Rapid pasteurisation of meats using radio frequency or ohmic heating

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 4 September 2007 | James Lyng, UCD Dublin, School of Agriculture, Food Science and Veterinary Medicine | No comments yet

This article introduces the use of radio frequency (RF) and ohmic (OH) heating for meat pasteurisation and gives a brief overview of some UCD Dublin findings on the quality of OH and RF cooked meats.

RF and OH vs. conventional pasteurisation of meat

In pasteurising meat, the aim is to eliminate pathogens and reduce the level of spoilage organisms to give a reasonable shelf life under subsequent refrigerated storage conditions. Another important reason for cooking meat is to induce certain chemical reactions in a product which produce the flavour, colour and texture a consumer expects in a cooked meat. Conventional industrial pasteurisation of larger meat products is generally performed in a batchwise fashion either by placing products in steam ovens or alternatively by immersion in tanks of hot water. The difficulty with solids such as meat is that heat transfer within these products is predominantly by conduction which is relatively slow. The net effect is that it is necessary to leave the product in the heating media for a relatively long period of time for the interior to heat to an appropriate temperature. Meanwhile the outer surface of the product will have reached a high temperature at a much earlier stage which can lead to overheating in this area. Both OH and RF are forms of electro heating in which electrical energy is applied to products via a series of electrodes. In contrast to conventional heating, OH and RF generate heat within the product predominantly by internal ionic friction (although in RF a certain amount of heat will also be generated by friction induced by dipole rotation). These technologies differ from each other in a number of respects including the fact that in OH, electrical energy is passed directly into a food while in RF, electrical energy is first converted to electromagnetic radiation which is then applied to the food. The practical implications of this is that RF radiation will penetrate through conventional plastic packaging (metal clips cannot be used) without any requirement for direct contact with electrodes, while in OH, the product needs to be either unpackaged, in direct contact with the electrodes and subsequently packaged, or alternatively be in a sealed pack which has conductive regions which allow electrical current into the meat. Meat products have a certain amount of ionic compounds present naturally (e.g. calcium) with others (e.g. salt, phosphates etc.) added during product manufacture. These ions are dispersed around the product relatively uniformly. Essentially what happens in an RF or OH heating system is that an electrical field with positive and negative regions is formed. Under these conditions positive ions in the product move towards negative regions of the field and negative ions move towards positive regions of the field. Heating occurs in the case of OH because this field is not static with polarity continually changing, generally at low frequencies (50 Hz in Europe or 60 Hz in USA). In RF, polarity changes at much higher frequencies (e.g. 27.12 MHz). Therefore, no sooner have ions started to move than the polarity of the electrodes swaps and ions have to move again. The net effect of all of this is that heat is generated internally by friction (thereby avoiding the lag between the surface and the centre of the product).

This article introduces the use of radio frequency (RF) and ohmic (OH) heating for meat pasteurisation and gives a brief overview of some UCD Dublin findings on the quality of OH and RF cooked meats. RF and OH vs. conventional pasteurisation of meat In pasteurising meat, the aim is to eliminate pathogens and reduce the level of spoilage organisms to give a reasonable shelf life under subsequent refrigerated storage conditions. Another important reason for cooking meat is to induce certain chemical reactions in a product which produce the flavour, colour and texture a consumer expects in a cooked meat. Conventional industrial pasteurisation of larger meat products is generally performed in a batchwise fashion either by placing products in steam ovens or alternatively by immersion in tanks of hot water. The difficulty with solids such as meat is that heat transfer within these products is predominantly by conduction which is relatively slow. The net effect is that it is necessary to leave the product in the heating media for a relatively long period of time for the interior to heat to an appropriate temperature. Meanwhile the outer surface of the product will have reached a high temperature at a much earlier stage which can lead to overheating in this area. Both OH and RF are forms of electro heating in which electrical energy is applied to products via a series of electrodes. In contrast to conventional heating, OH and RF generate heat within the product predominantly by internal ionic friction (although in RF a certain amount of heat will also be generated by friction induced by dipole rotation). These technologies differ from each other in a number of respects including the fact that in OH, electrical energy is passed directly into a food while in RF, electrical energy is first converted to electromagnetic radiation which is then applied to the food. The practical implications of this is that RF radiation will penetrate through conventional plastic packaging (metal clips cannot be used) without any requirement for direct contact with electrodes, while in OH, the product needs to be either unpackaged, in direct contact with the electrodes and subsequently packaged, or alternatively be in a sealed pack which has conductive regions which allow electrical current into the meat. Meat products have a certain amount of ionic compounds present naturally (e.g. calcium) with others (e.g. salt, phosphates etc.) added during product manufacture. These ions are dispersed around the product relatively uniformly. Essentially what happens in an RF or OH heating system is that an electrical field with positive and negative regions is formed. Under these conditions positive ions in the product move towards negative regions of the field and negative ions move towards positive regions of the field. Heating occurs in the case of OH because this field is not static with polarity continually changing, generally at low frequencies (50 Hz in Europe or 60 Hz in USA). In RF, polarity changes at much higher frequencies (e.g. 27.12 MHz). Therefore, no sooner have ions started to move than the polarity of the electrodes swaps and ions have to move again. The net effect of all of this is that heat is generated internally by friction (thereby avoiding the lag between the surface and the centre of the product).

