Stability of pork during frozen storage

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 6 September 2011 | Lene Meinert, Consultant, Danish Meat Research Institute | 1 comment

Freezing is a well-known and widespread preservation method, prolonging the shelf-life of meat and many other food items. Freezing is popular, as it allows meat to keep a close-to-fresh quality for a long time, and it also allows long distance transports. However, depending on the time and temperature combinations during frozen storage, changes in meat quality can indeed occur. These changes include lipid oxidation, a major cause of deterioration of meat generating the undesired rancid taste and odour. It is important to note that freezing, which we use for food storage and distribution today, is not an infinite preservation method and quality reductions, made before freezing, do not disappear.

In order to understand which factors may affect the stability of pork during frozen storage, it is important to look at the composition of pork. Pork consists primarily of water, protein and fat, the proportion of the three vary greatly between the different cuts, some being more fatty e.g. pork belly than others e.g. pork loin. The composition of fat, or fat quality, has a huge influence on shelf-life and thereby also storage time, as the unsaturated fat content is prone to oxidation. Furthermore, pork also contains components that may promote oxidation such as iron. Finally, the amount of water influences the freezing process, as high water content requires increased freezing times.

Freezing is a well-known and widespread preservation method, prolonging the shelf-life of meat and many other food items. Freezing is popular, as it allows meat to keep a close-to-fresh quality for a long time, and it also allows long distance transports. However, depending on the time and temperature combinations during frozen storage, changes in meat quality can indeed occur. These changes include lipid oxidation, a major cause of deterioration of meat generating the undesired rancid taste and odour. It is important to note that freezing, which we use for food storage and distribution today, is not an infinite preservation method and quality reductions, made before freezing, do not disappear. In order to understand which factors may affect the stability of pork during frozen storage, it is important to look at the composition of pork. Pork consists primarily of water, protein and fat, the proportion of the three vary greatly between the different cuts, some being more fatty e.g. pork belly than others e.g. pork loin. The composition of fat, or fat quality, has a huge influence on shelf-life and thereby also storage time, as the unsaturated fat content is prone to oxidation. Furthermore, pork also contains components that may promote oxidation such as iron. Finally, the amount of water influences the freezing process, as high water content requires increased freezing times.

Freezing is a well-known and widespread preservation method, prolonging the shelf-life of meat and many other food items. Freezing is popular, as it allows meat to keep a close-to-fresh quality for a long time, and it also allows long distance transports. However, depending on the time and temperature combinations during frozen storage, changes in meat quality can indeed occur. These changes include lipid oxidation, a major cause of deterioration of meat generating the undesired rancid taste and odour. It is important to note that freezing, which we use for food storage and distribution today, is not an infinite preservation method and quality reductions, made before freezing, do not disappear.

In order to understand which factors may affect the stability of pork during frozen storage, it is important to look at the composition of pork. Pork consists primarily of water, protein and fat, the proportion of the three vary greatly between the different cuts, some being more fatty e.g. pork belly than others e.g. pork loin. The composition of fat, or fat quality, has a huge influence on shelf-life and thereby also storage time, as the unsaturated fat content is prone to oxidation. Furthermore, pork also contains components that may promote oxidation such as iron. Finally, the amount of water influences the freezing process, as high water content requires increased freezing times.

The freezing process

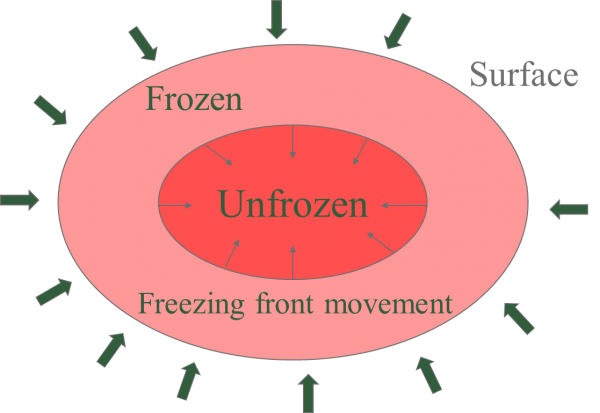

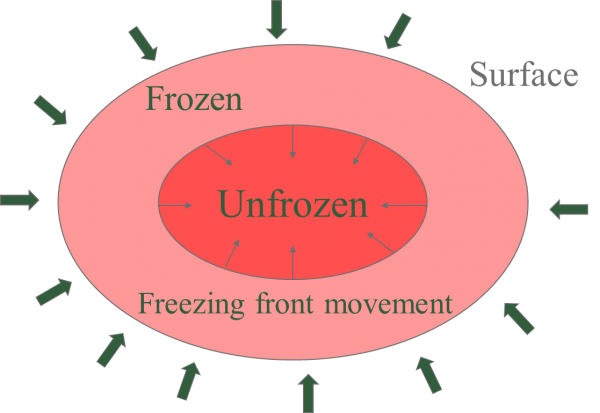

The freezing process is influenced by several factors including 1) the size of the meat cuts, 2) temperature differences between the meat surface and meat core, and as previously mentioned, 3) the content of water in the meat. During the freezing process, the water will gradually change into ice, see Figure 1.

