The risks of psychrotrophic Clostridium botulinum in MAP and vacuum packed chilled foods

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 18 August 2008 | Greg Jones, Senior Research Officer for the Preservation, Processing and Spoilage Group, Campden & Chorleywood Food Research Association | No comments yet

Foodborne botulism is a severe illness that is caused by the consumption of foods containing a neurotoxin produced by a bacterium called Clostridium botulinum. Very little of this toxin is required to cause illness; for example, in 2002, a 35 year old man put a piece of baked potato in his mouth and then spat it out again as it tasted bad. He ingested enough toxin to put him in hospital for six and a half months4.

Foodborne botulism is a severe illness that is caused by the consumption of foods containing a neurotoxin produced by a bacterium called Clostridium botulinum. Very little of this toxin is required to cause illness; for example, in 2002, a 35 year old man put a piece of baked potato in his mouth and then spat it out again as it tasted bad. He ingested enough toxin to put him in hospital for six and a half months4.

Foodborne botulism is a severe illness that is caused by the consumption of foods containing a neurotoxin produced by a bacterium called Clostridium botulinum. Very little of this toxin is required to cause illness; for example, in 2002, a 35 year old man put a piece of baked potato in his mouth and then spat it out again as it tasted bad. He ingested enough toxin to put him in hospital for six and a half months4.

The physiology of C. botulinum means it favours growth in environments lacking in oxygen. Foods packaged in cans, vacuum packs and modified atmosphere packs are of particular concern, although aerobically packed foods may also support the growth of this organism if the oxygen tension is lower than atmospheric levels. Foods at potential risk from C. botulinum need to meet specific criteria to control this organism or should have their safety assessed as described below.

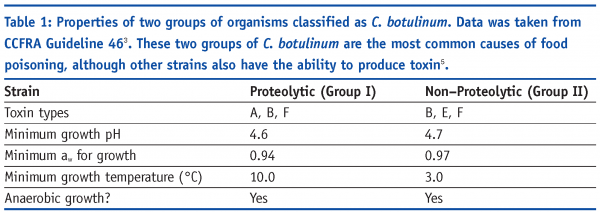

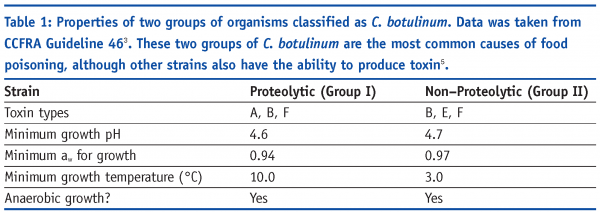

C. botulinum is a spore forming organism and consists of several different types (see Table 1), each of which has different survival and growth characteristics. From a food processing point of view, the different types can be considered more simply as two different groups: mesophilic or psychrotrophic.

The mesophilic strains of C. botulinum produce particularly heat resistant spores and a minimum heat treatment of 121°C for three minutes (F03) is recommended for ambient stable products in order to reduce the level of risk for this organism in such products. This is the basis of the industry accepted minimum canning process that has been in use for many years.

Of more interest recently are the psychrotrophic strains of C. botulinum which pose a particular risk to chilled products, as these strains have the ability to grow at temperatures as low as 3°C7.

This is of particular relevance because the market for chilled foods has increased from GBP 4.6 billion in 1999 to GBP 7.4 billion in 2005 with no signs of that growth slowing (www.chilledfood.org). Chilling can help increase the shelf life of products, and further extension of shelf life can be achieved through modified atmosphere and vacuum packaging, although there are strict guidelines on the shelf-life that can be assigned to chilled products based on the processing and formulation characteristics of the food.

The ten day rule

In the early 1990’s, the Advisory Committee for the Microbiological Safety of Foods (ACMSF) reviewed all the data available on the growth of psychrotrophic C. botulinum with a view to introducing a set of guidelines that, if followed correctly, would allow the safe production of chilled foods2. These guidelines were published in 1992 and they contain a list of intrinsic properties which, if at least one is met, will extend the shelf life of a chilled MAP / VP / low oxygen food to beyond 10 days. Since then CCFRA has published a more user – friendly document3, and the FSA have recently published an updated set of guidelines1. All these more recent documents adhere to the same set of factors listed here. Should none of the factors be met, the shelf life is limited to below 10 days and further testing is required for the product to be accepted as safe. The factors mentioned in all the guidelines are as follows:

- pH of 5 or less throughout the product

- Water activity of 0.97 or less throughout the product

- A salt level of 3.5 per cent or more throughout the product

- A heat treatment of 90°C for 10 minutes or equivalent

- Any combination of preservative factors and / or heat which has been shown consistently to prevent growth and toxin production by psychrotrophic C. botulinum

These guidelines have proven to be extremely successful at preventing outbreaks of botulism in the UK. Only one case that could be linked to the food industry has been reported since 1992, linked to the consumption of hummus in 2004. The other five reported cases since 1992 were associated with either foreign travel or home preserved products imported in to the UK (www.hpa.org.uk). It is worth emphasising that, of these six cases, two resulted in death.

