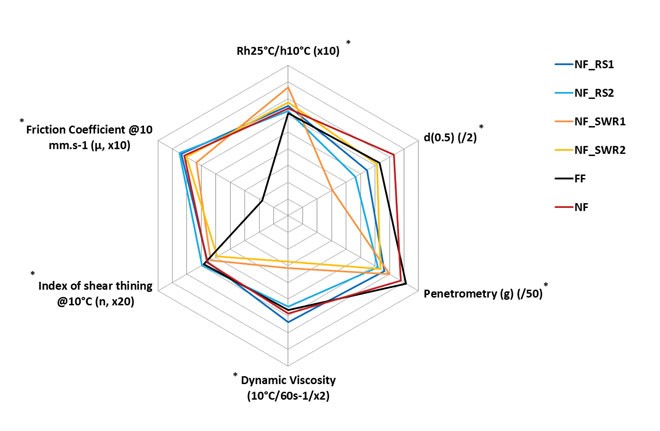

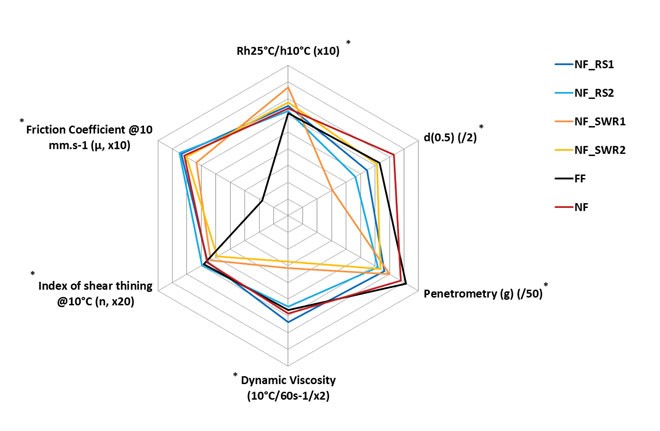

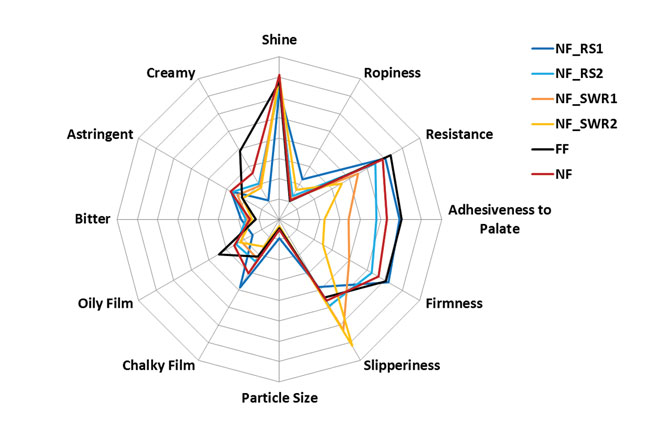

Figure 1: Impact of post-processing conditions on the textural properties of GSY and comparison with a full fat variant. Each parameter has been normalized for a purpose a comparison. (* indicates a significant difference at 5%)

For each GSY, the particle size distribution of microgel particles (d(0.5)); the rheological behaviour (including the dynamic viscosity, the shear thinning index and the ratio of viscosities at 25°C and 10°C); the penetrometry and the tribological behaviour (friction coefficient) were measured according to protocols that can be found in the literature15. The comparison of the textural properties presented in Figure 1 shows that post-processing significantly decreases the firmness of the GSY and the size of the microgels. Surprisingly, when the intensity of cavitation using SWR increases, we notice larger particle size that might be explained by a re-aggregation of proteins after the pressure relief at the outlet of the unit operation. It is also interesting to observe that cavitation induced by SWR drastically lowers the dynamic viscosity, which is not the case for the RS system. RS systems are known to stretch the proteins, which in turn might contribute to higher viscosities. It also appears that the ratio of viscosities (Rh25°C/h10°C) and the shear-thinning index are relatively unchanged by post-processing conditions except for NF_SWR1 and NF_SWR2, which show the highest ratio and the lowest index respectively. This result indicates that NF_SWR1 should be more sensitive to temperature and might present a higher melting rate than the other products, whereas NF_SWR2 should be slightly less sensitive to shearing. These results are in accordance with the literature, where it has been found that hydrodynamic cavitation was at the origin of an increased meltaway in GSY30. Finally, except for NF_SWR1, none of the other post-processing conditions affect the friction coefficient; this parameter being known to be driven by the fat content31.

