Packaging materials and methods for dairy applications

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 18 August 2016 | Professor Kata Galić, Faculty of Food Technology and Biotechnology, University of Zagreb | 2 comments

Professor Kata Galić, Faculty of Food Technology and Biotechnology, University of Zagreb, looks further into the development and introduction of plastic materials, both alone and in combination with paper…

Milk is the best example of a food product that, due to processing technology, packaging material and method, is able to extend its shelf life from hours into weeks and months.

The first packaging of milk came with the introduction of sterilised milk processing, in which the glass bottle formed an integral part. The glass bottle as the retail package for milk was used until the 1930s, at which time waxed paper was introduced. The development and introduction of plastic materials, both alone and in combination with paper, resulted in a wide range of containers suitable for dairy products packaging.

The shelf-life of bottled fluid milk is reported to average between 10 and 21 days when stored at 4-8°C1. The shelf life varies depending on raw milk quality, processing conditions, microbial growth, packaging materials2, exposure to light2, 3 and temperature abuse4.

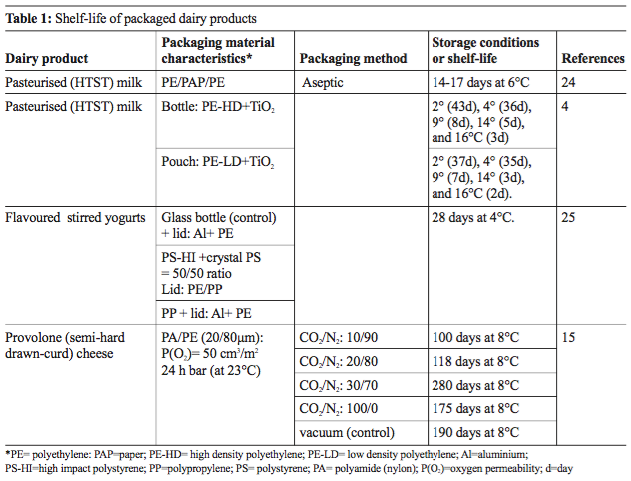

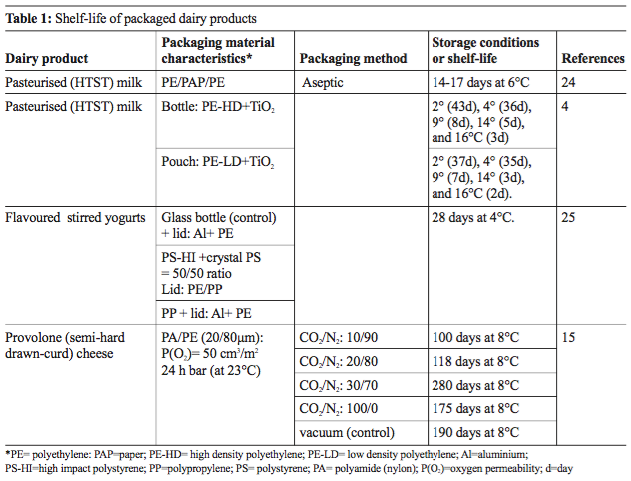

The dairy industry is able to achieve a 45-day shelf life through the use of ultrapasteurisation (UP) processes, while ultra-high temperature (UHT) processed products achieve a shelf life of three months to one year with no refrigeration5. The shelf life study, by Petrus et al.4 evaluated the influence of storage temperature on the microbiological stability of homogenised whole pasteurised milk packaged in different polyethylene (PE) monolayer materials, pigmented with titanium dioxide (TiO2). Based on the results of the study, high-density polyethylene (PE-HD) bottles were better for storing pasteurised milk compared with that of a low-density polyethylene (PE-LD) pouch (Table 1, see below).

Zygoura et al.6 evaluated the influence of the packaging material on the shelf life of commercialised pasteurised milk in Greece. The product was stored at 4°C with exposure to fluorescent lighting. Under these conditions the stability was only five days. Although the product had been exposed to light, the researchers had used multi-layered plastic bottles with a high barrier. Polyethylene terephthalate (PET) is another plastic material used for milk packaging. Pigmented PET enhances its versatility by protecting the food from light, which in turn helps to protect food flavour against light-induced lipid oxidation5, 7.

