Novel(Q) robotics to handle food – sensitive and hygienic grippers

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 13 June 2008 | Anders Pettersson, SIK | No comments yet

In 2006, at the Institute for Food and Biotechnology, SIK, in Gothenburg, a research project was started as a part of NovelQ1. The focus of this project is to develop a robot workstation with high flexibility and hygiene that can handle soft, variable and fragile products; in other words, to handle non packaged food products.

In 2006, at the Institute for Food and Biotechnology, SIK, in Gothenburg, a research project was started as a part of NovelQ1. The focus of this project is to develop a robot workstation with high flexibility and hygiene that can handle soft, variable and fragile products; in other words, to handle non packaged food products.

In 2006, at the Institute for Food and Biotechnology, SIK, in Gothenburg, a research project was started as a part of NovelQ1. The focus of this project is to develop a robot workstation with high flexibility and hygiene that can handle soft, variable and fragile products; in other words, to handle non packaged food products.

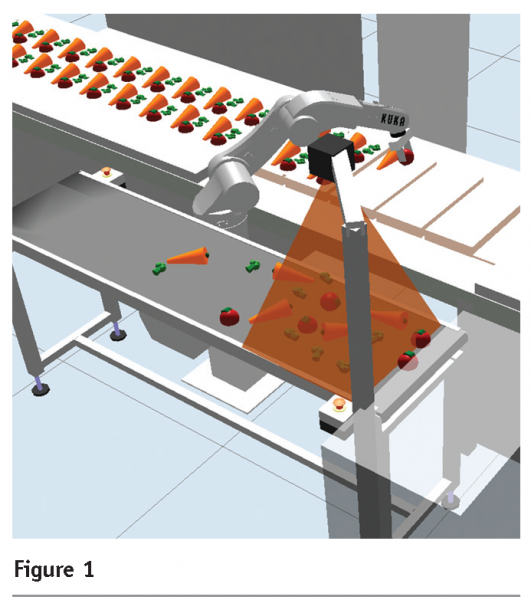

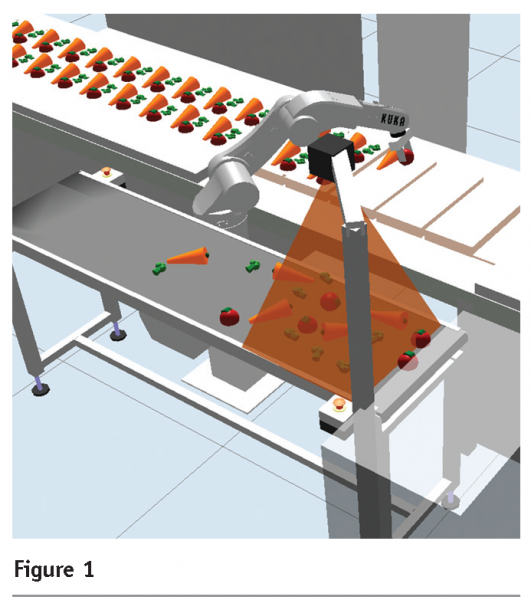

Carrots, tomatoes, broccoli, apples and strawberries were selected as test targets, as they span a wide range of shapes, textures and fragility. The aim is to be able to handle the test products, arriving in a disorderly and mixed manner, so that they leave the workstation neatly ordered in trays as shown in the visualisation in Figure 1.

Do we need more robots in the food industry?

Today, consumers demand a large product selection to choose from, and a continuous supply of new products in the food stores. This demand can be difficult to meet using a traditionally automated line2. However, a production line consisting of two robots, each equipped with a general purpose gripper, would, in theory, be able to handle a range of products, meaning, for example, that a wide variety of ready meals could be produced on the same line. The time lost when changing recipes would be minimal, it would even be possible to produce multiple recipes at the same time3! Robots do have other advantages as well, such as being able to work in both chilled and modified atmospheres, continuously and around the clock. Furthermore, manual labour adds an extra source of product contamination whereas properly designed automation can instead lead to greatly improved hygiene and product quality.

Why aren’t there more out there then?

Food products are difficult to handle for a robot, as every single product is different from the last. Even when handling one variety of apples, no two apples have the same shape, texture, hardness or ripeness. A traditional robot gripper uses either a pre set force, or it needs to know the products dimensions to a high accuracy. Usually these are specially designed for only one product type. Speed and robot cost have been a problem. However, robot costs are decreasing and speeds are continuously increasing, reducing the obstacles for investment. Still, the available robot grippers don’t fulfil the need for the generic handling of irregular foods. Humans, on the other hand, easily perform all these tasks with a low investment cost4. To make robotic automation attractive to food processors, it has to have the flexibility to be able to quickly switch between wide ranges of simple, repetitive tasks. To increase this flexibility, this project will focus on the development of a novel, general purpose food gripper.