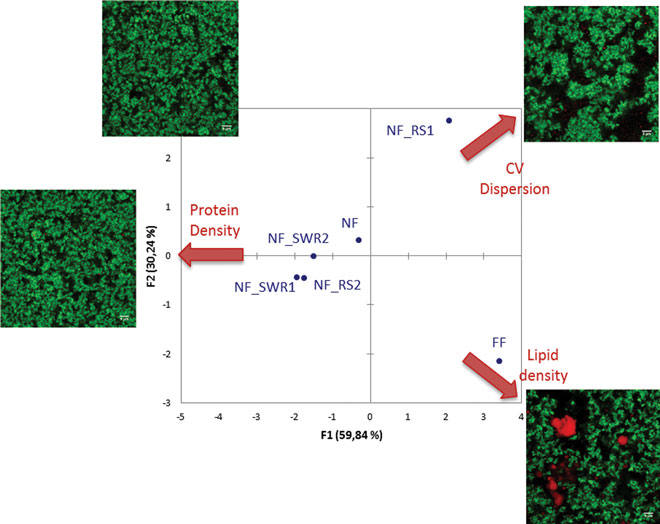

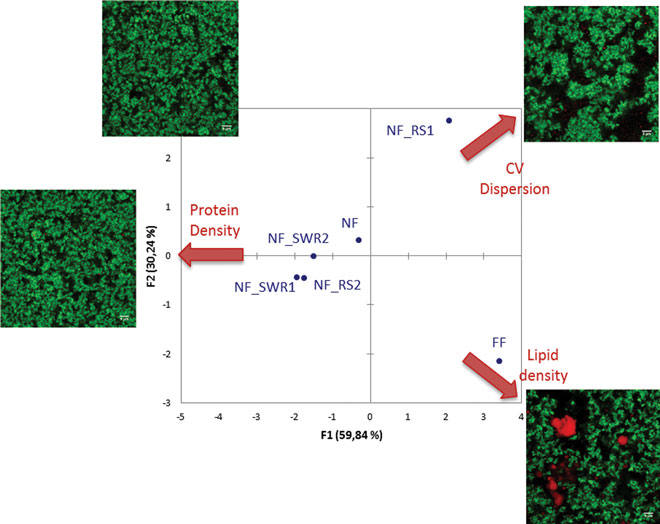

To more specifically clarify the impact of each post-processing condition, a detailed structural analysis has been performed at room temperature, using a confocal light scanning microscope (Zeiss LSM 710 Dynascope) with an excitation source at 561nm and a spectral resolution of 9.7nm. Two fluorochromes were used to dye both the proteins (with Fast Green 166µM in ultra pure water) and the fat globules (with Nile Red 10µM in DMSO 100%) and 10 pictures were successively recorded for each GSY, representing a stack of 5.4µm. The deconvolution of the data was achieved via the algorithm ‘Linear Unmixing’ from the software Zen2010. From these stacks, five parameters were quantified: Lipid density, protein density, Lipid/Protein ratio, the association coefficient, and the dispersion of the protein network. Figure 2 presents a comparison of the different structures obtained via statistical analysis using the software XLSTAT (Addinsoft, France, vs. 2012.2.05). Structural differences among the Greek-Style Yoghurt systems were analysed by Principal Component Analysis (PCA, P < 0.05) and displayed using a PCA biplot.

