EHEDG publishes new hygienic building guidelines for food production

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 18 December 2014 | BLÜCHER | No comments yet

The European Hygienic Engineering & Design Group (EHEDG) has released a new set of guidelines on hygienic design principles for food factories…

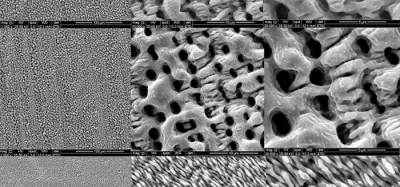

The European Hygienic Engineering & Design Group (EHEDG) has released a new set of guidelines on hygienic design principles for food factories. Within the last years, the focus on hygiene in buildings has accelerated. Examples of listeria and other bacteria spread through condensate, HVAC and drainage systems have made hygiene in buildings an essential issue in food safety. The new guidelines were created in a co-operation between the members of EHEDG. BLÜCHER, a manufacturer of stainless steel drainage systems, was part of the working group behind the new guidelines.

EHEDG is an organisation founded in 1989 with the aim to promote hygiene during the processing and packing of food products. The group is a consortium of equipment manufacturers, food industries, research institutes as well as public health authorities. The members of EHEDG work together to promote food safety by improving hygienic engineering and design in all aspects of food manufacture. Originally, the group focused its efforts on the improvement of hygiene in food processing equipment. However, in recent years, EHEDG has turned its attention to viewing the entire food production facility as a whole.

A tool for hygienic design

The work on the new guidelines started in 2012 and the result is to be a tool for all parties involved in the design, construction and maintenance of food production facilities. By adhering to the hygienic design principles, food factories can guard themselves against a number of internal and external factors as well as provide security against contamination and contribute to the maintenance of hygienic conditions. Best practice in the facilities of some of the world’s leading brands have provided the basis for the guidelines.

“Hygiene is essential in all aspects of the design of food production equipment and facilities”, says Key Account Manager at BLÜCHER, Palle Madsbjerg. He was part of the working group behind the new guidelines. “We have taken part in the work in EHEDG for years and share the knowledge of our product research to contribute to the group’s work”, Palle Madsbjerg continues. BLÜCHER’s client list includes a number of multinational companies and the company has contributed to the development of best practice in relation to their clients’ drainage systems. “Earlier the drain might not have been considered important in relation to hygiene. However, a poorly designed drain can harbour bacteria and be a source of contamination if it is not properly cleaned”, Palle Madsbjerg says.

In addition to its membership of the EHEDG, BLÜCHER is also certified in Hazard Analysis and Critical Control Points (HACCP), a method of analysing and identifying food security risks. “In our view, the EHEDG guidelines contribute to HACCP by focusing on hygienic design. This tool gives the HACCP responsible a possibility to evaluate if the hygienic level is sufficient when changes and expansions are made in the food processing areas. So we are sure that the EHEDG guidelines will contribute to a better building hygiene in production facilities where drainage is essential”, says Palle Madsbjerg.

The EHEDG guidelines are available to order as download via www.ehedg.org.