New era for hygienic food manufacturing

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 31 January 2005 | Hilde Cnossen, M.Sc., Jacques Kastelein, Drs. Jan Willem van der Kamp, TNO Nutrition and Food Research, Zeist, Netherlands | No comments yet

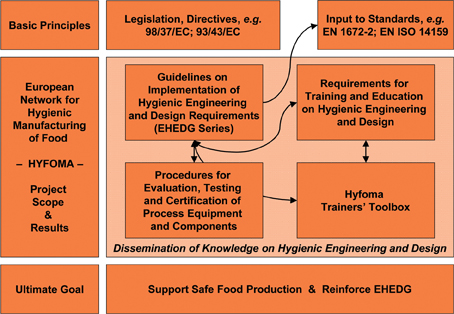

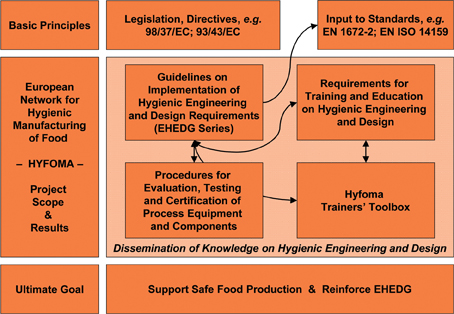

The European Network for Hygienic Manufacturing of Food – HYFOMA – was established in 2001 with the aim to provide guidelines and test methods on hygienic design and processing and to disseminate knowledge. The presentations by key stakeholders in the final project meeting, Brussels 30 November 2004, clearly showed that HYFOMA has established new and high quality standards for guidelines and for training & education.

Food production is changing to more complex, multi-component products; a longer shelf life of fresh products; less preservatives and using raw materials from all over the world – due to consumer demands. Governments and customers are imposing public (HACCP) and private (BRC, Eurep-Gap) quality control systems. More comprehensive systems are coming, e.g. ISO 22000, covering food production itself and all supplies to it: raw materials, packaging materials, lubricating oils etc. Therefore, fulfilling criteria for hygienic food production is becoming more difficult than it used to be. Science and technology are delivering a constant stream of new insights, techniques and materials for enhancing hygienic food production, with significant contribution of the EC Framework Programs. However, establishing insights to implementation in production plants is just the beginning. Insights must be translated into guidelines agreed upon by the leading experts in Europe and understandable for all those involved – including managers and operators in production plants, equipment manufacturers, construction engineers, other suppliers and food inspectors. In addition, adequate training programs must be developed.

The European Network for Hygienic Manufacturing of Food – HYFOMA – was established in 2001 with the aim to provide guidelines and test methods on hygienic design and processing and to disseminate knowledge. The presentations by key stakeholders in the final project meeting, Brussels 30 November 2004, clearly showed that HYFOMA has established new and high quality standards for guidelines and for training & education. Food production is changing to more complex, multi-component products; a longer shelf life of fresh products; less preservatives and using raw materials from all over the world – due to consumer demands. Governments and customers are imposing public (HACCP) and private (BRC, Eurep-Gap) quality control systems. More comprehensive systems are coming, e.g. ISO 22000, covering food production itself and all supplies to it: raw materials, packaging materials, lubricating oils etc. Therefore, fulfilling criteria for hygienic food production is becoming more difficult than it used to be. Science and technology are delivering a constant stream of new insights, techniques and materials for enhancing hygienic food production, with significant contribution of the EC Framework Programs. However, establishing insights to implementation in production plants is just the beginning. Insights must be translated into guidelines agreed upon by the leading experts in Europe and understandable for all those involved – including managers and operators in production plants, equipment manufacturers, construction engineers, other suppliers and food inspectors. In addition, adequate training programs must be developed.

The European Network for Hygienic Manufacturing of Food – HYFOMA – was established in 2001 with the aim to provide guidelines and test methods on hygienic design and processing and to disseminate knowledge. The presentations by key stakeholders in the final project meeting, Brussels 30 November 2004, clearly showed that HYFOMA has established new and high quality standards for guidelines and for training & education.

Food production is changing to more complex, multi-component products; a longer shelf life of fresh products; less preservatives and using raw materials from all over the world – due to consumer demands. Governments and customers are imposing public (HACCP) and private (BRC, Eurep-Gap) quality control systems. More comprehensive systems are coming, e.g. ISO 22000, covering food production itself and all supplies to it: raw materials, packaging materials, lubricating oils etc. Therefore, fulfilling criteria for hygienic food production is becoming more difficult than it used to be. Science and technology are delivering a constant stream of new insights, techniques and materials for enhancing hygienic food production, with significant contribution of the EC Framework Programs. However, establishing insights to implementation in production plants is just the beginning. Insights must be translated into guidelines agreed upon by the leading experts in Europe and understandable for all those involved – including managers and operators in production plants, equipment manufacturers, construction engineers, other suppliers and food inspectors. In addition, adequate training programs must be developed.