This article introduces the use of radio frequency (RF) and ohmic (OH) heating for meat pasteurisation and gives a brief overview of some UCD Dublin findings on the quality of OH and RF cooked meats.

RF and OH vs. conventional pasteurisation of meat

In pasteurising meat, the aim is to eliminate pathogens and reduce the level of spoilage organisms to give a reasonable shelf life under subsequent refrigerated storage conditions. Another important reason for cooking meat is to induce certain chemical reactions in a product which produce the flavour, colour and texture a consumer expects in a cooked meat. Conventional industrial pasteurisation of larger meat products is generally performed in a batchwise fashion either by placing products in steam ovens or alternatively by immersion in tanks of hot water. The difficulty with solids such as meat is that heat transfer within these products is predominantly by conduction which is relatively slow. The net effect is that it is necessary to leave the product in the heating media for a relatively long period of time for the interior to heat to an appropriate temperature. Meanwhile the outer surface of the product will have reached a high temperature at a much earlier stage which can lead to overheating in this area. Both OH and RF are forms of electro heating in which electrical energy is applied to products via a series of electrodes. In contrast to conventional heating, OH and RF generate heat within the product predominantly by internal ionic friction (although in RF a certain amount of heat will also be generated by friction induced by dipole rotation). These technologies differ from each other in a number of respects including the fact that in OH, electrical energy is passed directly into a food while in RF, electrical energy is first converted to electromagnetic radiation which is then applied to the food. The practical implications of this is that RF radiation will penetrate through conventional plastic packaging (metal clips cannot be used) without any requirement for direct contact with electrodes, while in OH, the product needs to be either unpackaged, in direct contact with the electrodes and subsequently packaged, or alternatively be in a sealed pack which has conductive regions which allow electrical current into the meat. Meat products have a certain amount of ionic compounds present naturally (e.g. calcium) with others (e.g. salt, phosphates etc.) added during product manufacture. These ions are dispersed around the product relatively uniformly. Essentially what happens in an RF or OH heating system is that an electrical field with positive and negative regions is formed. Under these conditions positive ions in the product move towards negative regions of the field and negative ions move towards positive regions of the field. Heating occurs in the case of OH because this field is not static with polarity continually changing, generally at low frequencies (50 Hz in Europe or 60 Hz in USA). In RF, polarity changes at much higher frequencies (e.g. 27.12 MHz). Therefore, no sooner have ions started to move than the polarity of the electrodes swaps and ions have to move again. The net effect of all of this is that heat is generated internally by friction (thereby avoiding the lag between the surface and the centre of the product).

Objectives of UCD research in OH and RF heating

To date UCD have completed a major study on RF pasteurisation of meat and are midway through a separate project on OH. The main objectives of this research have been to develop cooking protocols to enable the impact of RF and OH on eating quality, yield and composition of cooked meat to be evaluated. Another objective was to quantify physical properties governing RF and OH interaction with meat, although these results are published elsewhere (Brunton et al. 2006, Lyng et al. 2005, Lyng and McKenna, 2007, Shirsat et al., 2004a-b, Zhang et al. 2004a, Zhang et al. 2007). Microbial analysis was also conducted, but as it was not a main objective of our investigations, results are not presented. However, they did show both technologies as being capable of comparable microbial inactivation to that attained by conventional methods. In terms of products, a range of cased meat products representative of those used by the Irish meat industry were chosen with every attempt being made to cover a broad range in terms of comminution and product diameter. The products exposed to RF cooking were Frankfurters (F), White Pudding (WP), Pork Luncheon Roll (PLR), Shoulder Ham (SH), Leg Ham (LH), Turkey (minced) (T), Beef (Biceps Femoris) without added ingredients (B-) and Beef (Biceps Femoris) with added ingredients (B+) PLR has been the only product studied with OH to date.

