Pasta: strength and structure

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 29 July 2005 | Martin G. Scanlon, Nancy M. Edwards and Jim E. Dexter | No comments yet

Every year, in various educational institutions across the globe, students compete to design and build bridges made from spaghetti strands. In most competitions, the winner is that student team whose bridge can sustain the highest load (Johns Hopkins, 2005). Clearly some elaborate design work goes into the creation of these food engineering masterpieces (Figure 1).

However, bridge building is not the only use for pasta! Many nutritious and appetising dishes can be made from various pasta structures, such as spaghetti, lasagna, gnocchetti, manicotti, capellini, fettuccine, etc. For all pasta products, the preferred primary ingredient is semolina – coarse flour made from durum wheat. Pasta can be made from common wheat (bread-making and confectionery wheat), but is perceived as inferior to durum wheat pasta and, in some countries, legislation prohibits the addition of common wheat ingredients beyond a specified small percentage in pasta. Durum wheat was originally cultivated in the Mediterranean where, today, semolina is also used for the manufacture of specialty breads and products such as couscous, bulgar and frekeh. In recent years the proportion of durum wheat used for bread-making has been increasing.

Every year, in various educational institutions across the globe, students compete to design and build bridges made from spaghetti strands. In most competitions, the winner is that student team whose bridge can sustain the highest load (Johns Hopkins, 2005). Clearly some elaborate design work goes into the creation of these food engineering masterpieces (Figure 1). However, bridge building is not the only use for pasta! Many nutritious and appetising dishes can be made from various pasta structures, such as spaghetti, lasagna, gnocchetti, manicotti, capellini, fettuccine, etc. For all pasta products, the preferred primary ingredient is semolina – coarse flour made from durum wheat. Pasta can be made from common wheat (bread-making and confectionery wheat), but is perceived as inferior to durum wheat pasta and, in some countries, legislation prohibits the addition of common wheat ingredients beyond a specified small percentage in pasta. Durum wheat was originally cultivated in the Mediterranean where, today, semolina is also used for the manufacture of specialty breads and products such as couscous, bulgar and frekeh. In recent years the proportion of durum wheat used for bread-making has been increasing.

Every year, in various educational institutions across the globe, students compete to design and build bridges made from spaghetti strands. In most competitions, the winner is that student team whose bridge can sustain the highest load (Johns Hopkins, 2005). Clearly some elaborate design work goes into the creation of these food engineering masterpieces (Figure 1).

However, bridge building is not the only use for pasta! Many nutritious and appetising dishes can be made from various pasta structures, such as spaghetti, lasagna, gnocchetti, manicotti, capellini, fettuccine, etc. For all pasta products, the preferred primary ingredient is semolina – coarse flour made from durum wheat. Pasta can be made from common wheat (bread-making and confectionery wheat), but is perceived as inferior to durum wheat pasta and, in some countries, legislation prohibits the addition of common wheat ingredients beyond a specified small percentage in pasta. Durum wheat was originally cultivated in the Mediterranean where, today, semolina is also used for the manufacture of specialty breads and products such as couscous, bulgar and frekeh. In recent years the proportion of durum wheat used for bread-making has been increasing.

Regardless of the end-use of the durum wheat semolina, its properties are critical in determining the product’s performance. This is true whether those properties confer rigidity and flexibility to the dry strand that will be used to fabricate the bridge, or whether they enable the cooked pasta to resist the cutting forces applied by our teeth so that a firm ‘al dente’ texture is imparted. In order to effectively manipulate the desired end-use performance of the pasta, the following questions should be addressed:

- What are the properties of the materials that constitute the pasta?

- How are these materials structurally organised within the pasta?

- How are these materials and structures altered by the processes used to create the pasta?

Pasta is produced by extruding dough through dies that create the desired shape, followed by drying to impart storage stability. The process conditions (e.g., work input in the mixer and pasta press, mass and heat transfer quantities and rates in the dryer) act to modify the structure and the properties of the dough in order to produce the desired product qualities. Determining whether the properties and structure of the pasta product meet customer specifications requires sound scientific understanding of the relationship between the structure of the product and its properties. This enables scientists to modify process conditions in order to manipulate that structure so that the desired pasta properties are attained.

It follows therefore, that the manufacture of a high-quality pasta product requires raw materials with the appropriate attributes and skillful processing to attain the right structure in the pasta product. However, structure in the pasta product is inherently tied up with the microstructure that exists in the durum wheat semolina. This was highlighted last year in an article on checking in pasta by Frank Manthey, North Dakota State University, New Food Issue 2, 2004. Checking is the formation of microcracks in the pasta so that it has a poor appearance and a reduced mechanical strength. Manthey’s article explained how appropriate changes in the microstructure of the semolina during drying help develop an enhanced resistance to checking.

