Small NMR in food innovation

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 13 June 2008 | J. P. M. van Duynhoven, Gert-Jan W. Goudappel, Elena Trezza, Adrian M. Haiduc, Franck Duval, Wladyslaw P. Weglarz, Unilever Food and Health Research Institute, Vlaardingen, The Netherlands | No comments yet

NMR is a versatile tool for structural assessment of food materials and this pertains in particular for its benchtop and hand-held implementations. Such “small NMR” equipment can literally be deployed in all phases of foods innovation. This is illustrated by several industry examples.

NMR is a versatile tool for structural assessment of food materials and this pertains in particular for its benchtop and hand-held implementations. Such “small NMR” equipment can literally be deployed in all phases of foods innovation. This is illustrated by several industry examples.

NMR is a versatile tool for structural assessment of food materials and this pertains in particular for its benchtop and hand-held implementations. Such “small NMR” equipment can literally be deployed in all phases of foods innovation. This is illustrated by several industry examples.

Introduction

The food industry is under strong pressure from consumers and legislators to deliver products that promote sustainable wellbeing and health. Hence there is a strong drive to reduce high levels of fat, sugar and salt, since these are associated with adverse health effects. Since these ingredients critically determine taste and texture of the current generation of food products, the foods industry is now facing the challenge of re-designing their microstructures1.

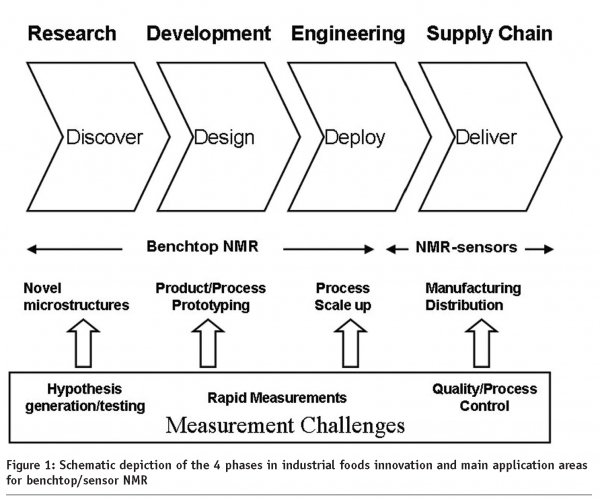

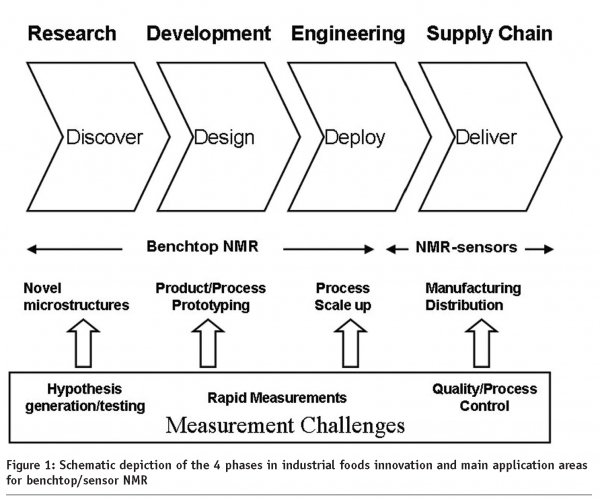

The competitive position of the food industry relies on the efficiency with which they can bring such innovations to the market. Within the innovation process one can roughly discern 4 phases1: Discover, Design, Deploy and Deliver (Figure 1). In the Discovery phase, new insights are acquired that allow the design of novel food products. In the Design phase, product developers transform these ideas into product prototypes. Subsequently, in the Deployment phase, food engineers scale up processes up to mass production. Another critical success factor is the efficiency of the supply chain, which Delivers food products to the consumer by safe manufacturing and efficient distribution, through a range of logistic channels. In all 4 phases, measurement technologies are critical for providing information that allows rational decision making. Within the realm of measurement technologies, NMR takes a unique position due to its wide range of applications in all 4 innovation phases2. The perception still exists; that NMR is a technique that requires expensive instrumentation, trained operators and data interpreters. However, relatively small, cheap, robust and easy-to-handle benchtop NMR instruments are available and can literally be operated at the workbench of food scientists and technologists alike. In recent years we have also witnessed the development of even more down-sized hand-held NMR “sensors”. Here, we will review the industrial opportunities of such “small NMR” equipment which will be illustrated from recent examples within our laboratory.