Figure 2: PCA biplot (P < 0.05) of the GSY presented in Table 1 associated with CLSM pictures of the most representative structures

Removing the dairy fat in GSY induces an increase in the protein density that can be observed with the sample NF. The use of SWR at medium or high intensities contributes toward improving the homogeneity of the protein network and making it denser. However, it is interesting to see that NF_RS1 gives a higher dispersion of proteins, which is not the case for NF_RS2. The difference comes from better protein dispersion in the network with a high intensity treatment. Thus, adjusting the frequency, the geometry and the number of R/S seem to be a lever to modulate the structure and obtain a more heterogeneous protein network compared to SWR.

Using the same products a quantitative descriptive analysis was performed to define from a sensorial standpoint each GSY and to evaluate the impact of post-processing on the organoleptic perception. Table 2 gives the definition of each attribute assessed by the panellists. Products were evaluated by 12 trained panellists under day light and at room temperature. Products were presented blind (into plastic cups) in a sequential monadic way, following a balanced randomised presentation (Latin square) to avoid order effects. Sensorial descriptors associated with appearance, texture in spoon, texture in mouth and basic tastes and aromas were scored.

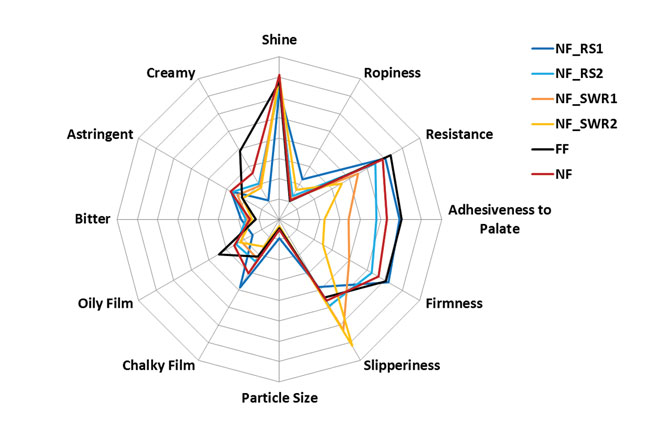

Sensory results given in Figure 3 indicate that FF (control product) presents a higher resistance in spoon; oily film perception; and creamy note intensity in the mouth than the rest of the GSY. On the contrary, NF product is characterised mainly by an intense chalkiness and astringency; a low oily film perception; and an intermediate resistance in spoon, adhesiveness and firmness. It is interesting to observe that all the products with post-processing treatments differ from the FF and NF by low creamy note intensity. However, differences can be noted among them. For example, a medium intensity applied to NF (Product RS1) significantly increases the ropiness and chalkiness but at the same time gives similar adhesiveness and firmness than FF products. A higher smoothing intensity with the RS is also at the origin of an enhanced perception of slipperiness and a lower adhesiveness and firmness, which might be explained by a more homogeneous and shearsensitive network of proteins (Figure 1 and Figure 2). Finally, the sensory perception of SWR1 and 2 products is mainly driven by a low resistance, firmness and adhesiveness to the palate; significantly lower than the rest of the GSY. This result has to be associated with a very homogenous network of proteins and a low dynamic viscosity as shown previously. It is also worth mentioning that the positive effect of the SWR system is a significant improvement in slipperiness compared to the control product.

