Testing NIR Spectroscopy for drip loss prediction

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 28 February 2008 | Marjeta Candek-Potokar, Agricultural Institute of Slovenia and Maja Prevolnik, University of Maribor, Faculty of Agriculture, Maribor, Slovenia | No comments yet

Meat quality has many different meanings. To some, quality refers to aspects of the carcass in respect to weight, fat cover and distribution, muscling/conformation and bruising. To others, quality refers to aspects such as chiller assessment attributes ie. meat colour, intermuscular fat colour and marbling. In pork, the attention of both industry and consumers is largely focused on the water holding capacity of meat.

Meat quality has many different meanings. To some, quality refers to aspects of the carcass in respect to weight, fat cover and distribution, muscling/conformation and bruising. To others, quality refers to aspects such as chiller assessment attributes ie. meat colour, intermuscular fat colour and marbling. In pork, the attention of both industry and consumers is largely focused on the water holding capacity of meat.

Meat quality has many different meanings. To some, quality refers to aspects of the carcass in respect to weight, fat cover and distribution, muscling/conformation and bruising. To others, quality refers to aspects such as chiller assessment attributes ie. meat colour, intermuscular fat colour and marbling. In pork, the attention of both industry and consumers is largely focused on the water holding capacity of meat.

There are many methods for water holding capacity estimation, including drip loss, cooking loss, filter paper and centrifuge force. Although these methods are rather simple, they are time consuming and destructive, and very often not well correlated. Moreover, they are not practical for use at industrial level. With the exception of the pH value, no other indicator of meat quality is commonly used within the industry. The pH value itself does not offer complete information regarding the capacity of meat retaining water. Pig producers are paid on carcass leanness (meat quantity). Knowing that there is an antagonism between meat quality and quantity, it would be of great interest to procure a method of meat quality evaluation at an industrial level. Near infrared spectroscopy (NIRS) has been proven to have great potential for many applications within the food industry. The central idea was to compare the prediction of drip loss, based on NIR spectra, to the pH and colour measurements (Minolta L*, a*, b*). We also tested the effect of different chemometric approaches on the predictive ability of NIRS, with special emphasis on the use of artificial neural network (ANN).

Reference method for drip loss determination

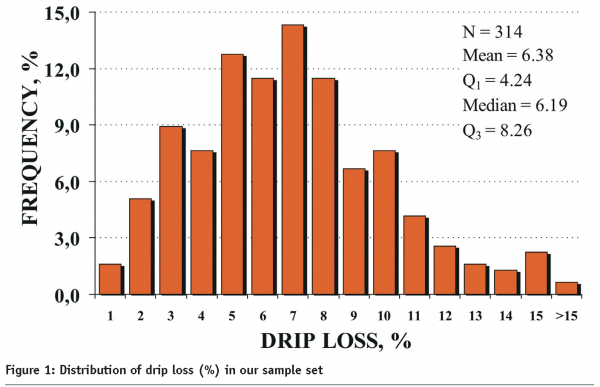

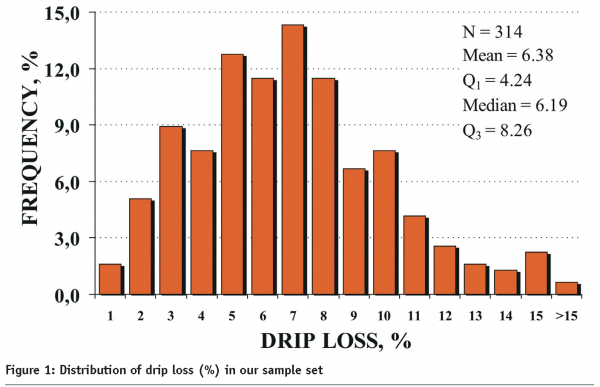

\EZ drip loss method, according to Christensen (2003), was applied as the reference method of drip loss determination. In our study, we concentrated only on longissimus dorsi muscle. Figure 1 shows the distribution of drip loss in our sample set. The accuracy of the EZ drip loss method (our reference method) was determined as the repeatability between two replicates i.e. as the standard deviation of the difference between replicates, and was in our case 1.3%1.

Different input data/descriptors

Many literature reports demonstrate the benefits of NIR spectral information for meat analysis, but studies dealing with the ability of NIRS, to predict pork technological quality, are not numerous. First of all they show that the results vary considerably between the studies and secondly, that the use of NIRS for meat quality evaluation gives less promising results than in the case of meat composition (chemical analysis). Moreover, in some of the published studies, alternative fast and simple measurements (only correlated to drip loss) were used, e.g. pH, Minolta L*. Therefore, we pursued two aims; firstly to examine prediction models for drip loss, based on simple measurements of pH and Minolta L*, a*, b* values and secondly, to compare this prediction to the one based on NIRS spectra. The prediction models were made using spectra, obtained with spectrophotometer NIR Systems 6500 (Silver Springs, MD, USA) and WinISI II software with PLS regression.