Phase-behaviour of foods

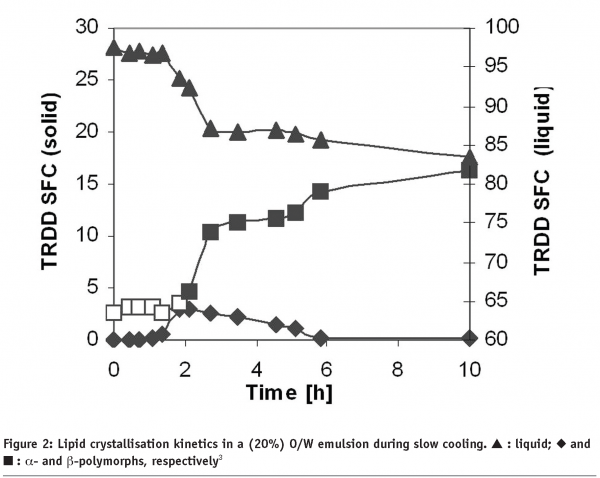

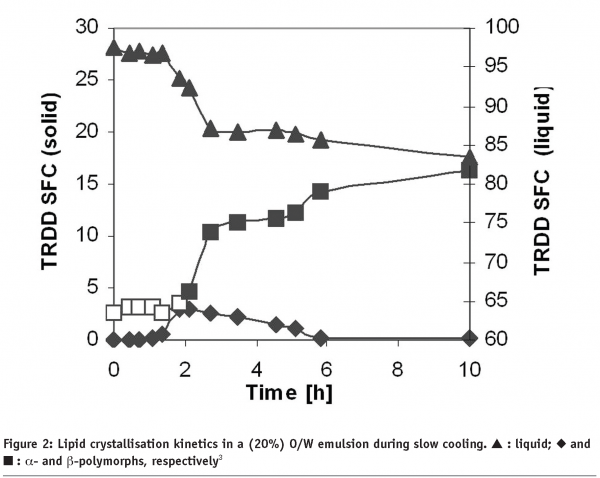

The different components in a food product can exist in different phases and this has a profound impact on sensory perception. Furthermore, depending on processing history, different phases may not exist in thermodynamic equilibrium as it could compromise stability. Typically, food scientists tend to describe food phase-behaviour in terms of crystal polymorphism, liquid and semi-solid states. Phase-behaviour of foods is typically assessed with XRD, DSC and microscopy, which are relatively high-end techniques that are only accessible in Discover and Design environments. An exception is the benchtop NMR measurement of Solid Fat Content in food lipids, which was introduced almost three decades ago. This NMR method uses rather crude signal acquisition and processing technology, but with modern commercial NMR hardware and software, much more structural detail can be obtained1. An example from the Deploy phase is shown in Figure 2, where lipid crystallisation was monitored within an oil-in-water emulsion that was produced at 60°C and subsequently cooled to 5°C in a storage tank. The amount of emulsified lipid in this emulsion was relatively modest (20%) but one can still resolve both a transient a-polymorph and monitor its conversion into a stable b-form. We validated this result against XRD, and found favourable compliance. The advantage of benchtop NMR over XRD is that it requires less capital investment, and is less demanding with respect to operation. The results in Figure 2 illustrate that this does not compromise on the amount of phase-compositional detail that can be obtained, even when this concerns relatively complex semi-formulated food products4.