Cooking equipment at UCD Dublin

Control samples were generally cooked in a conventional steam oven (Kerres Showsmoker CS 350 EL 7.2 kW) though in some cases products were immersion cooked in a water bath. The basic RF (0.6 kW 50ø batch unit) and OH (3.5 kW batch unit) rigs used in these studies were supplied by CTech Ltd. (Capenhurst Technology Park, Capenhurst, Chester CH1 6ES, England) though UCD Dublin performed a considerable amount of development work on these rigs to optimise the application of these technologies to meat products. It is important to emphasise that if RF or OH are to be applied on a commercial scale, it would be most likely be on a continuous basis but for this work batch units were more than adequate.

Validating OH and RF cooking protocols

An important consideration in OH and RF pasteurisation is validation of cooking protocols, which requires establishing the location of the cold spot within a product. In our experiments cold spots were determined using a range of methods including infra-red photography, fibre optic probes and thermocouples. The thermocouples were either inserted into the meat during cooking (OH) or manufactured into jigs which were then inserted into products immediately following cooking (RF). While both OH and RF are forms of volumetric heating, data obtained showed OH and RF cooked products also had cold spots. Unlike conventionally cooked products where the cold spot was located in the geometric center; in RF or OH cooked products the cold spot was located in other regions of the product. The practical implications of uneven temperature distribution within RF and OH cooked products is that while both are volumetric with linear temperature profiles, there will still be different heating rates at different points in the product.

In Ireland, the extent to which products are cooked by the meat industry tends to be dictated by a series of guidelines issued by the Food Safety Authority of Ireland (FSAI). These guidelines specify that the cold spot of a product should be heated to a temperature of 70°C or more for 2 minutes or equivalent. A target temperature in the cold spot of 73°C or more for 2 minutes (which is slightly greater than FSAI Guidelines) was chosen. In this study the RF oven was set to a max output of 0.5 kW, which is very low power relative to the more powerful units that would be used commercially. However, even at this low power, RF cooking times were on average 29 per cent of steam cooked samples. A more powerful 3.5 kW OH unit was used and heating times to target temperatures were as low as 2 per cent of conventional times.

Yield and composition of OH and RF cooked products

In comminuted products, no yield difference was noted between conventional and RF or OH cooked samples. However, for non-comminuted products (i.e. ham and beef, only studied under RF conditions to date), in all cases RF cooked products had higher yields than steam cooked products. The difference was about 1-1.5 per cent in the case of ham and 4-6 per cent in beef. Following on from this, proximate analysis showed that the general trend was for the RF cooked products to have a higher moisture and lower protein and fat contents. OH PLR also followed this trend. As products cook, proteins such as myosin and collagen denature and lose water. The observed results may be indicative of less heat induced protein denaturation (and associated water loss) in the more rapidly heated products which manifests in higher yield. However, this is just a theory and more in depth studies would be required to specifically explore this.

Quality of RF cooked meats

It is important to emphasise that the results presented are a summary of a large number of experiments conducted by many different individuals on many different products (Brunton et al. 2005, Lyng et al. 2007, McKenna et al. 2006, Tang et al. 2005, Tang et al. 2006, Zhang et al. 2004b, Zhang et al. 2006). This section attempts to bring all this information together with no aspect described in great detail. The quality attributes examined were texture, colour and flavour.

