Problems with plate heat exchangers

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

Posted: 6 September 2011 | Wouter N.A. Burggraaf, Burggraaf & Partners B.V. | No comments yet

In the food industry, plate heat exchangers are often used for cooling or heating liquid food products. Plate heat exchangers are relatively cheap and can also be applied for heat recovery. The industry has tried to solve a number of food safety problems, but it has not succeeded in all cases. Problems around the gaskets have been solved. It is clearly understood that elastomers do not have an unlimited lifespan. The gasket should be replaced preventatively. The gasket is no longer glued and nowadays, there are rapidly exchangeable gaskets. Specialist companies can change gaskets quickly and neatly.

The single rubber seal between the product side and the cooling- or heating medium has been replaced by a double gasket with a leak detection chamber in between. It remains important that the operator is aware of any leakage if it occurs and inspects this daily.

In the food industry, plate heat exchangers are often used for cooling or heating liquid food products. Plate heat exchangers are relatively cheap and can also be applied for heat recovery. The industry has tried to solve a number of food safety problems, but it has not succeeded in all cases. Problems around the gaskets have been solved. It is clearly understood that elastomers do not have an unlimited lifespan. The gasket should be replaced preventatively. The gasket is no longer glued and nowadays, there are rapidly exchangeable gaskets. Specialist companies can change gaskets quickly and neatly. The single rubber seal between the product side and the cooling- or heating medium has been replaced by a double gasket with a leak detection chamber in between. It remains important that the operator is aware of any leakage if it occurs and inspects this daily.

In the food industry, plate heat exchangers are often used for cooling or heating liquid food products. Plate heat exchangers are relatively cheap and can also be applied for heat recovery. The industry has tried to solve a number of food safety problems, but it has not succeeded in all cases. Problems around the gaskets have been solved. It is clearly understood that elastomers do not have an unlimited lifespan. The gasket should be replaced preventatively. The gasket is no longer glued and nowadays, there are rapidly exchangeable gaskets. Specialist companies can change gaskets quickly and neatly.

The single rubber seal between the product side and the cooling- or heating medium has been replaced by a double gasket with a leak detection chamber in between. It remains important that the operator is aware of any leakage if it occurs and inspects this daily.

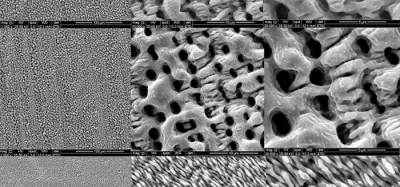

The exact flow pattern remains a question point. Equipment suppliers have carried out a lot of research and development to increase the efficiency of the plates and to reduce the costs. The flow distribution over a plate has been improved in some cases, but that does not alter the fact that the product in some places flows slower or sometimes does not flow at all. The latter is destructive, because at the optimal growth temperature of a typical microorganism, small amounts of stagnant product can lead to huge numbers. Experience shows that after six to eight hours of production that this not negligible in the bulk of the flow: e.g. there are so many thermophilic microorganisms grown in pasteuriser plates that the hot holding section (70°C, 20 minutes) is insufficient to ensure complete inactivation. This means a level of more than 107 microorganisms per millilitre just before the hot holding section. The plate heat exchanger as a pasteuriser seems to be an excellent fermentor and selector for thermophilic microorganisms. Thermophilic microorganisms are often a house culture in the dairy industry.

When a product starts sticking to the wall due to heat deterioration, it becomes very difficult or even impossible to remove the soil completely. The maintenance department discovers this at the moment they are replacing the gaskets. Recently, Ecolab has introduced a new CIP chemical, Exelerate®, which is able to penetrate better in this type of soil and remove it better than all other chemicals at the moment. Avoiding fouling is still the best approach. Numerous studies are carried out. Interesting is the comparison with our own experiments with native starches with some results of the Dutch food research institute NIZO with dairy proteins. When both products feel a temperature of approximately 104°C at the wall, fouling starts. By controlling the temperature of the heating medium, it is possible to avoid fouling in heating to pasteurisation or swelling temperature.

When the plates are not fouled, the question is still whether the plate heat exchangers are cleanable to a microbial level. As far as I know, there has not been a single plate heat exchanger that has passed the EHEDG cleanability test. For the user, there is not much left than to thermally disinfect a plate heat exchanger (e.g. by hot cleaning). Because due to its configuration a plate heat exchanger is not able to be drained completely, the last nonsterile post rinse water remains in the equip – ment. Combined with not fully cleaned equipment, these are ideal circumstances for those microorganisms to grow. Therefore a plate heat exchanger should be rinsed and thermally disinfected again just before use.