“My product doesn’t meet any of the above guidelines, but I want a chilled shelf life of longer than 10 days”

This is a commonly heard comment which deserves to be addressed. The ACMSF guidelines, whilst effective, are quite restrictive with regards saleable products in today’s sophisticated market. For example, a MAP fresh pasta product would not meet the ACMSF guidelines; however, these products can have a shelf life of three weeks or more. This is possible by proving that the product does not support the growth of C. botulinum over shelf life (as per the fifth point of the guidelines above), and often takes the form of a challenge test. A challenge test is based on deliberate introduction of pathogenic microorganisms into a product, followed by regular sampling over the proposed shelf life to monitor their growth (CCFRA Technical Manual No. 2011). The products are stored using the upper limits of the proposed storage temperature, and thus the test represents a worst-case scenario. In the case of our hypothetical fresh pasta product, should there be no growth or toxin production from introduced non-proteolytic C. botulinum over a 21 day chilled shelf life, then it can be deemed safe with respect to that organism over that shelf life.

“What about preservatives other than salt?”

Three point five per cent salt (w/w NaCl) would impart a distinctive salty flavour to most products which may not be found acceptable by the consumer. This is compounded by the recent drive to reduce salt in processed foods by the UK government (http://www.salt.gov.uk/). As reducing the amount of salt in a food will increase its water activity, other preservative systems can be used to suppress C. botulinum. There is evidence to support the use of preservatives as anti–botulinal agents; however, each individual combination of preservative, processing and product formulation will be unique in its ability to support or suppress the growth of C. botulinum. Nisin, for example, is added to cheese products to suppress the growth of clostridia6; however, there have been studies that show nisin to be ineffective with regards suppression of C. botulinum in meat products8,9. Cured meat products use nitrite salts as curing agents, and these impart the pink colour that we associate with cured meats. There is much evidence to support the use of nitrite as an anti–botulinal agent; however, this does not seem to be the case in every situation. Indeed the addition of nitrite to one low pH system increased clostridial growth12, although the vast majority of published studies have shown that a combination of low pH and nitrite has an inhibitory effect10.

“How can I make my added preservative more effective at suppressing C. botulinum?”

The answer to this question depends on the preservative that is being used. As alluded to in the previous section, lowering the pH of a product can have an effect on the anti–bacterial action of a given amount of preservative. For weak acid based preservatives, lowering pH can have an effect on the anti–botulinal efficacy of preservatives. In essence, the lower the pH of a product containing weak acid preservatives, the more undissociated acid will be present. It is the undissociated acid which has an antimicrobial effect, therefore a synergistic combination of low pH and abundance of undissociated weak acid preservative will cause more inhibition. For weak acid based preservatives, there is much less evidence for their anti–botulinal activity than for nitrite based preservatives, although what there is indicates that C. botulinum is sensitive to these compounds10.