Losses of ascorbic acid (AA) during milk storage have been reported for UHT milk storage at various temperatures; durations of storage; and with different packaging materials, such as C-enamelled tinplate cans8; brown glass bottles9; and aseptic multilayer containers5. Jeon et al.8 reported a total loss of AA in UHT milk packed in C-enamelled tinplate cans after 30 days of storage at 3°C. According to Solano-Lopez et al.10 AA concentration degraded in the UP-PET bottled milk after 60 days of refrigerated storage, while sensory evaluation of the milk remained without noticeable change.

The most popular material in current use for fresh yogurt is thermoformed TiO2 pigmented high impact polystyrene (PS-HI), with either an aluminium foil/plastic laminate or a paper/plastic laminate heat-seal lid or closure. For pasteurised, spoonable yogurt products, barrier laminated materials are desirable if a long shelf-life is needed, with some having shelf lives of 4–6 months at ambient temperatures. For these products, a low water vapour transmission rate (WVTR) is required to prevent the product from losing water during shelf life. A good O2 barrier packaging will help to protect the product from oxidation, and a good light barrier will help to delay fading of light-sensitive colours and avoid light-induced oxidation.

Drinking-yogurt products are packaged in PE-HD bottles sealed with either aluminium foil laminate heat-seal closures, or with PE-LD caps. Bottles made from other plastics (e.g. PET) may also be used. For long-life, heat-treated drinking-yogurt products, composite materials made with: plastic/Alu-foil/paperboard with good water vapour, O2, and light barrier properties are also often used. Opaque or semi-opaque packaging materials, most usually containing a white pigment such as TiO2, are normally used for yogurt11.

Different types of packaging concepts are also required for various types of cheeses. Permeability to O2, CO2, and water vapour transmission rates for packaging films are among the most essential factors in determining the package atmosphere composition, which may influence the product’s deterioration rate12. Cottage cheese has a shelf life of 21 to 28 days, although there is often considerable loss of quality during this period13.

Modified atmosphere packaging (MAP) can be applied to dairy products to control some of the associated fungal problems and extend their shelf life. The applied gas compositions for packaging of dairy products can vary from 10% to 100% CO2, balanced with N2 as an inert filler gas, preventing package collapse as a result of CO2 solubilisation in the cheese product.

Subsequently, the CO2 is able to interchange dynamically between the product and the headspace gas. The degree of this exchange is expected to depend on material properties, CO2 solubility in the specific cheese, as well as on the product to headspace volume ratio and the initial concentration of CO2 in both the packaging gas and product. During transportation and storage, the CO2 will continue to exchange as a response on changes in temperature conditions14. A low level of CO2 in MAP application could significantly improve the shelf life of some cheeses. Favati et al.15 evaluated the shelf-life of portioned Provolone cheese packaged in a protective atmosphere using different CO2/N2 gas mixtures at 4°C and 8°C, in order to simulate, respectively, the most common domestic and retail storage conditions. Control samples were vacuum-packaged. Furthermore, the acquired data was utilised to predict the commercial shelf life of the cheese. The gas mixture made up of 30% CO2 and 70% N2 guaranteed portioned Provolone cheese shelf life of 280 days (Table 1).

Active packaging is one of the innovative food packaging systems to have been introduced to the market. Major active packaging techniques include substances that absorb moisture, oxygen, carbon dioxide, ethylene, flavours and odours or release carbon dioxide, antimicrobial agents, antioxidants and flavours. Several applications of active packaging systems that have been commercialised include oxygen-scavenging, carbon dioxide-absorbing, moisture-scavenging (desiccation) and antimicrobial systems16.

Demands for longer shelf life and wider distribution of dairy products have resulted in the development of processes and packaging concepts that increase the shelf life of these products in cold chain distribution17.