In 1989 EHEDG, the European Hygienic Engineering and Design Group – uniting major European food industries, equipment manufacturers and research institutes – began developing guidelines and test methods for hygienic food production. Since then, food production has undergone major changes, as indicated above. The challenge for HYFOMA was to produce high quality and up-to-date guidelines, fully tuned to the new hygienic levels in food production plants. These guidelines are published in the EHEDG series (www.ehedg.org).

In the final project meeting, results of their impact were reviewed by key stakeholders – from academia, leading food industries, equipment manufacturers, new EU member states and, finally, EHEDG – that have made the commitment and action plans to carry forward the HYFOMA ‘heritage’.

Hygiene requirements in legislation

Many directives and regulations are in place. However, the requirements are not specific enough with respect to hygiene. Most of them have no impact on machinery and its design. Apart from the Machinery Directive (98/37/EC) these regulations come from the area of consumer protection (food safety), which cannot be used to obtain guidance for the design of food processing machines. Therefore, standards and guidelines must specify the legislation, as was stated by Mr Bellin (Engineering and Standardization, Food Processing and Packaging Machinery Association VDMA, DE and secretary of CEN/TC153).

The EN standards are helpful for machines and components, although the specific standards are often not made by hygiene specialists in the food industry and therefore the lack of information on hygiene requirements is still evident. The EN ISO 14159 and the EN 1672-2 have already been influenced by the HYFOMA/EHEDG work in the past few years. The specific hygienic design of most equipment is not covered by standards. Additional guidelines are therefore still needed.

According to Mr Bellin, HYFOMA enabled the development of completely up-to-date, new and improved EHEDG guidelines that are globally unique in their comprehensive nature and overall quality. On a world wide basis, standards and guidelines issued by USA-based organisations, such as NSF and 3-A, are similar in scope although they lack the pictures and other visual aids that make guidelines developed under HYFOMA so useful in practice. In addition, the EHEDG guidelines include test methods to verify hygienic design. Ideally standards and guidelines should be harmonised world wide. The conditions set by European legislation and regulations are taken into account in the EHEDG guidelines. These European guidelines counterbalance the American based guidelines.

Mechanical engineering does not equal hygiene

Equipment design is often a compromise between performance criteria and hygiene requirements. In seeking an acceptable compromise food safety will never be put at risk. Most designers of food processing machinery are being trained on the job, as hygiene is not an obvious part of their education in mechanical engineering. Mr Lorenzen (Key Customer Director, GEA Tuchenhagen Dairy Systems GmbH, DE) pointed out that present-day engineers are becoming much more aware of the need for hygiene.

The new generation guidelines containing high quality illustrations and visual materials are very useful for equipment manufacturers. By using these new guidelines people working in the equipment manufacturing industry acknowledge the need for hygienic design. Knowing the size of a microorganism compared to the size of a crevice in product contact surfaces or welds, teaches them to understand the risk of contamination during food production. Therefore, training of this specific target group is essential.

World class hygienic manufacturing

World class hygienic manufacturing can be achieved by setting criteria, defining standards, development of guidelines, communication, exchange of experiences and training of people involved – such as cleaning and maintenance staff. This is something that food companies cannot achieve by themselves, according to Dr Wouters (Manager Foods Manufacturing Hygiene, Unilever, NL), as food production and hygienic manufacturing comprises many elements. For example, design of equipment and components, materials of construction, building/factory lay-out, cleaning and disinfection procedures and utilities.

The HYFOMA project and its guidelines have contributed considerably to the development of world class hygienic manufacturing and have improved the dialogue with SMEs, equipment and component suppliers. The independent guidelines support communication with the parties involved. Continuous development and updating of guidelines is a must. Also, procedures for testing and certification of equipment, developed in HYFOMA, serve as advice for new purchases and should therefore be reliable and of a high standard.

People must know how and why!

There is a need for making food industry employees, equipment manufacturers and the authorities aware of what hygienic design actually is and why it is important, according to Dr. Jensen (Assistant Professor Food Process Engineering, BioCentrum-DTU, DK). The individuals that should be taught are all levels of personnel: cleaners, maintainence workers, operators, sales persons, quality assurance, process and product developers, designers, installers, welders, food safety inspectors and also the management and directors of companies.

For this purpose the Guideline with ‘Requirements for training and education in hygienic engineering and design’ has been developed. Besides system requirements and qualification requirements for trainers, specific objectives for training and education in hygienic engineering and design are categorised after classified student target groups. The advantage of the approach developed is that it is linked to a set of coherent and up-to-date guidelines. Based on the training objectives a qualified trainer can compose his/her own training course. In addition to these requirements, a unique Trainers’ Toolbox has been developed, based on pictures and other visual aids provided by companies who emphasised that these supporting materials are only effective when used by qualified trainers.

A first step toward disseminating the training approach developed under HYFOMA has been taken in the training course organised in November 2004 at BOKU University in Vienna, Austria. Twenty four experts from research and industries – half of them from new EU and Mediterranean member states – have been involved in this training course and have taken the views to their countries. Although the two-day course was short, responses were very positive and both the participants and trainers learned a lot from the experience.