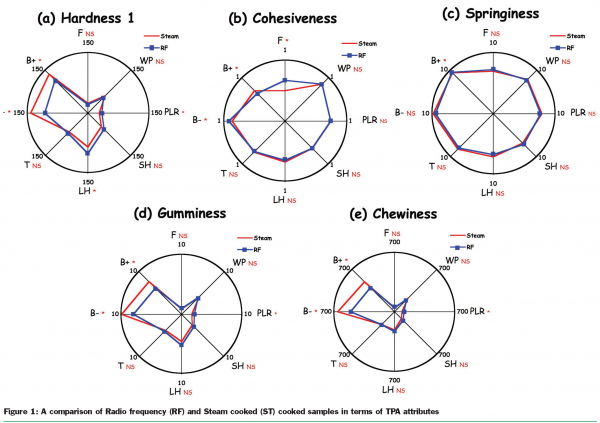

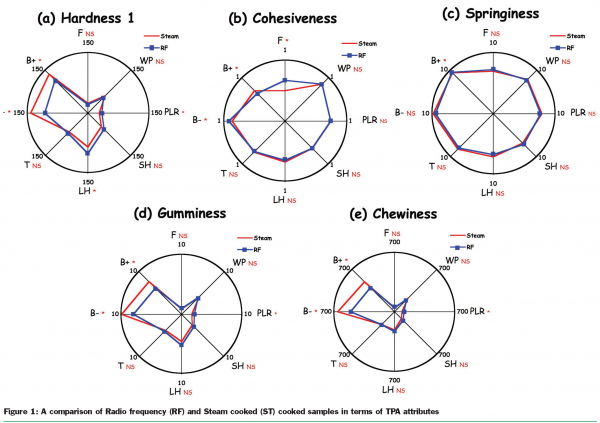

Texture of RF cooked meats

While a range of instrumental texture measurement techniques (including Warner Bratzler, Kramer Shear and Penetrometer) were used, only the results from texture profile analysis (TPA) will be presented. Results for all products are presented on spider diagrams with each product denoted by an abbreviation at the circumference (e.g. F: frankfurters; WP: white pudding etc.). The TPA attribute hardness (Figure 1a) will be used as an example for illustrative purposes. The centre of the spider represents the lowest possible value while the circumference represents highest value (150 N in the case of Hardness 1). If products are compared, results show the B+/- used in this work has higher hardness than F, while WP was harder than F etc. When cooking methods are compared, the graph shows no definite trend. RF and steam cooked F, WP, SH, T samples were not significantly different from each other (P>_0.05), in PLR and LH the RF cooked samples were harder (P<0.05) than steam cooked, while for B the opposite was the case (i.e. steam cooked were harder than RF cooked (P<0.05)). As regards cohesiveness, steam and RF cooked WP, PLR, SH, LH and T were not significantly different from each other (P>0.05), RF cooked F and B-, were higher than ST, the RF cooked B+ was lower than steam. Similarly for springiness, no significant difference (P<0.05) was observed between RF and steam cooked products, except B+, where RF was slightly higher than steam cooked. For gumminess, no significant difference was obtained between RF and steam cooked F, WP, SH, LH and T, though in PLR RF had higher (P<0.05) gumminess than ST, while RF cooked B+/- had lower gumminess than conventionally cooked. Finally for chewiness, significant differences were noted in PLR (RF was higher (P<0.05) than conventionally cooked) while for B+ and B- the RF was lower (P<0.05) than conventionally cooked).