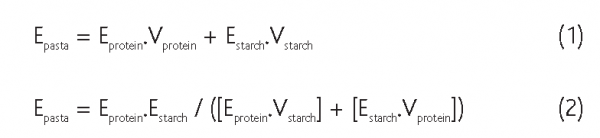

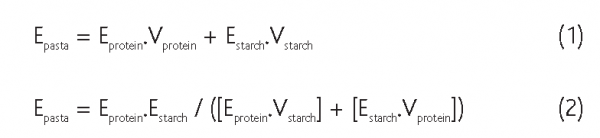

Examining the microstructure of durum wheat semolina at its simplest, shows it is comprised of starch granules embedded in a matrix of proteins (Figure 2). Starch is the major component (with a volume fraction approaching 75 per cent). It is widely accepted that the quantity and properties of the protein matrix and starch pasting properties are primary determinants of cooked pasta texture (Marchylo et al 2004). One parameter that is not apparent in Figure 2, however, has a potentially powerful influence on the properties of the pasta and that is the nature of the interface that exists between the starch granules and the protein matrix. If there is little or no adhesion, then pasta properties can be substantially different to the situation where well-bonded contact exists between granules and matrix. This is illustrated by two relatively simple equations from materials’ science (Ahmed and Jones 1990) that have been used to describe the composite material’s elastic modulus (E). The elastic modulus is a mechanical parameter that has been shown to correlate well with firmness assessed by sensory tests for many foods.

In equation 1 (the isostrain model) strong adhesion between the volume fractions (V) of the two components is assumed, while no adhesion occurs in equation 2. A difference in the modulus of the pasta composite can be observed between these two extreme cases. If we assume that we have 75% starch granules and that the modulus of the protein matrix is two-fold larger than that of the granules, simple arithmetic concludes that the pasta is 63% as ‘firm’ as the matrix when we have good adhesion (Equation 1), compared to 57% when the adhesion is poor (Equation 2). Put another way, pasta that is 10% ‘firmer’ in relative terms where adhesion is good.

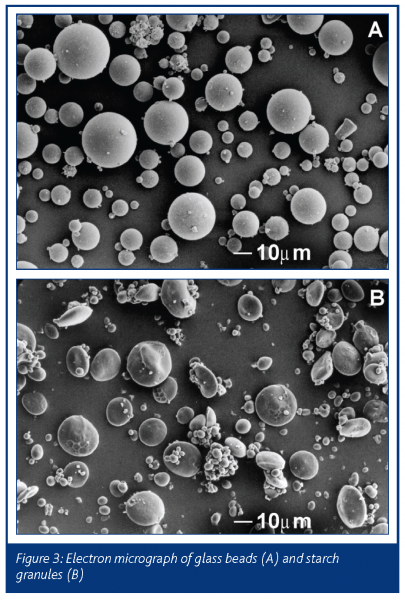

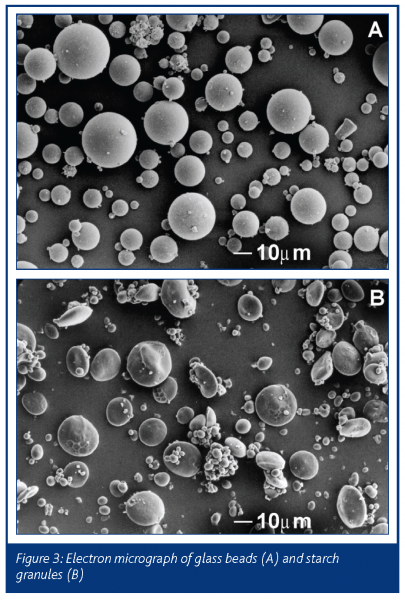

To examine the nature of the interface in durum wheat dough, starch granules were substituted with an inert filler (glass beads) of the same range in size as the starch granules (Figure 3) within a base mix of durum wheat proteins (Edwards et al 2002). These pasta composites should not be confused with vitreous or glassy durum!