Droplet sizing

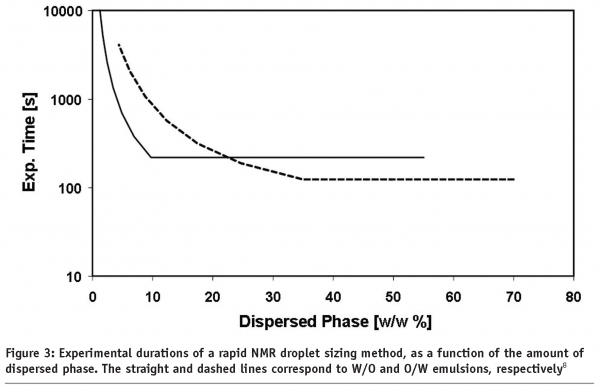

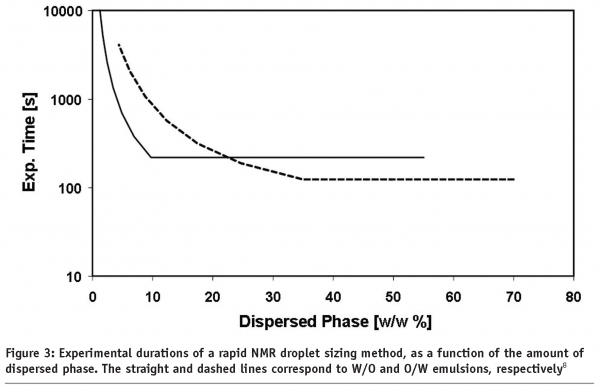

The droplet size distribution in food emulsions is an important parameter for predicting (storage) stability and rheology. For the measurement of droplet sizes, an arsenal of particle sizing techniques is available, but these suffer from drawbacks, such as high cost, the requirement of experienced staff and invasive and disturbing sample preparation. NMR does not have these disadvantages, and particular distinguishes itself by good precision, which is a prerequisite for use in Design and Deploy environments. We recently enhanced the throughput of the benchtop NMR droplet sizing method, without compromising precision and accuracy5. As one can observe in Figure 3, good measurement and time efficiency can be achieved, even at relatively low amounts of dispersed (droplet) phase.