Use of a non-thermal food preservation technology, such as pulsed electric fields (PEF) and high-pressure technology (HPP), may represent a viable alternative to produce an extended shelf life (ESL) pasteurised product, or to apply a second preservation treatment to thermally pasteurised milk without further altering its sensory and nutritional attributes18, 19. Studies by Sepulveda et al.19 have shown that the application of PEF immediately after HTST pasteurisation extended the milk’s shelf life to 60 days, while PEF-processing after eight days caused a shelf life extension of 78 days. The study of Evrendilek

The study of Evrendilek et al.20 showed that PEF and PEF+heat treatments were particularly effective in increasing the shelf life of chocolate milk. Chocolate milk was packaged in tri-laminate plastic containers. Container lids were made from a combination of polyamide (PA), aluminium foil, PE-LD and the cups from a combination of high impact polystyrene (PS-HI), polyvinylidene chloride (PVDC), and PE-LD.

However, it is important to study not only the effects of these techniques on the inactivation of micro-organisms, but also the influence on the food product itself and processing conditions on the packaging material. The reason for this is that, in many of the new applications, the products will be processed in their packaging21-23.

About the author

Kata Galić is professor at the University of Zagreb, Faculty of Food Technology and Biotechnology (PBF). She graduated in 1982, received her M.Sc. in 1985 and Ph.D. degree in 1989, from the PBF, University of Zagreb. She is executive committee member of the European Federation of Food Science and Technology (EFFoST) and Croatian Society of Food Technologists Biotechnologists and Nutritionists (CROFoST). She is also a member of the Royal Society of Chemistry (UK) and marketing task force member of the International Union of Food Science and Technology (IUFoST). Her research interest includes permeability characterisation of polymeric materials and factors affecting barrier changes of polymers aimed for food packaging. This also includes shelf life determination of packaged food.

References

- 1. Petrus R.R., Freire M.T., Setogute L., Higajo V.M. (2011) Effect of pasteurization temperature and aseptic filling on the shelf-life of milk, Alim. Nutr. Araraquara, 22 (4) 531-538

- Cladman W., Scheffer S., Goodrich N., M.W. Grffiths (1998) Shelf-life of Milk Packaged in Plastic Containers With and Without Treatment to Reduce Light Transmission, Int. Dairy Journal 8 (1998) 629-636

- Simon M., Hansen A.P. (2001) Effect of various dairy packaging materials on the shelf life and flavor of ultrapasteurized milk. J. Dairy Sci. 84:784–791

- Petrus R.R., Loiola C.G., Oliveira A.F. (2010) Microbiological Shelf Life of Pasteurized Milk in Bottle and Pouch, J. Food Sci. 75 (1) M36-M40

- Kontominas M.G. (2010) Packaging and the Shelf Life of Milk. In: Food packaging and shelf life: a practical guide (edited by Gordon L. Robertson). Taylor and Francis Group, LLC

- Zygoura P., Moyssiadi T., Badeka A., Kondyli E., Savvaidis I., Kontominas M.G.E. (2004) Shelf life of whole pasteurized milk in Greece: effect of packaging material. Food Chem. 87:1–9

- Van Aardt M., Duncan S.E., Marcy J.E., Long T.E., Hackney C.R. (2001) Effectiveness of Poly(ethylene terephthalate) and High-Density Polyethylene in Protection of Milk flavor, J.Dairy Sci., 84:1341-1347

- Jeon I.J., Thomas E.L., Reineccius G.A. (1978) Production of volatile flavor compounds in ultrahigh-temperature-processed milk during aseptic storage. J. Agric. Food Chem. 26:1183–8

- Fink R., Kessler H.G. (1986) Reaction kinetics evaluation of the oxidative changes in stored UHT milk. Milchwissenschaft 41:90–94

- Solano-Lopez C.E., Ji T., Alvarez V.B. (2005) Volatile Compounds and Chemical Changes in Ultrapasteurized Milk Packaged in Polyethylene Terephthalate Containers, J. Food Sci., 70 (6) C407-C412