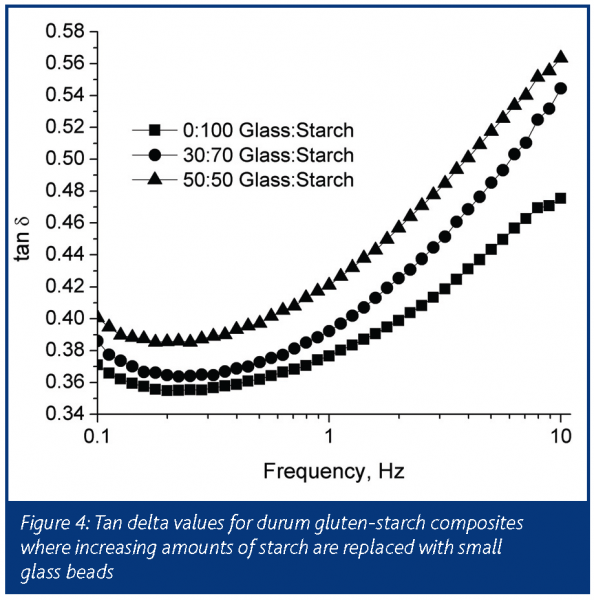

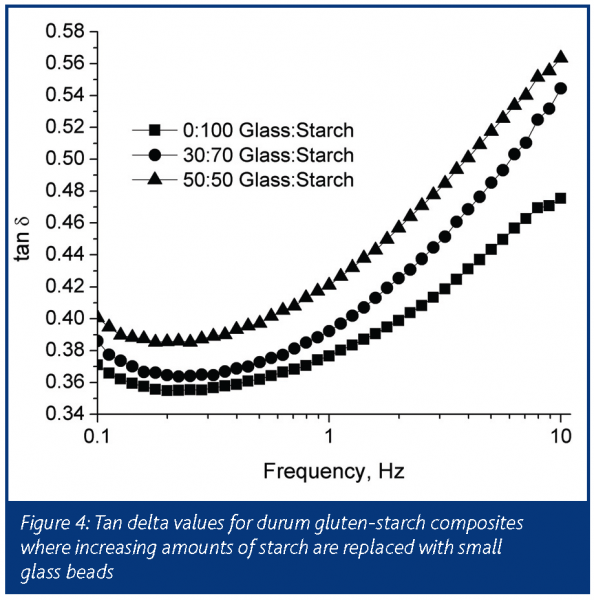

The properties of durum wheat dough were then measured through various mechanical tests. One test entailed measuring the loss tangent (tan delta) values of the durum wheat dough composites where starch granules were replaced with increasing amounts of glass beads. The tan delta values tell us how much of the strain energy that we put in when testing the sample is returned – higher tan delta values mean the sample is less elastic and more viscous. Figure 4 demonstrates that the greater the number of glass beads placed in the matrix, the higher the tan delta value. Because the smooth surface of the glass beads do not adhere well with the protein matrix, the interpretation is that less elastic properties arise in those model pasta doughs where there is less overall adhesion. This result illustrates the importance of good protein matrix-starch granule interaction in influencing the properties of the dough, which in turn determines the properties of pasta. This has implications for both wheat breeding programs and processors. Genetic pre-disposition to the production of proteins and/or starch granules that exhibit weak starch granule-protein matrix binding would be a factor hampering the manufacture of strong pasta made from such durum wheat semolina. Alternatively, the use of drying treatments that promote protein matrix-starch granule adhesion would improve the firmness of the pasta.

Although such experiments tell us about the interactions between the two major components within the pasta microstructure, one can appreciate from Equations 1 and 2 that if the modulus of the protein matrix is low, then the modulus of the pasta is low. Therefore, to comprehensively characterise pasta properties, it is also important to study the nature of the protein matrix. The predominant components within the matrix are the storage proteins. The composition and structure of these components is still a matter of debate, but it is clear that the proteins are a heterogeneous collection of monomeric (single linear strands) proteins known as gliadins and polymeric (covalently bonded branched strands) proteins known as glutenins, that are among the largest known in nature (Wrigley 1996). To gain insight into how the various protein components affect the properties of the matrix, we performed reconstitution studies using various substitutions of protein fractions from different durum wheat cultivars – some known to produce good quality pasta, others producing poor quality pasta (Edwards et al 2003).