Building a robot station

To be able to demonstrate and test the grippers in a realistic setting, a complete robot station has been built. For maximum flexibility, an articulated arm robot (KUKA KR5sixx) was chosen. This robot has a high degree of movement freedom, making it suitable for gripper evaluation and development. A conveyor belt is used to present the products to the robot and a vision system (Cognex In-Sight 5400) is used to identify product positions (Figure 2, food robot work station). Coordination of vision camera data, conveyor movement and robot movements is handled by a standard PC. The PC is also used for communication with the microcontrollers used with the prototype grippers.

Robot grippers – the real challenge

The challenge of the project is to design grippers that can handle the target products. At the beginning of the project, some essential food gripper features were specified:

- Delicate handling – some of the products are very soft and fragile

- Versatile – every pick operation will be different

- Optimised for food – various shapes, 0-1000g, no bruising allowed

- Short cycle times – food factories have a high throughput

- Position, orientation and applied force – these must be known to avoid damage and to be able to place the product correctly every time

- Hygiene – the hygiene should be improved compared to manual handling

In recent years, quite a lot of new grippers have been developed for handling food products. Some are ingenious like the Silsoe5 gripper that uses retractable films on the gripper fingers for handling sticky objects. Also, the Cryo gripper6, which freezes the product to it and the non contact Bernoulli gripper7 have impressive performance. However, there is still a need for more general grippers meeting the criteria above, and three novel gripper designs are therefore proposed below.