Water (re)distribution

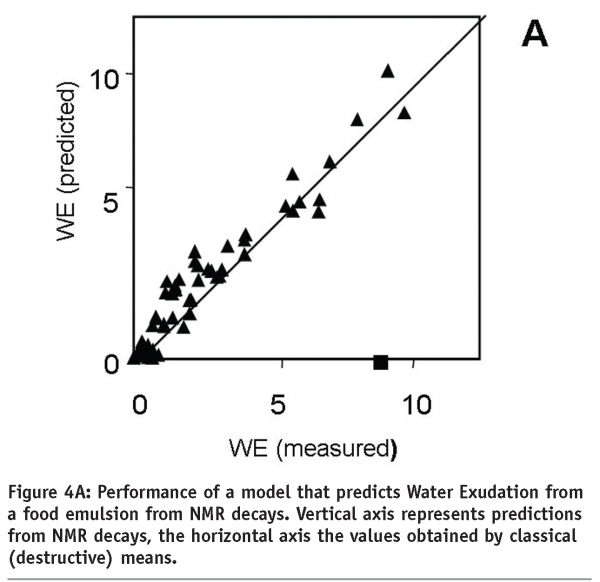

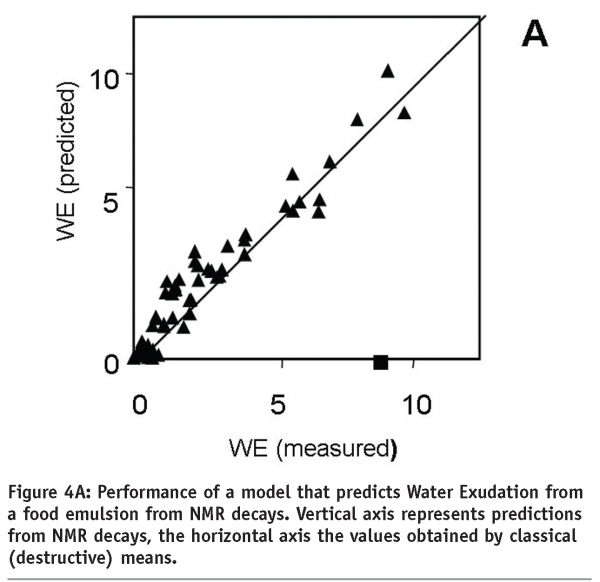

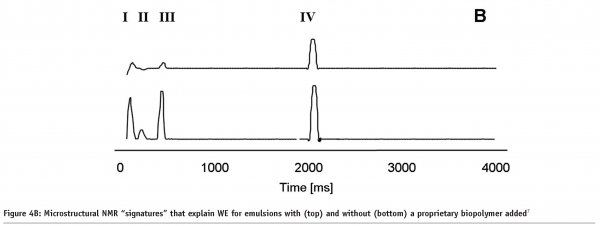

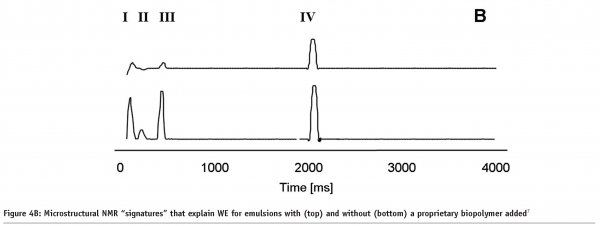

Water is a constituent of virtually every food product, and by its interaction with other components it exerts a critical role in determining texture. When food products are stored, structural rearrangements can take place, mostly induced by re-distribution of moisture. Due to its non-invasive/perturbing nature, NMR is in a unique position to establish the underlying structural events. We recently carried out studies on the relation between microstructure and Water Exudation (WE) during shelf-life of a water-continuous food emulsion. A range of these emulsions was prepared, and NMR relaxation decays were recorded which contain comprehensive microstructural information, and which can be mined by multi-variate analysis modelling2. Figure 4A shows the performance of a model that predicts Water Exudation from NMR decays. These models can also visualise those microstructural features that are responsible for Water Exudation, as represented in Figure 4B. The so-called T2 populations in these plots (very roughly speaking) correspond to water present in voids of different size2. One can observe that samples without biopolymer have a contribution of small voids, which is absent in samples with biopolymer. This explains the water retaining effect of this biopolymer in these emulsions.

Automation & miniaturisation

Within the Deploy phase there is a need for rapid feedback of microstructural information on product prototypes to developers and technologists. Here, the need to understand and control food structures is literally needed at the level of the laboratory bench or pilot plant. This challenge can ideally be addressed by easy-to-handle and cost-effective benchtop NMR systems. The robustness of benchtop NMR equipment makes them also quite amenable for automation. Figure 5 shows an automated set-up, operational in our laboratory, comprising a robot arm, a range of storage and tempering water baths, and three benchtop NMR spectrometers. Two spectrometers are dedicated to NMR relaxometric experiments, either conventional (such as Solid Fat Content) or of a more advanced nature6. The third spectrometer is dedicated to diffusometric measurements, such as droplet sizing in food emulsions3. In its current form this set-up is capable of handling up to 20,000 samples a year.