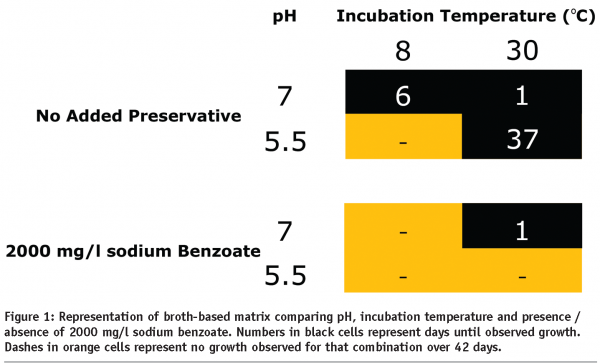

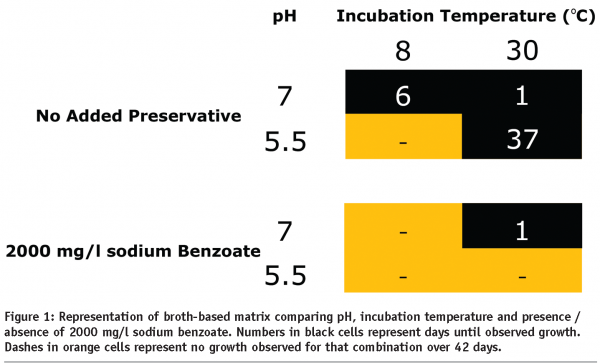

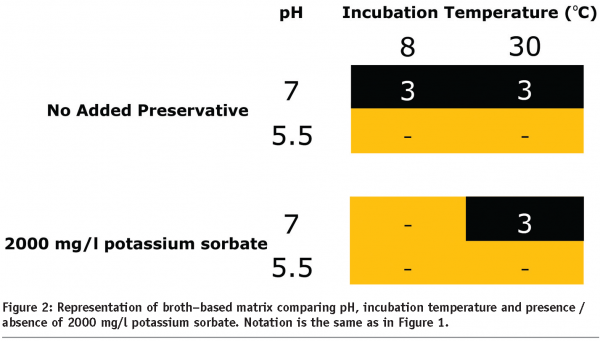

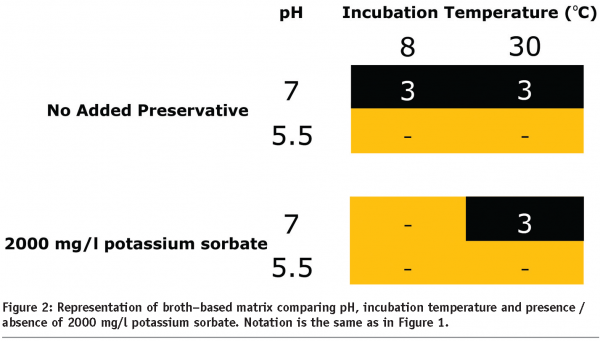

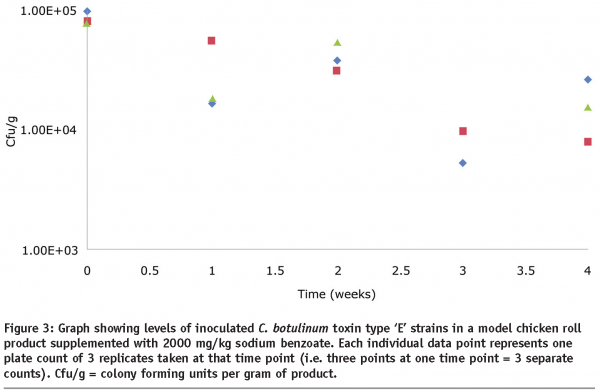

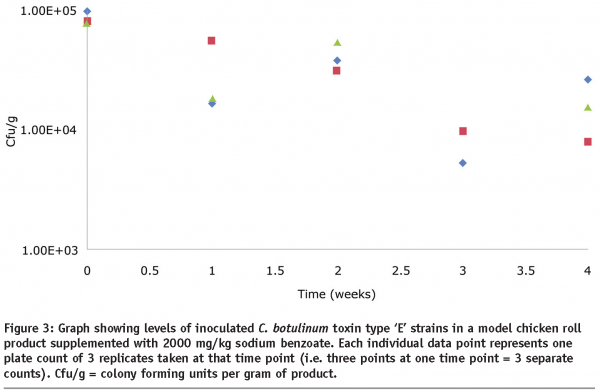

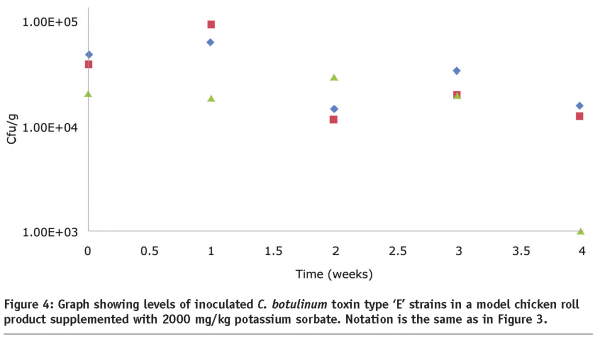

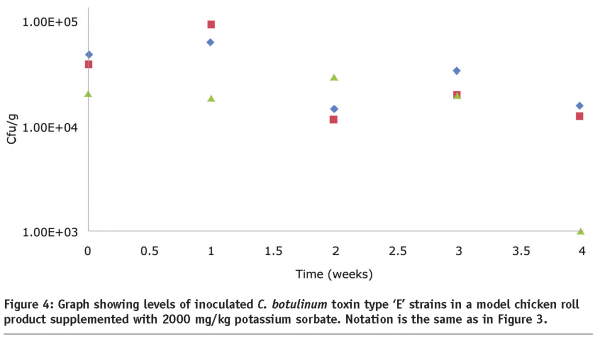

CCFRA is currently involved in a three year research project funded by its membership which aims to add to the evidence for preservative factors being able to inhibit the growth of non–proteolytic C. botulinum at chill temperatures. Five strains of the organism were used, and the response to a combination of low pH and preservatives such as potassium sorbate and sodium benzoate was striking. In a broth–based system, lowering the pH from 7.0 to 5.5 in combination with 2000 mg/l potassium sorbate or sodium benzoate resulted in no growth being observed over a 42 day chilled shelf life (Figures 1 and 2). In a C. botulinum challenge test of a vacuum packed chicken roll product produced on–site at CCFRA, potassium sorbate and sodium benzoate supplemented products showed no detectable growth of C. botulinum over 42 days storage at 8°C (Figures 3 and 4).

Conclusions

Prevention of food poisoning from psychrotrophic C. botulinum in the UK currently relies on following the guidelines produced in 1992 by the ACMSF. The current market for high quality ‘fresh’ products has resulted in the widespread adoption of MAP / VP as methods of extending shelf life. However, as these products are minimally processed with low salt levels, there is a risk of growth and toxin formation. Therefore, if a chilled shelf life of greater than 10 days is desired, it is vitally important that the product be proven safe. Challenge testing with C. botulinum is an effective method of ascertaining the growth–supporting properties of a product. The addition of preservatives is a popular method of inhibiting the growth of C. botulinum and there is evidence that weak acid preservatives in conjunction with a lowered pH are effective. The project at CCFRA aims to add to the evidence for the anti–botulinal properties of preservatives in chilled foods, which will provide more options to manufacturers during product development and help attain the objective of final formulations achieving the desired extended shelf life.