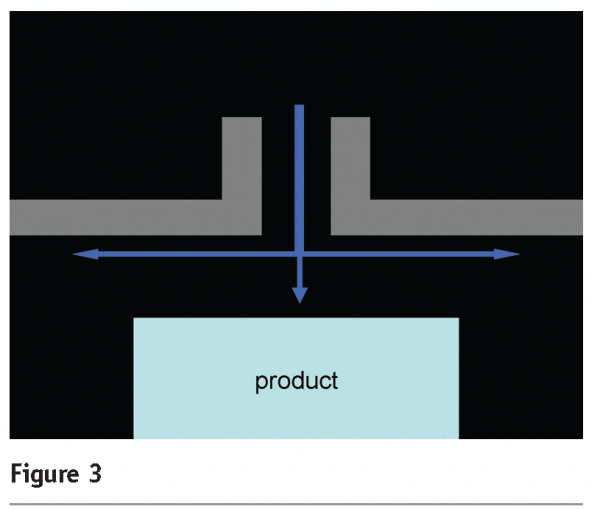

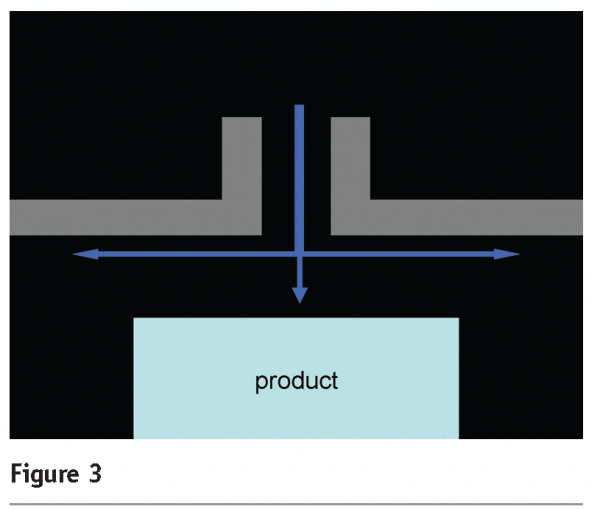

Using the Bernoulli Effect – in 3D

The Bernoulli Effect has been proposed and tested for use in grippers, for example to lift silica wafers8 in IC manufacturing and the handling of tomato slices7. A lifting force is created by a high speed air flow created in the narrow gap between the products top surface and the gripper’s bottom surface (Figure 3, basic Bernoulli gripper). With a high flow speed, an under pressure, described by the Bernoulli equation, is created in the gap generating the lifting force. Due to the repulsive force caused by the central air jet impacting with the product, it will never reach the gripper surface, but will instead float at an equilibrium distance, creating a non contact gripper. Previously, this method has only been used for lifting flat objects. In this work, a Bernoulli gripper for 3D objects is demonstrated. Unlike previous designs which consist of a flat gripping surface, the new gripper is able to deform to the shape of the object to be grasped. The gripper consists of a “pin board” covered by a thin rubber sheet, which when gently pressed against the product, shapes itself to the products contours. This shape is then locked by activating locking bars, the gripper is then lifted slightly, creating the necessary gap and the airflow is turned on, creating the lifting force (Figure 4 shows a picture sequence of an early prototype gripper conforming to the shape of an object (fingers) 4a, 4b locking the shape and 4c shaping complete – see pages 60-61). By reshaping the gripper for each new grasp, a range of products can be handled. The gripper has a number of advantages. No particles can be sucked up into the tubing where they could clog the system or cause bacterial growth as a positive supply pressure is used. Only a small force is exerted onto the products during shaping. However, unlike traditional Bernoulli grippers, the non contact feature is lost as brief contact must be made during the shaping.

A gripper sensing the force

The second gripper design uses force sensing. This is not a very novel approach for a gripper and such systems have been available for some time. The main difference in this project is the focus on high speed, low weights and hygienic design. A two fingered parallel jaw gripper equipped with strain gauge sensors for force measurement has been developed. To facilitate and speed up the gripping procedure, all available pre-knowledge will be used. When a target product is identified by the vision system, some basic properties can be extracted. When, for example, an apple is identified by the vision system, an initial diameter can be extracted from a database and used to set the initial jaw separation and the grip distance above conveyor, since the diameter is approximately the same as the height. Furthermore, by identifying the type of product, information such as friction and hardness can also be retrieved from the database. Product yield stress can then be used to estimate a maximum gripping force to avoid forces that would otherwise cause permanent damage. The strain gauge sensor approach used makes a very slim design possible, allowing picking and placing in narrow spaces. In this project, a stepper motor, ball screw and linear bearing design have been chosen. Cleaning problems associated with this are addressed in the hygienic considerations section of this paper.

Utilising the MR fluid effect

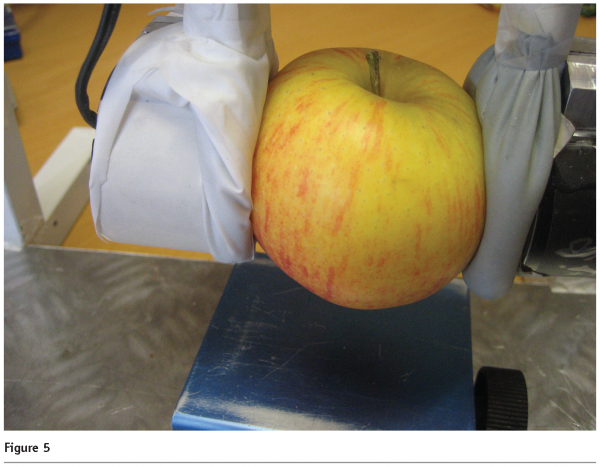

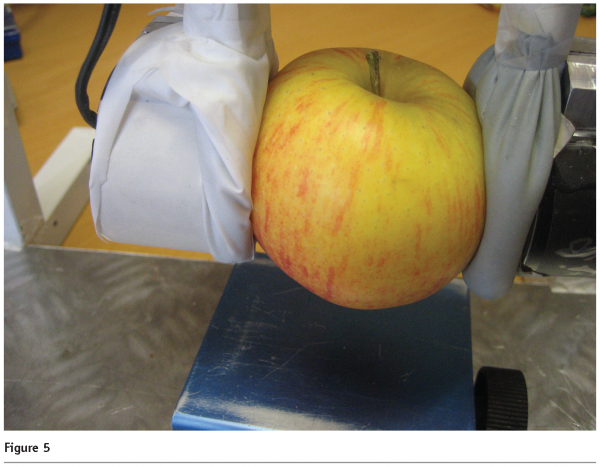

An MR fluid is iron powder suspended in oil. This fluid behaves very interestingly; when exposed to a magnetic field, its yield stress increases and it will change from being a quite low viscosity fluid into something with a viscosity similar to peanut butter. This behaviour is used to, with almost no stress, grip a product. A parallel jaw gripper is again used but on the lower part of the jaws, two opposing electromagnets have been placed. On the magnet surfaces, rubber bags filled with MR fluid have been mounted, as shown in Figure 5 (see page 61). A grip is produced as follows:

- The robot positions the gripper arms on each side of the target product

- The arms move towards the gripper surface and the “bags” containing the MR fluid, flows out around the product surface

- When the magnet is almost at the product surface, the arms are stopped and held in position

- Now the magnets are switched on, the MR fluid solidifies around the product, and it is “locked geometrically” within the perfect mould created by the solidified fluid

The robot can now lift the gripper and the product will be lifted as well, with only a minimal force exerted on to its surface.

