Peristaltic pump serves up tasty benefits for the food industry

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 11 November 2009 | Watson-Marlow Pumps Group | No comments yet

St Helens-based Lea Green Foods is using innovative peristaltic pump technology from the Watson-Marlow Pumps Group to dose oil into vegetable trays with both precision and cleanliness.

St Helens-based Lea Green Foods is using innovative peristaltic pump technology from the Watson-Marlow Pumps Group to dose oil into vegetable trays with both precision and cleanliness.

St Helens-based Lea Green Foods is using innovative peristaltic pump technology from the Watson-Marlow Pumps Group to dose oil into vegetable trays with both precision and cleanliness.

Lea Green Foods was founded in 1997 with the objective of providing a range of pastes and purees to the food service and manufacturing markets. In just 12 years the site at St Helens has grown to 9,000 sq ft and is home to 14 employees.

Last year the company wanted to introduce a new process that entailed repeatable, accurate and hygienic dosing of vegetable oil into trays of produce such as tomatoes and roasted peppers.

“It was a fairly new concept to be honest and we were unsure of how much demand there would be,” says the company’s engineering manager Barry Rushton. “For these reasons we didn’t want to outlay excessive capital designing and building a new production process.”

With this in mind, Mr Rushton decided to try replicating the required process using a trial 520 series pump from Watson-Marlow, a model designed specifically to meet the needs of the process sector.

“We took a 520 series pump on trial for a month,” says Mr Rushton. “We needed a pump which could operate at a variable flow rate depending on the volume, speed and time of our production. We tried it using a selection of different oils and it performed very well. I was particularly interested in achieving accurate dosing of each 300ml volume as we have to declare a given weight for the product within ±2%.”

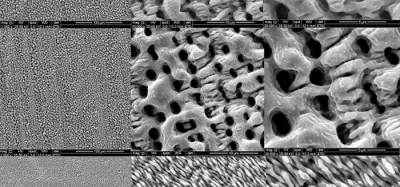

Watson-Marlow’s 520 series pumps are fitted as standard with the 520R pumphead, which accepts up to 9.6mm bore tubing for flow rates up to 3.5 litres/min. The 520R continues Watson-Marlow’s low shear, high reliability pumphead design for high accuracy delivery and long tube life. A key feature of the 520 series pump is its Memo Dose facility, which has helped Lea Green to benefit from accurate and repeatable dosing capability.

Another factor that impressed the team at Lea Green Foods was the design of the filling nozzle. Here, a small quantity of fluid is sucked back up into the tube to prevent any drips after dosing. “The fact that we have no drips not only means less product waste, but also creates a clean process, something that is pretty important in the food industry,” says Mr Rushton. “We also specified food quality 9.6mm bore Marprene as a tubing material.”

Manufacturing processes at Lea Green Foods comply with stringent food hygiene standards. For over six years the company has continually achieved EFSIS Higher Level BRC standards. When linked to its own HACCP System and other control systems, it means the company has an excellently managed food manufacturing site that regularly pleases customer auditing teams.

With demand beginning to rise for the new products, Lea Green Foods requested an extension to the pump trial period, keeping the Watson-Marlow 520 series model for a further three months.

“The success of the product meant we committed to buying the pump,”concludes Rushton. “Since then it’s been fabulous for us. It now runs for a few hours at least four days a week, with demand for the products continuing to grow.”

www.watson-marlow.co.uk