Figure 3: Comparison of sensory attributes for each GSY performed by texture expert panel, including appearance, texture in spoon/in mouth and basic tastes and aroma. (Only attributes with significant differences at 5% are presented)

Conclusion and perspectives

In conclusion, our results clearly show that hydrodynamic post processing treatments mainly impact tactile attributes and related textural parameters without giving the same sensory profile as full fat Greek-Style Yoghurts. These operations, and especially Shock Wave Reactors, are nevertheless able to modulate the protein structure, which in turn can contribute to beneficial effects such as the reduction of the adhesiveness or the improvement of the slipperiness. As could be expected, none of the post-processing systems tested are able to enhance the creamy flavour intensity, which is clearly a driver of the ‘creamy taste’ required by consumers. This implies that levers to develop creamy taste from a volatile standpoint, such as aromas, need to be identified in order to compensate for the absence of fat in fat-free Greek Style Yoghurts. As presented previously, consumers find that fat is not really healthy. To overcome this negative image, a perspective could be to deliver full-fat fresh dairy products using only healthy fat fractions. The objective would not be to deliver ‘reduced fat’ dairy products anymore but ‘selected fat’ dairy products.

About the Author

Cyril Chaudemanche has been working at the General Mills Vienne Technical Center for the One Global Dairy platform since October 2010. He is a Senior Technology Engineer and holds a position as Expert in Food Texture and Structure. Cyril has an academic background with a PhD in Material Science and Engineering from Mines ParisTech, France and extensive know how within textural characterisation of biopolymers and complex fluids from his previous experiences in the petroleum and the bioplastic sectors. He leads various transversal and global research programmes on topics as wide as ‘factory of the future’, ‘emerging technologies for unique product differentiation’ and ‘fat functionalisation’, with the ultimate objective of delivering dairy products with value added benefits that will fulfil consumers’ expectations.

References

- Euromonitor International (2013). Global Health & Wellness Dairy market: 2008 – 2018

- Mintel GNPD website. Market analysis from Jan 2014 to July 2015

- World Health Organization (2003). Diet, nutrition and the prevention of chronic diseases. Report of a joint FAO⁄WHO expert consultation

- Rapp E, Öström Å, Osika W, Englund A, Annett J, Gustafsson IB. (2009). Preference for full-fat over low-fat foods among individuals suffering from coronary heart disease and healthy controls. Physiology & behavior. 2009 Oct 19; 98(4):489-97

- Drewnowski A. (1991). Why do we like fat? Journal of the American Dietetic Association. 1997 Jul 31; 97(7):S58-62

- Hamilton J., Knox B., Hill D. and Parr H. (2000). Reduced fat products-Consumer perceptions and preferences. British Food Journal. 2000 Aug 1; 102(7):494-506

- General Mills Internal Consumer test using Check All That Apply analysis, March 2014

- Kokini J.L. (1985). Fluid and semi-solid food texture and texture taste interactions. Food Technology, 39, 86-94

- Szczesniak A.S. (2002). Texture is a sensory property. Food Quality and Preference, 13, 215-225

- de Wijk R.A., Terpstra M.E.J., Janssen A.M. & Prinz J.F. (2006). Perceived creaminess of semi-solid foods. Trends in Food & Science Technology, 17, 412-422

- Pascua Y., Koç H. & Foegeding E.A. (2013). Food structure: Roles of mechanical properties and oral processing in determining sensory texture of soft materials. Current Opinion in Colloid & Interface Science, 18, 324–333

- Cayot P., Schenker F., Houzé G., Sulmont-Rossé C. & Colas B. (2008). Creaminess in relation to consistency and particle size in stirred fat-free yogurt. International Dairy Journal, 18, 303-311

- Krzeminski A., Tomaschunas M., Köhn E., Busch-Stockfisch M., Weiss J. & Hinrichs J. (2013). Relating creamy perception of whey protein enriched yogurt systems to instrumental data by means of multivariate data analysis. Journal of Food Science, 78(2), 314–319

- Liu K., Stieger M., Van Der Linden E. & Van De Velde F. (2015). Fat droplet characteristics affect rheological, tribological and sensory properties of food gels. Food Hydrocolloids 44, 244-259

- Huc D., Michon C., Bedoussac C. & Bosc V. (2016). Design of a multi-scale texture study of yoghurts using rheology, and tribology mimicking the eating process and microstructure characterisation. International Dairy Journal, 61, 126-134