Where do the hygienic considerations show?

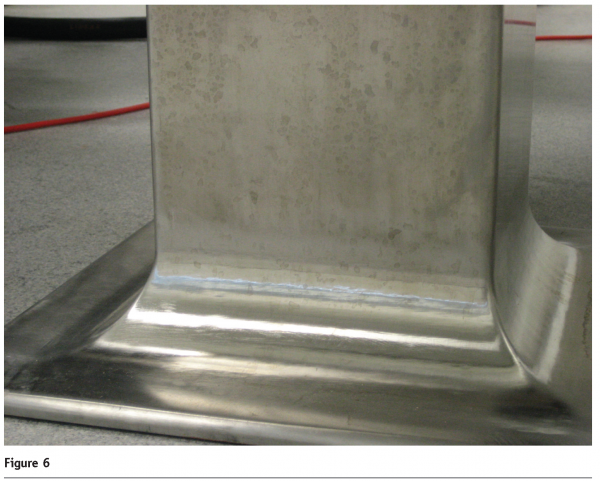

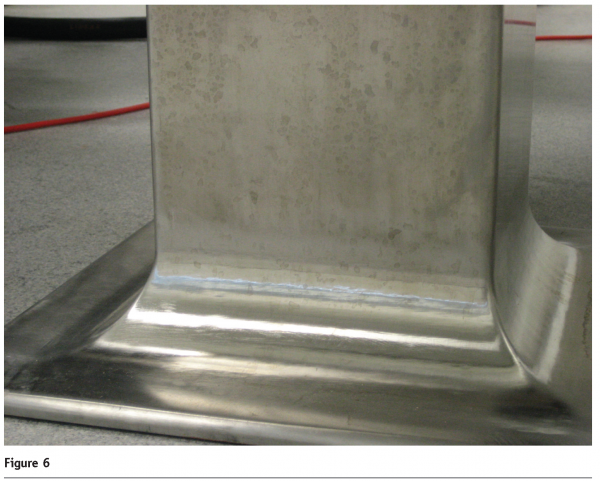

Throughout the project, equipment and designs have been chosen to achieve a good hygienic design of the robot work station. Of course, economical tradeoffs have been made to remain within a reasonable budget. Although the price of stainless steel robots is dropping, they are still relatively expensive. Instead, a standard robot has been used that will be fitted with a cover so it can be cleaned. The stainless steel stand has been designed with large radius corners at the base to improve run off and facilitate cleaning (Figure 6). On the conveyor, round profiles are used for the horizontal support beams and the vertical legs have slanted tops to improve run off and to avoid collection of dirt (Figure 7). A one-piece belt support plate is used to reduce welding, where dirt otherwise can be collected. Using a motor that is incorporated within the end roller (IP67), the number of parts to clean has been reduced. The vision system camera is mounted above the conveyor and is stainless steel encased (IP67).