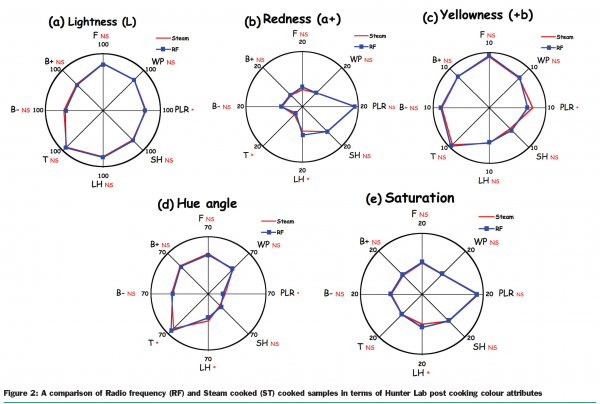

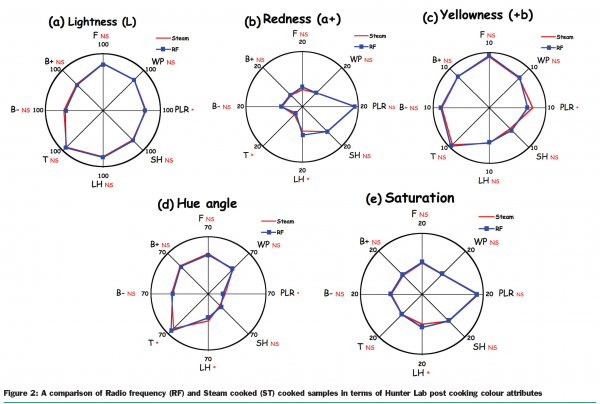

Colour of RF cooked meats

A Minolta colorimeter was used to measure colour and results were presented using the Hunter Lab colour space. Figure 2 gives an overview of the findings. In terms of lightness (L), as expected, T (white meat) has the highest L values, followed by LH and F with B+ and B- being the darkest. The results for RF cooked samples are virtually identical to steam cooked with PLR being the only product where significant differences were evident. When products are compared in terms of redness (a+), the influence of an artificial colouring (E128 (i.e. Red 2G)) is evident in PLR samples. Again when RF and steam cooking protocols are compared, no definite trends are evident. Where significant differences in redness did occur, results were once again conflicting with RF cooked LH having higher a+ values, while in contrast steam cooked T had higher a+ values than RF cooked. Results for yellowness (b+), hue angle and saturation are also presented. Overall, RF and steam cooked samples were reasonably similar with some significant differences but no definite trend is evident in any of the colour attributes assessed.

Flavour of RF cooked meats

Various instrumental flavour analyses were conducted on a number of different products. Some work was conducted using a gas chromatograph while other work involved the Tbars test. Differences were noted though they were very slight and unlikely to have an impact on sensory analysis. Rates of oxidation in beef and turkey were slightly less in RF compared to steam cooked but the magnitude of this difference was so low that it was unlikely to be detected by sensory analysis. In addition, no major differences were noted in sulphur volatiles in RF vs. steam cooked samples (containing meaty aroma).

Quality of OH cooked meat products

UCD results for the quality of OH heated comminuted meat products vs. conventionally cooked products are presented by Shirsat et al. (2004c) for 1 kg ohmically cooked (at voltage densities ranging from 3-7 V cm-1) cooked to standardised values or to target end point temperatures. Not surprisingly higher ohmic voltage densities produced faster heating rates.

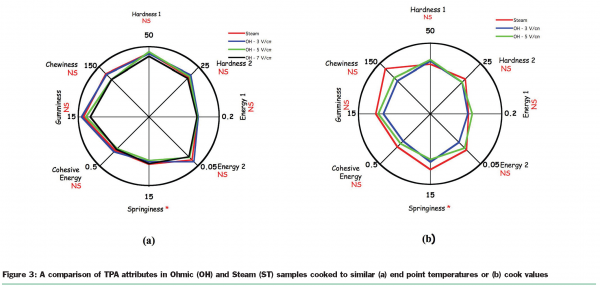

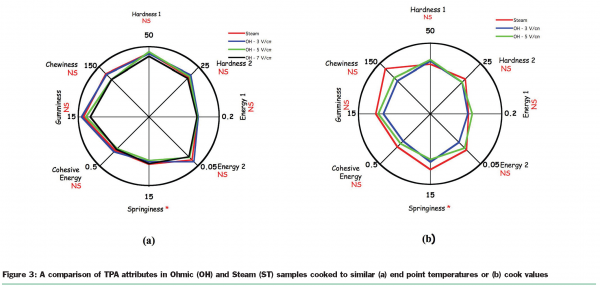

TPA of ohmic and steam cooked frankfurter batter (Figure 3) showed no significant difference (P≥0.05) in any of the attributes assessed (hardness (1 and 2), energy (1 and 2), cohesion energy, gumminess and chewiness) with the exception of springiness, which was significantly lower (P<0.05) in OH cooked samples heated to similar cook values though this trend was less pronounced in samples cooked to similar end point temperatures. Sensory analysis on ohmic and steam cooked samples cooked to similar end point temperatures supported these observations with regard to texture.

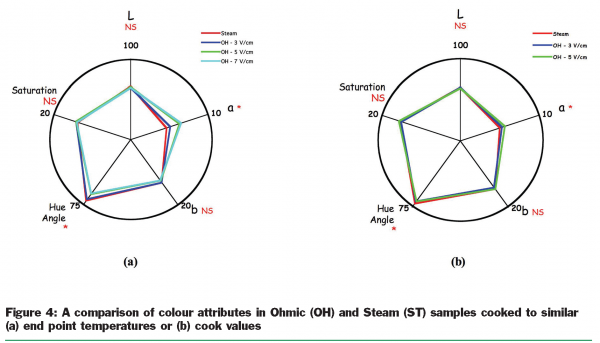

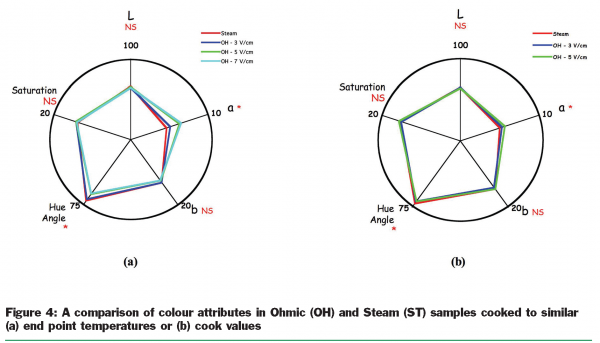

Instrumental colour evaluations (Figure 4) revealed OH cooked samples (cooked both to similar cook values or end point temperatures) differed from steam cooked in both a* and hue angle values (P<0.05) with these differences being less pronounced in samples cooked to similar cook values. These differences were small and were not likely to be detected by consumers.