In response to the call to make plate heat exchangers cheaper, equipment suppliers have reduced the plate thickness from the original 1.1 millimetres to even 0.3 millimetres. The cold deformation of the plate brings a lot of tension in the material that increases the chance for stress corrosion and a greater sensitivity to pit corrosion, and sometimes, artefacts are found in the thin 2B-finished cold rolled stainless steel (most common plate material). Most equipment suppliers have a quality assurance programme by random checking the plate for irregularities. But for the user, it is important that none of the 600 plates are leaking. In my own experience, I have seen brand new, never used plate heat exchangers leaking. The first systematic research into plate heat exchangers in Denmark showed that 90 per cent of all the inspected plate heat exchangers were leaking. The situation in Netherlands was no better. Regular inspection brought the percentage leaking through inspection back to 10 to 30 per cent.

There are three methods to check plate heat exchangers for possible leakage. Two methods work with a light gas as a medium (hydrogennitrogen mixture or helium). A sensitive method with two disadvantages:

- the system should be absolutely dry, because the solubility of the gases is better in water than in air

- the gasket leaks the light gases, and because this varies per type of elastomers, it could disturb the measurement

A third method works with (food-grade) colour agents. The installation is brought in overpressure several times (at the moment, 6 bar overpressure; and we have challenged them for some applications to go to 15 – 25 bar). The liquid with the colour agent is re-circulated (in overpressure); the liquid at the other side is circulated too and is led through a spectrophotometer. The method is so sensitive that with the receiving (concentration) peak within five plates accuracy, the leaking plate could be found.

In practice, the first two methods are useful to test the dry brand new equipment. The latter is good for testing the equipment at regular base. However, if you find a leak, you are already too late. It is not preventive.

Experience with all different plate heat exchangers show that the thinner the plate, the harder it is to find leaking plates. The traditional plate thickness of 1.1 millimetres rarely shows leakage, even with plates more than 10 years old.

The food industry is partly aware of the risk of leaking plates and has therefore proposed with the use of a regenerative to increase the pressure of the pasteurised product towards the unpasteurised product by the placing of a booster pump. Therefore, in case of leakage, no unpasteurised product could enter the pasteurised product. Most countries have prescribed this for dairy plants.

The only problem is that microorganisms do not always move from the pressure difference and could move through tiny small crevices. If a crevice is caused by stress corrosion or pit corrosion becomes so big that a larger quantity of liquid flows, the microorganisms cannot swim against the flow direction. But at 6 bar pressure difference in the crevice, up to two micrometers and certain plate thickness, thanks to the capillary working, there will be no product flow, while a small microorganism of 0.5 micrometers could pass. This has been observed in the (nonsterile) cooling section of a plate heat exchanger of a UHT installation. Some microorganisms are chemotactic and swim in the direction of the higher concentration (penetrating from the sterile product through a crevice into the cooling medium). This is the reason why EHEDG has written a guideline to monitor the cooling or heating medium carefully by e.g. a pHmeasurement. The regenerative is not separated by a single plate, but by a medium that is controlled. The disadvantage is the double amount of heat exchanging surface and the lower efficiency.

Some equipment suppliers have responded to this to work with a double plate of 0.3 millimetres without the medium in between. The theory was that as soon as one of plates was leaking, this is visual to the outside, identical to the leakage detection of the gaskets, but in practice was more recalcitrant. When inspected, it seems that often between the two plates, a thick layer of soil is present and both plates close to each other are leaking.

Afterwards it is easy to explain. As soon as a leakage occurs and the product enters between the plates, this shall not move quickly outside, thanks to the capillary working. During the (hot) cleaning, the product dries in the room in between and in combination with chloride from product or disinfectant, some place further on, pit corrosion is initiated. Apparently, this was already noted, because there was also for a while a triple plate.

When purchasing new equipment, it is worth for the dairy industry with its large capacities (and regenerative) looking at alternatives. Tubular heat exchangers can be such an alternative. They have several advantages: the thicker wall, combined with annealing, means less chance of stress corrosion or pit corrosion. But more interesting is that good design of a tubular heat exchanger means there is no stagnant product and with good control, a tubular heat exchanger can run for 160 hours without cleaning. If you compare that with the need to clean a plate heat exchanger every six to eight hours, the cost of ownership becomes more favourable than you would expect.

Burggraaf & Partners has four specialists in the field of hygienic and aseptic design. They perform quick scans in food and Pharma factories in the occasion of (almost) recalls, and advise on the construction engineers on the hygienic design and cleanability of its machines. The next high level international course for Hygienic Design is in Amsterdam (in com – bination with a visit and case study in the pilot plant of the NIZO Institute) 5 – 8 September 2011 (see www.ehedg.nl).

The European Hygienic Engineering & Design Group (EHEDG) is a consortium of food industry, engineering and research laboratories, which have the goal to publish guidance in safe food production.

References

• EHEDG guideline no. 2, A method for assessing the in-place cleanability of food processing equipment

• EHEDG guideline no.1 Microbiologically safe continuous pasteurization of liquid food

Wouter Burggraaf is a board member of EHEDG Netherlands and has more than 25 years experience in Hygienic Design. He gives numerous training and education sessions in Dutch, English and German (see www.burggraaf.cc).