- Brennan C.S. and Tudorica C.M. (2008). Carbohydrate-based fat replacers in the modification of the rheological, textural and sensory quality of yogurt: comparative study of the utilization of barley beta-glucan, guar gum and inulin. International Journal of Food Science and Technology, 43, 824-833

- Solowiej B., Glibowski P., Muszynski S., Wydrych J., Gawron A. and Jelinski T. (2015). The effect of fat replacement by inulin on the physico-chemical properties and microstructure of acid casein processed cheese analogues with added whey protein polymers. Food Hydrocolloids, 44, 1-11

- Balthazar C.F., Varon Gaze L., Da Silva H.L.A., Pereira C.S., Maia Franco R. et al. (2015). Sensory evaluation of ovine milk yoghurt with inulin addition. International Journal of Dairy Technology, 67

- Salvatore E., Pes M., Mazzarello V. and Pirisi A. (2014). Replacement of fat with long-chain inulin in a fresh cheese made from caprine milk. International Dairy Journal, 34, 1-5

- Crispin-Isidro G. Lobato-Calleros C., Espinosa-Andrews H., Alvarez-Ramirez J. and Vernon Carter E.J. (2014). Effect of inulin and agave fructans addition on the rheological, microstructural and sensory properties of reduced-fat stirred yogurt. LWT-Food Science and Technology, 62, 438-444

- Celigueta Torres I., Janhoj T., Ostergaard Mikkelsen B. and Ipsen R. (2011). Effect of microparticulated whey protein with varying content of denatured protein on the rheological and sensory characteristics of low-fat yoghurt. International Dairy Journal, 21, 645-655

- Jorgensen C.E., Abrahamsen R.K., Rukke E.-O., Johansen A.-G., Schüller R.B. and Skeie S.B. (2015). Improving the structure and rheology of high protein, low fat yogurt with undenatured whey proteins. International Dairy Journal, 47, 6-18

- Chung C., Degner B. and McClements D.J. (2014). Development of reduced-calorie foods: microparticulated whey proteins as fat mimetics in semi-solid food emulsions. Food Research International, 56, 136-145

- Sandoval-Castilla O., Lobato-Calleros C., Aguirre-Mandujano E. and Vernon-Carter E.J. (2004). Microstructure and texture of yogurt as influenced by fat replacers. International Dairy Journal, 14, 151-159

- Morell P., Hernando I., Llorca E. and Fiszman S. (2015). Yogurts with an increased protein content and physically modified starch: rheological, structural, oral digestion and sensory properties related to enhanced satiating capacity. Food research International, 70, 64-73

- Krzeminski A., Prell K.A., Busch-Stockfisch M., Weiss J. and Hinrichs J. (2014). Whey protein-pectin complexes as new texturizing elements in fat-reduced yogurt systems. International Dairy Journal, 36, 118-127

- Chung C., Degner B. and McClements D.J. (2014). Reduced calorie emulsion-based foods: protein microparticles and dietary fiber as fat replacers. Food Research International, 64, 664-676

- Sfakianakis P. and Tzia C. (2014). Conventional and Innovative Processing of Milk for Yogurt Manufacture; Development of Texture and Flavor: A Review, Foods, 3, 176-193

- Meletharayil G.H., Metzger L.E., Patel H.A. (2016). Influence of hydrodynamic cavitation on the rheological properties and microstructure of formulated Greek-style yogurts. Journal of Dairy Science, 99, 8537-8548

- Mimouni A. and Romero J. (2016). Cavitated fermented dairy product. Patent W0 2016/063101 A1

- Selway N. & Stokes J.R. (2013). Insights into the dynamics of oral lubrication and mouthfeel using soft tribology: differentiating semi-fluid foods with similar rheology. Food Research International, 54, 423-431.

Wonderful article with a new perspective.