Figure 1 The freezing process in a piece of meat

The speed by which the meat is frozen is closely related to the freezing method used. An example of this is the time used for reaching -18°C. One of the fastest methods is freezing with cryogen, in two hours a pork loin of approximately three kilograms will reach -18°C. In comparison, using air blast will take 17 hours to reach -18°C, and still air in a freeze room will take 24 hours. That is, if the loins are not packed together in cardboard boxes and stacked on pallets – then the time to reach -18°C is much longer with a worst case scenario of several days before all meat cuts are frozen.

Another example of an industrialised and fast method for freezing meat is the impingement freezer, in which meat cuts are placed individually on a conveyer belt transported through a tunnel with air blast. The meat is frozen within a short time e.g. one hour depending on the size of the individual cuts.

Effects on shelf-life during frozen storage

Generally, the shelf-life of meat is limited by the growth of bacteria and chemical changes in the meat. In frozen meat, it is the chemical changes that prevail. However, chemical reactions are slowed down closely related to the lowering of the temperature. Furthermore, the oxidation reactions are slowed or completely inhibited by the absence of oxygen meaning that the packaging materials also influence the shelf-life.

Most bacteria do not grow well at temperatures below 0°C, and microbial growth at freezing temp – eratures is more commonly related to moulds and yeasts. Some processed products e.g. bacon are more likely to support microbial growth below zero degrees, as these products might contain so-called cryoprotectants, e.g. sugar compounds, that depress the freezing point of water1. It is important to note that if sugar is added to bacon it is because of the taste and not because of the effect on freezing, and furthermore that salt will also lower the freezing temperature.

Chemical changes, and especially lipid oxidation, can still occur at low temperatures and even below -20°C. As the temperature is lowered, the reactions do slow down. However, the concentration of components initiating the oxidation reaction, so called pro-oxidants, increases due to the freezing of water leading to ongoing reactions.

Oxidation progresses in several steps, each step generating oxidation products with different properties. In the early steps, the oxidation products (also called primary oxidation products) do not generate noticeable changes to the meat. However, later on in the process when the secondary oxidation products are formed, the rancid taste and odour will become apparent to the user of the meat irrespective of the user being a meat processing plant or a consumer. Therefore, if oxidised meat or fat are used in sausage production for example, there is a great risk of the sausages having a rancid flavour. Based on an experiment with vacuum packed frozen pork patties, it was shown that lipid oxidation measured as secondary oxidation products (TBARS) did develop at -23°C. And interestingly, temperature fluctuations between two storage temperatures accelerated the oxidation which resulted in concentrations of TBARS intermediate to the TBARS concentrations measured in the patties stored constantly at one of the two storage temperatures (e.g. -10°C and -20°C). On the other hand, at -40°C no increase in TBARS was observed2 (see Figure 3).

Figure 3 Lipid oxidation measured as TBARS in pork patties as a function of storage time

Even though the patties of pork belly contained 23 per cent fat, and the patties from loin contained two per cent fat, the TBARS increased in a very similar manner and to the same level after approximately 270 days (not shown). This was due to the fatty acid composition, as much of the fat from the pork belly was saturated and therefore not prone to oxidation. So in this case the higher fat content did not lead to a higher degree of oxidation. Indeed, it has been shown that pure pork lard, which is mainly composed of saturated fat, has a longer shelf-life than pork cuts containing a small fraction of fat (e.g. loin), as this fat intra muscular fat is generally unsaturated and may oxidise.

Shelf-life depends on temperature, packaging method and meat quality

The big question is for how long can pork be stored in the freezer? Danish guidelines from the 1960’s show that at -18°C, the shelf-life of pork is five months whereas when lowering the temperature by only 2°C to -20°C, the shelf-life increases to seven months. Even though these shelf-life indications were based on half carcasses, and therefore cannot be directly translated to smaller cuts, the exponential development in shelf-life related to temperature is interesting and believed to be valid for pork in general (Figure 4). For smaller cuts like pork chops, an estimated shelf-life for storage at -20°C is 10 months3. This exponential relation between temperature and shelf-life clearly indicates that temperature is very important for the stability of pork during frozen storage.