- MacBean R.D. (2010) Packaging and the Shelf Life of Yogurt. In: Food packaging and shelf life: a practical guide (edited by Gordon L. Robertson). Taylor and Francis Group, LLC

- Poças F.M., Pintado M. (2010) Packaging and the Shelf Life of Cheese. In: Food packaging and shelf life: a practical guide (edited by Gordon L. Robertson). Taylor and Francis Group, LLC

- Hotchkiss J.H., Werner B.G., Lee E.Y.C. (2006) Addition of Carbon Dioxide to Dairy Products to Improve Quality: A Comprehensive Review, Comprehensive Reviews in Food Science and Food Safety, 5: 158-168

- Singh P., Wani A.A., Karim A.A., Langowski H-C. (2012) The use of carbon dioxide in the processing and packaging of milk and dairy products: A review, Int. J. Dairy Tech. 65 (2) 161-177

- Favati F., Galgano F., Pace A.M. (2007) Shelf-life evaluation of portioned Provolone cheese packaged in protective atmosphere, LWT 40: 480–488

- Jalilzadeh A., Tunçtürk Y., Hesari J. (2015) Extension Shelf Life of Cheese: A Review, Int. J. Dairy Sci. 10 (2): 44-60

- Rysstad G., Kolstad J. (2006) Extended shelf life milk—advances in technology, Int. J. Dairy Tech. 59 (2) 85-96

- Abida, J., Rayees, B., Masoodi, F. A. (2014) Pulsed light technology: a novel method for food preservation, Int. Food Res. J., 21 (3): 839-848

- Sepulveda D.R., Góngora-Nieto M.M., Guerrero J.A., Barbosa-Cánovas G.V. (2005) Production of extended-shelf life milk by processing pasteurized milk with pulsed electric fields, J. Food Eng. 67: 81–86

- Evrendilek G.A., Dantzer W.R., Streaker C.B., Ratanatriwong P., Zhang Q.H. (2001) Shelf-life evaluations of liquid food treated by pilot plant pulsed electric fielf system, Journal of Food Processing and Preservation 25: 283-297

- Caner, C., Hernandez, R.J., Pascall, M., Balasubramaniam,V.M., Harte, B.R. (2004) The effect of high-pressure food processing on the sorption behaviour of selected packaging materials. Packaging Technology and Science, 17(3):139–153

- Berg L., Jongbloed H., van Boxtel L., (2006) Impact of mild preservation techniques on packaging. New Food 2 (23) 1-9

- Chavan R.S., Chavan S.R., Khedkar C.D., Jana A.H. (2011) UHT Milk Processing and Effect of Plasmin Activity on Shelf Life: A Review, Comprehensive Reviews in Food Science and Food Safety, 10: 251-268

- Fromm H.I., Boor K.J. (2004) Characterization of Pasteurized Fluid Milk Shelf-life Attributes, J. Food Sci., 69 (8) M207-M214

- Sanint-Eve A., Lévy C., Le Moigne M., Ducruet V., Souchon I. (2008) Quality changes in yogurt during storage in different packaging materials, Food Chem. 110: 285–293

Thank you for sharing your great information. I read your blog daily . It give me so much knowledge and ideas.

Manufacturers love making new products for us to use, but then we pay the expense of disposing of them. For instance why do we need hybrid packaging such as plastic/aluminium foil/cardboard containers, with a screw on polythene lid, a favourite for alternative type milks.They could alternatively be packaged in the standard waxed or polythene film lined cardboard used for milk. The former is very difficult to recycle, and mostly ends up on the tip face, while the latter standard milk carton is completely recyclable .We also seem to have to many plastic types in food packaging, PVC,PCDC and polystyrene could be eliminated. Sorting of the remaining plastics , PET; high and low density polythene, and polypropylene, for recycling now becomes easier if they are only used as transparent, translucent and opaque respectively. A cleaner and simpler plastic waste stream makes all the recoverables more valuable.