New teardrop tube magnet from Bunting

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 1 March 2017 | Bunting Magnetics | 1 comment

Bunting has developed a new design of Rare Earth Tube Magnet for use in removing fine iron from dry powders…

Bunting has developed a new design of Rare Earth Tube Magnet for use in removing fine iron from dry powders. The Teardrop Tube Magnet retains the high surface magnetic field of 12,000 gauss, but the shape prevents fine powder from building up on the surface.

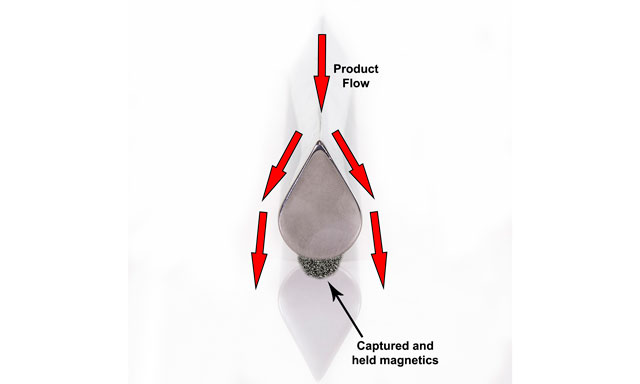

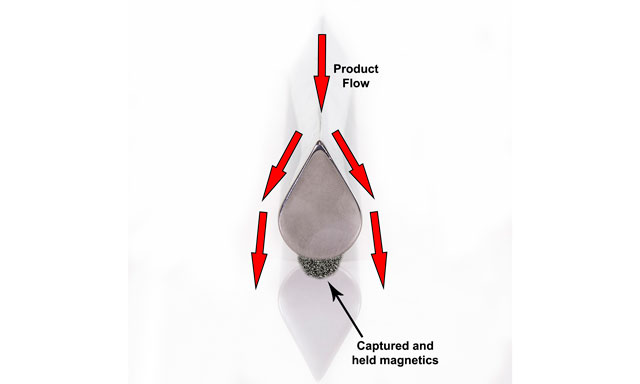

Figure 1 – The Bunting Teardrop Tube Magnet

Bunting Magnetics is one of the world’s leading suppliers of Magnetic Separators and Metal Detectors. The European manufacturing headquarters are based in Berkhamsted in Hertfordshire, UK and they have an extensive overseas network of distributors and marketing agents. In January, the company acquired Master Magnets, significantly expanding their range of Magnetic Separators and Metal Detectors.

Tube Magnets are used extensively in the processing industry to capture magnetic susceptible foreign bodies, including screws, nuts, bolts, and small iron shards, in both dry and wet applications. Metal Contamination causes damage to delicate processing equipment, as well as affecting the end-quality and purity of the product. Tube Magnets are commonly used in the form of a Grate Magnet, where several Tubes form a Magnetic Separation grid.

Rare Earth Magnets are constructed out of Neodymium Iron Boron magnet slugs. These produce the highest permanent magnetic field and are used to separate very fine iron and weakly magnetic stainless steel from solids and liquids.

Even though the Rare Earth Tube Magnet is a sphere, fine non-magnetic material often builds up on the upper-most point of the Tube. Over time this ‘bridging’ can increase and ultimately cause a blockage. The build-up always reduces the separation performance, increasing the likelihood of metal contamination continuing through the process.

The new Teardrop Magnet has the point of the tear orientated into the product flow. The surface area on the point of the tear is very small and prevents fine powder collecting on the surface. The powder then flows under gravity over the side of the Tube Magnet, with any magnetically susceptible materials attracted to the high magnetic force. These magnetics migrate to the bottom of the Tube Magnet, where they are securely held away from the product flow.

Figure 2 – Product flow around the Bunting Teardrop Tube Magnet

The new Teardrop Tube Magnet is available as a single Tube or as part of a multi-Tube Grate Magnet assembly.

For further information on the Teardrop Tube Magnet, please contact us on [email protected]

This looks like a great design. Cheers to Bunting for producing and innovating new products in this industry. Magnetic separators should continue to be an industry where R&D and time are being put into it, as it is of utmost importance to our society.