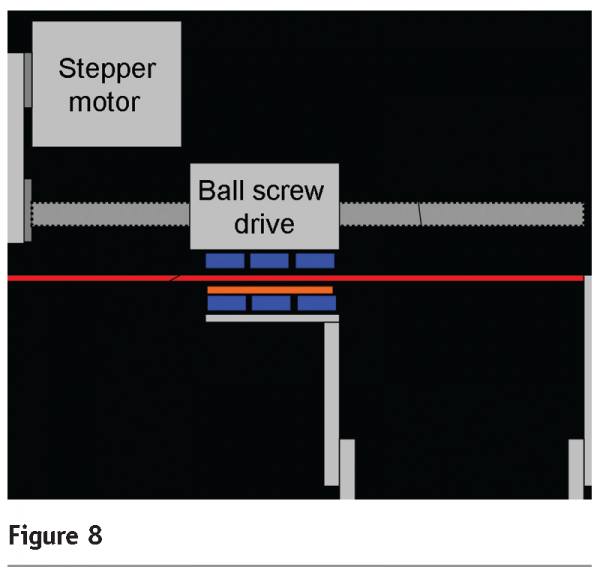

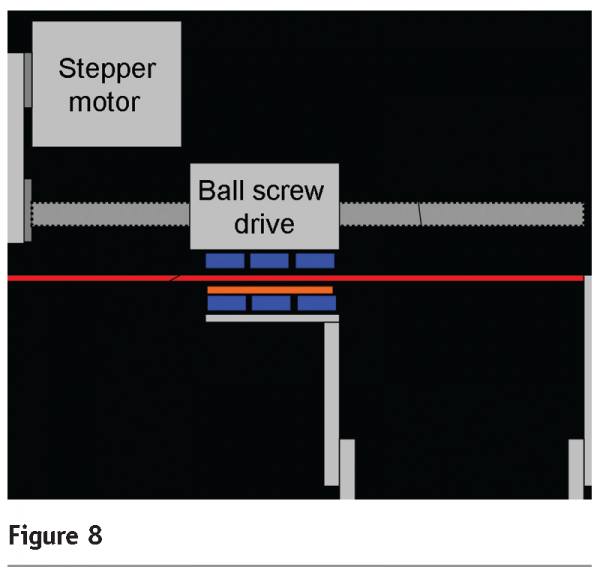

The actuator package used to move the jaws of the force gripper and the MR fluid gripper present a cleaning problem. To address the problem, a solution based on a linear magnetic coupling will be investigated. By using a linear magnetic coupling technique, all mechanical parts can be put into a sealed box (see Figure 8). The force is transferred to the jaws by the magnets and only the gripper jaws are exposed. The jaws can easily be disassembled and assembled without tools, allowing the gripper to be hosed down.

Gripper performance

So far in the project, only some rudimentary proof of principle tests have been performed on the first prototype grippers. However, the tests have been positive and the grippers have behaved as planned. The deformable Bernoulli gripper has been shown to lift both a round object (a small Granny Smith apple) and a flat one, and further objects will be tested in the future. The force gripper prototype has been tested by gripping a sponge model of a strawberry with different force settings and shows promising performance. Mounted in a table top rig, the MR fluid gripper has been shown to securely hold both bananas and apples.

Conclusion and further plans

Three novel gripper designs have been developed that all have interesting features suitable for food applications. They have the potential to handle a range of products and the results from initial trials are encouraging. Also, a complete robot work station suitable for gripper evaluation and hygienic evaluation of a food robot has been built. With this test platform and with the available resources in the NovelQ consortium, a rigorous study of robot station hygiene, gripper hygiene, gripper performance and robot station flexibility is possible.

The next stage of the project will be to make the grippers fully automated, allowing them to be mounted onto the robot. An extensive evaluation will be made of gripper lifting capacity, force exerted on the products and gripping speed measurements. The test platform will also allow tests using “real” gripping on a moving conveyor to measure achievable robot station cycle times. A microbial study will be performed to evaluate the grippers cross contaminating properties. Tests will also be made to see if an intermediate decontamination step of the gripper surface, dipping in boiling water or spraying with steam, can be used to reduce cross contamination.

In the later part of the project, the possibility of making a simplified PC user interface will be investigated. It is desirable that an operator should be able to “design” new ready meals without the need of extensive training. A graphical drag and drop system is proposed and will be further investigated.

Acknowledgment

This study has been carried out with financial support from the Commission of the European Communities, Framework 6, Priority 5 ‘Food Quality and Safety’ Integrated Project NovelQ FP6-CT-2006-015710.

More information

The project is an interdisciplinary collaboration between the Centre for Robotics and Automation – University of Salford and the food processing group – SIK AB Institute for Food and Biotechnology, in Gothenburg.

References

- www.novelq.org

- Jennergren L. (2004). Flexible Assembly of Ready-to-eat Meals, University library, ISBN: 91-7668-412-1, Örebro, Sweden

- Friedrich W. E., Lim P. K. (1997). Smart sensing enables robotic handling of variable objects, Industrial research limited, Auckland NZ.

- Chua P. Y., Ilschner T. and Caldwell D. (2003). Robotic manipulation of food products – a review. Industrial robot, vol. 30 no. 4.

- Connoly C. (2003). Gripping development at Silose. Industrial robot

- Stephan J. & Seliger G. (1999). Handling with ice – the cryo-gripper,a new approach. Assembly Automation, volume 19, Number 4, pp 332-337, MCB University Press, ISSN 0144-5154.

- Davis S., Gray J. O. and Caldwell D.G. (2008). An end effector based on the Bernoulli principle for handling sliced fruit and vegetables. Robotics and Computer- Integrated Manufacturing, vol 24, nr 2 April2008,p 249-257, ISSN:0736-5845

- A Binder, G Kroupa. (2003), Solid Stat Technology,pp. 64 – 68,October 2003.