The representatives of both Unilever and Kraft emphasised the need for continuous improvement and training of staff. According to them, the training approach developed in HYFOMA will support internal training of QA staff, engineers, operators etc.

Knowledge transfer – filling a gap in Hungary

During the course of the project, Campden & Chorleywood Hungary decided to join the HYFOMA network. There was a need for more detailed guidelines than the current ministerial decree and also a need for guidelines to help testing and certification possibilities in Hungary.

Dr Horváth, Development Engineer at C&C Hungary, emphasised the importance of the HYFOMA project in her country. Participation of C&C Hungary could be realised thanks to co-funding provided by the Research and Development directorate of the Hungarian Ministry of Education. C&C Hungary has translated a number of guidelines and organised a seminar. Some guidelines have been supplemented with Hungarian technical and industrial references. Approximately half of the guidelines were supplemented with references to technology used in the Hungarian food industry.

Furthering HYFOMA activities

One of the objectives of HYFOMA was to establish a basis for a reinforced EHEDG organisation. Dr Freund (Director International Microbiology and Food Safety, Kraft Foods, DE, and President of EHEDG) once more explained the principal goal of EHEDG, which is to provide guidance on the hygienic engineering aspects of the manufacture of safe and wholesome food in the supply chain. HYFOMA has given a major boost to these activities, by developing more than twenty new and updated guidelines and a training approach. The annual EHEDG action plan for the renewal and updating of guidelines, will benefit greatly from the large network of experts formed by HYFOMA.

To follow up the HYFOMA training approach, EHEDG will develop a strategy for the release of the materials to qualified trainers and for conducting training course(s), including maintenance of the system and materials. Finally, the EHEDG President was happy to mention the contributions by HYFOMA in creating new regional EHEDG sections in Southern and Eastern European countries (ES, PT, PL, HU) and in attracting new organisations as EHEDG members and sponsors. These regional sections, as well as those in North West Europe, have made a significant effort in translating guidelines in their native languages.

Entering a new era

Dr Van der Kamp (chairman HYFOMA steering group, Senior Officer International Projects TNO, NL) concluded that the deliverables of the HYFOMA project plan have been met by the drafting of new and updated guidelines published in the EHEDG series and the new training approach. But HYFOMA did more.

As a response to the enlargement of the European Union with ten new Member Countries, HYFOMA has made major efforts to raise the awareness of the importance of hygienic food production in these countries. This is in addition to activities carried out to raise awareness in southern European countries.

A new generation of guidelines

HYFOMA did not just produce new and updated guidelines; it also set much higher standards in this field. The original EHEDG guidelines, based on common sense, were produced from the input of equipment suppliers and food microbiologists. The science based HYFOMA guidelines have been made by integrating this input with many more scientific disciplines, such as:

- Rheology/CFD – for flow profile characterisation in, for example, pipes and valves and in order to understand cleanability

- Materials sciences – for characterisation of surfaces (e.g. measurement of surface roughness) and for understanding properties of new materials

- Microbiology – for insights in, for example, Legionella spp and in formation and behaviour of biofilms

In fact, HYFOMA has realised a high level of integration – not only within the fields of food technology and microbiology but also far beyond, including the sciences of multi-functional materials and nano-sciences. In addition to the high scientific level of the guidelines, they have great educational value with their clarifying illustrations.

A unique approach for training

Within the plethora of training courses in food hygiene the HYFOMA approach is unique in two ways:

- Different approaches and levels of understanding have been defined for various target groups

- The training is linked to the coherent set of EHEDG Guidelines on hygienic engineering and design to support hygienic food manufacturing

It was recognised that this training approach will also be highly effective as part of the training activities of existing and new EC funded Integrated Projects, focussing on safe and hygienic food production in specific areas. With regard to other EC funded projects, HYFOMA has already created an effective working relationship with the ISEKI project, a network of Universities throughout Europe, with many participants in new EC member countries. With this link, enhancing education in the field of food hygiene has become one of the objectives of ISEKI.

Achievement through invaluable contributions

Finally, Dr van der Kamp concluded that HYFOMA has completed its ambitious tasks with the invaluable input of experts throughout Europe with a wide range of scientific disciplines; with dedicated project management by TNO and with guidance by DG Research of the European Commission.

Acknowledgement

The HYFOMA project is funded by the European Commission under the Fifth Framework Programme – Quality of Life and Management of Living Resources (QoL), Key Action 1 (KA1) on Food, Nutrition and Health (QLK1-CT-2000-01359).

Figure 1: HYFOMA Project: scope and results

Figure 2: Why do we need requirements for training and education in hygienic engineering and design? A lot of research within the area of hygiene in food processing is being carried out – however, to convey this information from laboratories to the production plants and drawing boards of designers, all personnel must be trained and educated. It is obvious to all that we would like to avoid scenarios such as fouled heat exchangers, which are a ‘perfect’ source of contamination. It is not that difficult to either avoid such hazards or to clean them sufficiently – people just have to know how and why!

Figure 3: Impression of HYFOMA training course in Vienna