Conclusion

Overall, when product quality in OH and RF cooked meats was compared to conventional cooking no differences were detected in many products/attributes. Where differences were noted they were generally subtle and it was not possible to tell whether these differences were due to the heating mechanism or the extent of heating. Results suggest that RF cooking is certainly capable of producing meat products that are of comparable quality to conventionally cooked samples while non-comminuted meat products are likely to have a higher yield compared to conventionally cooked samples. In relation to OH, further work is still ongoing for a broader range of meats though initial results look promising.

Acknowledgement

This research was funded by the Food Institutional Research Measure administered by the Department of Agriculture and Food Ireland under the National Development Plan.

References

Brunton, N, Lyng, JG, Wenqu Li, Cronin, DA, Morgan, D & McKenna, B (2005). Effect of Radio Frequency heating on the texture, colour and sensory properties of a comminuted pork meat product. Food Research International 38, 337-344.

Brunton, N, Zhang, L & Lyng JG (2006). The use of dielectric properties and other physical analyses for assessing protein denaturation in beef biceps femoris muscle during cooking from 5 to 85°C. Meat Science, 72, 236-244.

Lyng, JG, Zhang, L & Brunton, N (2005). A Survey of the Dielectric Properties of Meat and Ingredients used in meat product manufacture. Meat Science, 69, 589-602.

Lyng, JG, Cronin, DA, Brunton, NP Li, W & Gu, X (2007a). An examination of factors affecting radio frequency heating of an encased meat emulsion. Accepted for publication in Meat Science.

Lyng, JG & McKenna (2007). Ohmic pasteurisation of meat and meat products. In: Food Machinery Design Handbook: Farming, Processing, and Packaging, Myer Kutz (ed.), William Andrew, Inc., 553–578.

McKenna, BM, Lyng JG, Brunton, N & Shirsat N (2006). Advances on radio frequency and ohmic heating of meats. Journal of Food Engineering 77(2), 215-229.

Shirsat, N, Lyng, JG, Brunton, NP, & McKenna B (2004a). Ohmic processing: Electrical conductivities of pork cuts. Meat Science, 67, 507-514.

Shirsat, N, Lyng, JG, Brunton, NP & McKenna B (2004b). Conductivities and ohmic heating of meat emulsion batters. Journal of Muscle Foods, 15, 121-137.

Shirsat, N, Brunton, NP, Lyng, JG, McKenna B & Scannell, A (2004c). Texture, colour and sensory evaluation of a conventionally and ohmically cooked meat emulsion batter. Journal of the Science of Food and Agriculture, 84, 1861-1870.

Tang, X Cronin, DA & Brunton, NP (2005). The Effect of Radio Frequency Heating on Chemical, Physical and Sensory Aspects of Quality in Turkey Breast Rolls. Food Chemistry, 93, (1), 1-7.

Tang, X Lyng, JG, Cronin D & Durand C (2006). Radio frequency heating of beef rolls from biceps femoris muscle. Meat Science 72, 467-474.

Zhang, L, Lyng, J, Brunton, N, Morgan, D & McKenna B (2004a). Dielectric and thermophysical properties of meat batters over a temperature range of 5-85°C. Meat Science 68(2), 173-184.

Zhang, L, Lyng, J & Brunton, N (2004b). Effect of Radio Frequency Cooking on the Texture, Colour and Sensory Properties of a Large diameter Comminuted Meat Product. Meat Science 68(2), 257-268.

Zhang, L, Lyng, JG & Brunton N (2006). Quality of Radio Frequency Heated Pork Leg and Shoulder Ham. Journal of Food Engineering, 75(2), 275-287.

Zhang, L Lyng, JG & Brunton, N (2007). The effect of fat, water and salt on the thermal and dielectric properties of meat batter and its temperature following microwave or radio frequency heating. Journal of Food Engineering 80(1), 142-151.