References

- Food Standards Agency. 2008. Guidance on the safety and shelf life of vacuum and modified atmosphere packed chilled foods. http://www.food.gov.uk/foodindustry/guidancenotes/foodguid/vpguide

- Advisory Committee on the Microbiological Safety of Food. Report on Vacuum Packaging and Associated Processes. 1992.

- Betts, G. D. Code of practice for the manufacture of vacuum and modified atmosphere packaged chilled foods with particular regard to the risk of botulism. 1996. CCFRA.

- Bhutani, M., E. Ralph, and M. D. Sharpe. 2005. Acute paralysis following “a bad potato”: a case of botulism. Can. J. Anaesth. 52:433-436.

- Collins, M. D. and A. K. East. 1998. Phylogeny and taxonomy of the food-borne pathogen Clostridium botulinum and its neurotoxins. J. Appl. Microbiol. 84:5-17.

- Erich Luck and Martin Jaeger. 1997. Antimicrobial Food Additives: Characteristics, Uses, Effects.

- Graham, A. F., D. R. Mason, F. J. Maxwell, and M. W. Peck. 1997. Effect of pH and NaCl on growth from spores of non-proteolytic Clostridium botulinum at chill temperature. Lett. Appl. Microbiol. 24:95-100.

- Lindstrom, M., M. Mokkila, E. Skytta, E. Hyytia-Trees, L. Lahteenmaki, S. Hielm, R. Ahvenainen, and H. Korkeala. 2001. Inhibition of growth of nonproteolytic Clostridium botulinum type B in sous vide cooked meat products is achieved by using thermal processing but not nisin. J. Food Prot. 64:838-844.

- Mazzotta, A. S., A. D. Crandall, and T. J. Montville. 1997. Nisin Resistance in Clostridium botulinum Spores and Vegetative Cells. Appl. Environ. Microbiol. 63:2654-2659.

- Davidson, P.M, Sofos, J.N, and Branen, A.L.. 2005. Antimicrobials in Food. CRC Press.

- Rose S.A. and Stringer M.F. Guidelines for microbiological challenge testing. 1987. CCFRA.

- Shank, J. L., Silliker, J. H., and Harper, R.H. 1962. The effect of nitric oxide on bacteria. Appl. Microbiol. 10:185-189.

Issue

Related topics

Packaging & Labelling, Quality analysis & quality control (QA/QC)