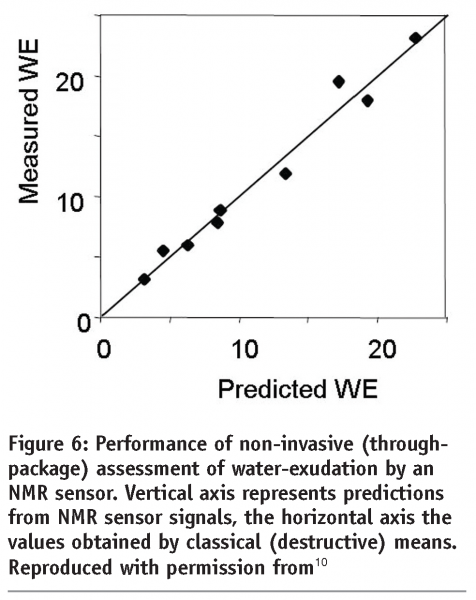

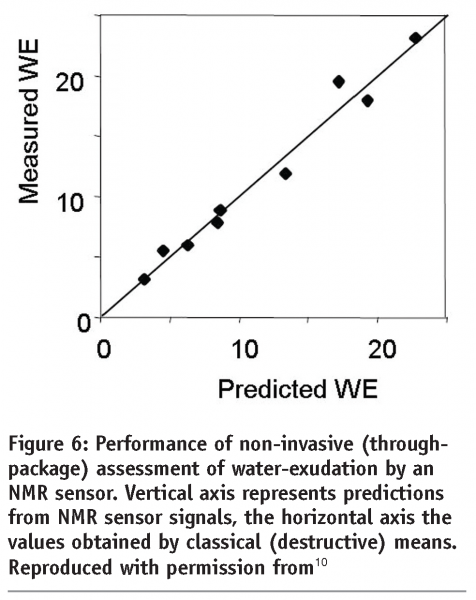

In the Deliver phase, there is a strong drive to move from the ‘classical’ process and quality control, typically taking place in an ‘off-line’ laboratory, to non-invasive, on-line and real-time measurements. Recently, NMR has also been presented in a truly non-invasive “sensor” mode, by deploying one-sided magnets with built-in measurement coils. In a recent study7, we investigated whether the microstructural quality of the aforementioned model emulsions, i.e. Water Exudation, could also be assessed by NMR sensors. By means of multi-variate methods, we were able to build models that could correlate signals obtained by these sensors to Water Exudation (Figure 6). Validation showed that indeed reliable ‘through-package’ inspection of Water Exudation was possible. This opens up opportunities for non-invasive and on-line testing of the microstructural quality of food products in manufacturing environments and in the supply chain.

Conclusion

In the Discovery phase, “Small NMR” can be exploited for explorative modelling of structure-property relations of foods. Within the Design/Deploy phases, implementation of relaxometric and diffusometric NMR methods on benchtop instrumentation has brought NMR to the workbench of the food technologists and product developers. We envisage that further miniaturisation of NMR instrumentation will take place within the next few years, thus moving NMR technology further into the Deploy and Deliver phase. The NMR sensor may be a first example of how hardware developments enable truly online sensing of meso- and micro-structural product quality11.

Acknowledgement

Part of this work was supported by the European Union, by Marie Curie grants HPMI-CT-2002-167 (ET, AH, “BENCHNMR”), HPMI-CT-2001-00154 (FD, “NEW FAT PROCESSING”) and MEIF-CT-2005-009475 (WW, “WATERMAP”).

References

- Product/process integration in food manufacture: Engineering sustained health, Norton I, Fryer P, Moore S, Aiche Journal 2006, 52 (5), 1632-1640.

- NMR in Foods – The Industrial Perspective (2007), van Duynhoven JPM, Haiduc AM, van Dorsten, F, van Velzen E, Magnetic Resonance in Food Science – From Molecules to Man, RSC Books, London.

- Comprehensive Phase-Compositional Analysis of Lipid Based Food Products (2005), Trezza, E., Haiduc, A., van Duynhoven, J.P.M, Magnetic Resonance in Food Science, Eds. RSC Books, London.

- Practical Implications of the Phase-Compositional Assessment of Lipid Based Food Products by Time-Domain NMR, Duval F, van Duynhoven JPM, Bot A, JAOCS 2006, 83(11), 905-912.

- A rapid benchtop NMR method for determination of droplet size distributions in food emulsions, van Duynhoven JPM., Maillet B, Schell J, Tronquet M, Goudappel GJW, Trezza E., Bulbarello A, van Dusschoten, D, Eur. J. Lip. Sci. Techn, 2007 109-113.

- Correlation of porous and functional properties of food materials by NMR relaxometry and multivariate analysis. Haiduc AM, van Duynhoven, JPM, Magn. Res. Im. 2005, 23 (2), 343-345.

- Multivariate modelling of the microstructural quality of food emulsions based on NMR, Haiduc AM, van Duynhoven JPM, Heussen P, Reszka AA, Reiffers-Magnani C, Food Res. Int. 2007, 40 (4): 425-434 2007

- Rapid Phase compositional assessment of lipid based food products by TDNMR, Trezza E, Haiduc AM, Goudappel GJW, van Duynhoven JPM, Magn. Reson. Chem. 2006, 44(11) 1023-1030.

- Scope of droplet size measurements in food emulsions by pulsed field gradient NMR at low field. van Duynhoven JPM, Goudappel GJW, van Dalen G, van Bruggen, PC, Blonk JCG, Eijkelenboom APAM. Magn. Res. Chem. 2002, 40, S51-S59.

- Non-invasive ‘through-package’ assessment of the microstructural quality of a model food emulsion by the NMR MOUSE, Haiduc AM, Trezza E, van Dusschoten D, Reszka AA, van Duynhoven JPM, Lebenm. Wiss. Techn. 2007, 40(4) 737-743.

- Motional relativity and industrial NMR sensors, Hills BP, Wright KM, J. Magn. Reson. 2006, 178 (2), 193-205.