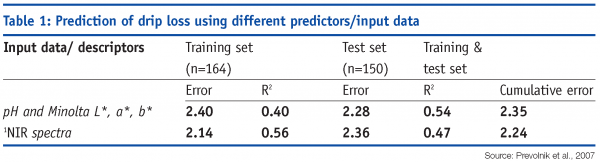

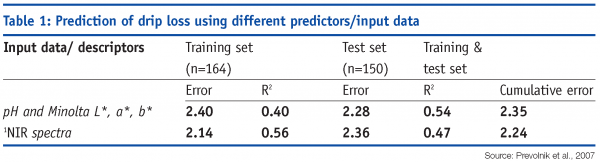

The results regarding prediction ability of drip loss, based on different input data, are shown in Table 1. The accuracy of calibration was slightly greater in case of NIR spectra, whereas the prediction ability was comparable, whether drip loss was predicted from measurements of pH and colour (Minolta L*, a*, b*), or if the prediction was based on NIR spectra. The error of prediction based on NIR spectra seems relatively high (~2.4%), however, this error should be considered in view of the accuracy (repeatability of repetitions) of the reference method which was 1.3%. Namely, the accuracy of NIRS is limited by the accuracy of the reference method to which it is calibrated (Monin, 1998). The dependence on the reference method is not the only reason for high error of prediction. There are also other factors like the measurement site and sampling location that contribute to the uncertainty. Taking into account the aim of our study, the use of spectral information is of practical importance since NIRS has the potential for on-line application2.

Different chemometric approach

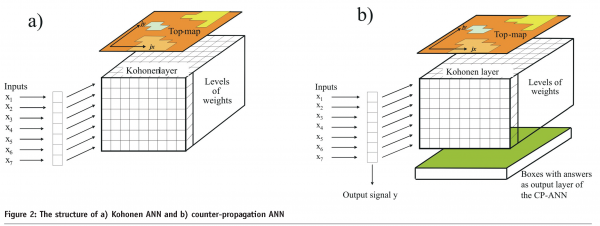

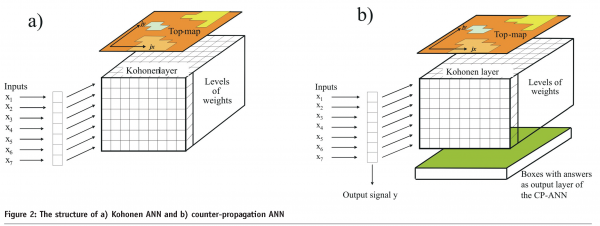

The relationship between drip loss and applied predictors is not perfect and not linear. Applied indicators (measured parameters) explain only partly the variation of such complex trait as drip loss. Therefore, the use of an alternative chemometric approach could be useful. We tried to improve prediction ability by using a novel approach, i.e. using artificial neural networks (ANN). Among various types of ANN, Kohonen and counter-propagation ANN (CP-ANN) were applied in our study.

The Kohonen ANN (Figure 2a), also known as self-organising maps, belong to the unsupervised strategy of learning. The main goal of this method is to map objects from m-dimensional into 2-dimensional space on the basis of input data. In our study, Kohonen ANN assisted to split the samples into two adequate sets of objects (training and test set). The counter-propagation ANN (Figure 2b) belong to the supervised strategy of learning and represent an up-grade of unsupervised Kohonen ANN. Counter-propagation ANN is capable of the prediction of unknown samples. Besides input data counter-propagation, ANN requires additional layer of neurons called the output layer which is the property associated with individual sample. In our study, the counter-propagation ANN were applied to build the models for drip loss prediction.

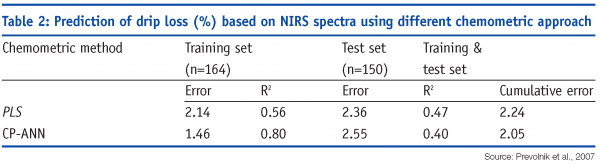

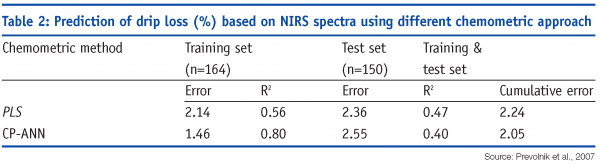

Different models for drip loss prediction were derived varying the net parameters (number of epochs and net size), but the differences in prediction ability between them were not substantial (testing error 2.55 – 2.99% and R2 0.21 – 0.40). For details of the study, please refer to the congress presentation of Prevolnik et al. (2007). The results of the best prediction model are shown in Table 2. The statistical parameters, obtained in case of PLS regression and counter-propagation ANN, show comparable ability for drip loss prediction. The error of prediction of unknown samples was 2.55% in case of counter-propagation ANN and 2.36% in case of PLS method. Cumulative errors, as indicators of overall model ability, were 2.05% and 2.24% in case of CP-ANN and PLS, respectively. Due to the improved calibration (training) ability, the cumulative error of CP-ANN is 0.2-0.3% lower, compared to PLS regression3.

Conclusion

In our opinion, NIRS represents a potential for drip loss determination at industrial level, in spite of notable uncertainty of prediction, which is largely affected by low repeatability of the reference method plus, alternative uncontrolled factors like sampling and measurement location. Further research would be valuable in relation to different reference methods and/or measurements but also in relation to different chemometric approaches. Perhaps for industrial use, a classification might turn out to be more practical. Furthermore, these results were obtained using a laboratory spectrometer which means that field instruments should be tested.

Acknowledgement

The results presented in this article are extracted from a congress presentation (Prevolnik et al., 2007) and were obtained within the project, L4-6376, co-funded by the ministries of the Republic of Slovenia, responsible for science and agriculture.

References

- Christensen L.B. (2003). Drip loss sampling in porcine m. longissimus dorsi. Meat Sci. 63: 469-477.

- Monin G. (1998). Recent methods for predicting quality of whole meat. Meat Sci. 49, 231-243.

- Prevolnik M., Candek-Potokar M., Novic M., Skorjanc D. (2007). An attempt to predict meat drip loss by means of artificial neural networks. Book of abstracts of the 6th International Symposium on the Mediterranean Pig, October 11 – 13, 2007, Capo d’ orlando, Messina,, Italy, p. 72.