Figure 4 Development in shelf-life as a function of temperature during frozen storage from -15°C to -25°C2

At DMRI, frozen pork loins were stored in the freezer (approximately -18°C) for 4.5 years, during the first two years in oxygen permeable film and the following 2.5 years in air tight vacuum packs. The loins were cut into chops, pan-fried and assessed by a trained sensory panel, and it was shown that oxidation had progressed in the outer layer of the meat leading to a rancid / old / cardboard-like taste. However, the core part of the meat did not have an oxidised flavour, though a bit of a ‘boring’ taste.

One could assume that the shelf-life of pork during frozen storage would be somewhere in between 5 – 10 months and 4.5 years. However, there are no well-documented guidelines for storage time in relation to different pork products (cuts with more or less fat), packaging methods and temperatures.

Quality after thawing

It is important to bear in mind that the quality of thawed meat is never better than the quality of the meat at the time of freezing. So the factors with the highest impact on the quality of thawed meat are: 1) the quality of the meat at the time of freezing, 2) the freezing process, especially freezing speed and 3) storage conditions.

One of the major quality concerns is the drip loss after thawing, as drip loss equals money loss. The amount of water lost from the meat is directly related to the speed of freezing. An example based on a DMRI experiment is shown in Table 1.

As can be seen from Table 1, the loss of water is minimised by the faster freezing method.

Table 1. Pork loins. Loss of water based on drip loss after thawing and cooking loss after heat treatment (medium done, approx. 68°C core temperature) in relation to two different freezing methods.

|

Frozen with air blast |

Frozen with cryogen |

|

| Time of freezing (hours) |

12 |

2 |

|

|

|

|

| Drip loss (%) |

2.4 |

1.6 |

| Cooking loss (%) |

16.8 |

15.2 |

| Sum of loss (%) |

19.2 |

16.8 |

Another factor of importance for meat quality after frozen storage is the packaging materials and as already mentioned, packaging materials influence the oxidation process through the degree of oxygen permeability. Furthermore, the choice of packaging material also affects the loss of water, which is illustrated in Table 2, based on data from a DMRI experiment.

Table 2. Drip loss related to packaging method after frozen storage; PE-Wrap (polyethylene, oxygen permeable film) versus vacuum pack (oxygen impermeable film).

|

PE-Wrap |

Vacuum |

|

| Drip loss(%) |

14.8 |

11.8 |

DMRI engineers developed the ‘EZ drip loss method’4, which has made drip loss measurements easy as well as reliable.

Summing up

The shelf-life of frozen pork and the quality of the thawed meat depend on many factors, starting with the meat quality at the time of freezing, the freezing method used, the packaging method used and the conditions during storage. It is important to remember that meat quality does not improve during frozen storage, nor does poor treatment of the meat before freezing disappear.

References

1. Jay, J.M. (2000). Modern Food Microbiology. 6th edition. Aspen Publishers, inc. pp.679

2. Hansen, E., Lauridsen, L., Skibsted, L.H., Moawad, R.K., Andersen, M.L. (2004). Oxidative stability of frozen pork patties: Effect of fluctuating temperature on lipid oxidation. Meat Science 68: 185-191

3. Bøgh-Sørensen, L., Jensen, J.H., Jul, M. (1983). ”Chapter 5: Freezing” in Konserverings teknik 1, 2nd edition. DSR Forlag, Copenhagen

4. Christensen, L.B (2003). Drip loss sampling in porcine longissimus dorsi. Meat Science 63: 469-477

Dr. Lene Meinert has been a consultant, since 2008, at the Danish Meat Research Institute, centre of meat quality. Lene has a masters and PhD from the University of Copenhagen within the field of food science with focus on sensory science, chemistry and microbiology. Today, she is involved in several R&D projects including development of rapid sensory methods for industrial application, mathematical model for shelf-life prediction of fresh pork, bioactive components in pork and bi-products and finally boar taint detection by the human nose method. Lene has a wide experience in the coordination of research projects involving both universities and the industry.

Thank you for a very interesting and informative article. I have an excellent source of frozen pork chops & mince, but have perceived an intensity of flavour in the chops, but not so with the mince.

It is as if the taste has become much stronger.

I understand the meat, from a rare breed of pig & organically reared, is frozen in a normal manner, as against quick freeze methods.

Thanking you.