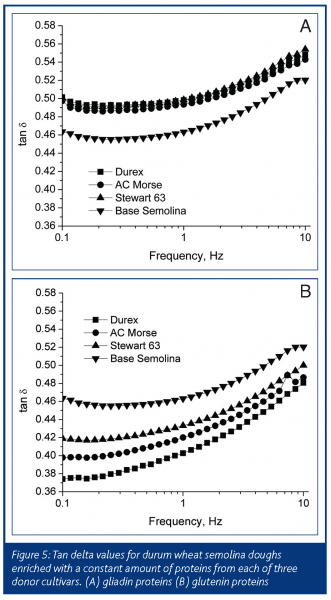

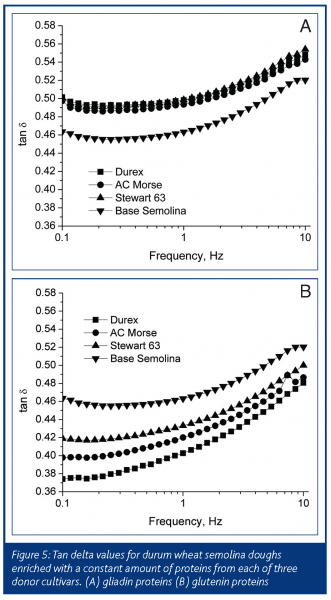

In Figure 5A, a base durum wheat semolina has had a constant amount of gliadin proteins added from different durum wheat cultivars. It is well recognised that gliadin proteins impart viscosity to dough (MacRitchie 1992) and this is evident from the higher tan delta values observed for dough when gliadin proteins are added. But, the effect of gliadin proteins on tan delta values is seen to be independent of the quality of the donor durum wheat cultivar. This tells us that gliadin proteins do not exert a differential effect on this particular property of pasta dough.

In Figure 5B a constant amount of glutenin proteins was added to the same base semolina. It is well recognised that glutenin proteins impart elasticity to dough (MacRitchie 1992). As expected tan delta of dough became lower (more elastic) when glutenin proteins were added. However, in this case donor parent does have an effect on tan delta values: a marked greater decrease in tan delta occurs when glutenin proteins from the cultivar Durex is added, compared to Stewart 63 and AC Morse gives intermediate values. When pasta is processed from these cultivars and cooking properties are measured by conventional tests, pasta made from Durex semolina ranks superior to that from Stewart 63, with pasta made from AC Morse in between. These results infer that one of the bases for the superior pasta-making ability of Durex is the nature of its glutenin proteins. Evidently, the genetic regulation of protein synthesis and deposition in the matrix carries over to influence the matrix of the pasta product, and hence the properties of that pasta. Unravelling the molecular basis for the influence of glutenin protein structure on pasta properties is a challenge that involves the use of sophisticated instruments such as mass spectrometers and complex molecular techniques (Cunsolo et al 2004; Shewry et al 2003).

Pasta properties are dependent on the nature of the raw materials and the structure created during processing. The quantity of protein affects pasta structure and cooking characteristics by determining the continuity of the protein matrix and drying conditions are well known to influence pasta properties (Marchylo et al 2004). Our results show that the interface between starch granules and the protein matrix is also an important contributor to pasta dough elasticity and, therefore, the elasticity of pasta. In addition, the properties of glutenin proteins, as determined by the genetic background of the durum wheat semolina used to manufacture the pasta, influence the elasticity of pasta dough in a manner consistent with differences in pasta cooking characteristics. Better understanding of the molecular basis for superior pasta will help breeders to develop durum wheat cultivars that will put pasta with better texture on the table. And that would be a good thing!

References

Ahmed, S. and Jones, F.R. 1990. A review of particulate reinforcement theories for polymer composites. Journal of Materials Science, Volume 25, pp. 4933-4942.

Cunsolo, V., Foti, S, Saletti, R. 2004. Mass spectrometry in the characterisation of cereal seed proteins. European Journal of Mass Spectrometry, Volume 10, pp. 359 370.

Edwards, N. M., Dexter, J. E. and Scanlon, M. G. 2002. Starch participation in durum dough linear viscoelastic properties. Cereal Chemistry, Volume 79, pp. 850 856.

Edwards, N. M., Scanlon, M. G., Mulvaney, S.J. and Dexter, J.E. 2003. Role of gluten and its components in determining durum semolina dough viscoelastic properties. Cereal Chemistry, Volume 80, pp. 755-763.

Johns Hopkins 2005. http://www.jhu.edu/virtlab/spaghetti bridge/ Accessed June 6th.

MacRitchie, F. 1992. Physicochemical properties of wheat proteins in relation to functionality. Advances in Food Nutrition Research, Volume 36, pp. 1-87.

Manthey, F. 2004. From production to purchase – strong high quality pasta. New Food, Issue 2, pp. 45-49.

Marchylo, B. A., Dexter, J. E. and Malcolmson, L. M. 2004. Improving the texture of pasta. Pages 475-500 in: Texture in Food. Volume 2. Solid Foods. D. Kilcast, ed. Woodhead Publishing Ltd, Cambridge, UK.

Shewry, P.R., Gilbert, S.M,, Savage, A.W.J., Tatham, A.S., Wan, Y.F., Belton, P.S., Wellner, N., D’Ovidio, R., Bekes, F., and Halford, N.G. 2003. Sequence and properties of HMW subunit 1Bx20 from pasta wheat (Triticum durum) which is associated with poor end use properties

Theoretical and Applied Genetics, Volume 106, pp. 744 750.

Wrigley, C.W. 1996. Giant proteins with flour power. Nature, Volume 381: 738-739.